A kind of printing plate protective coating and preparation method thereof

A protective coating and printing plate technology, applied in the field of printing plate protective coating and its preparation, can solve the problems of printing plates not having comprehensive properties, achieve good chemical inertness and thermal stability, highlight weather resistance, and improve strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

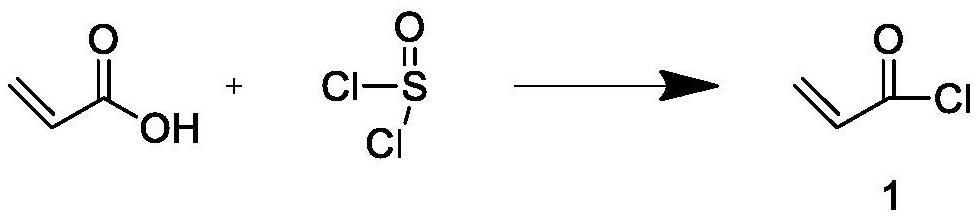

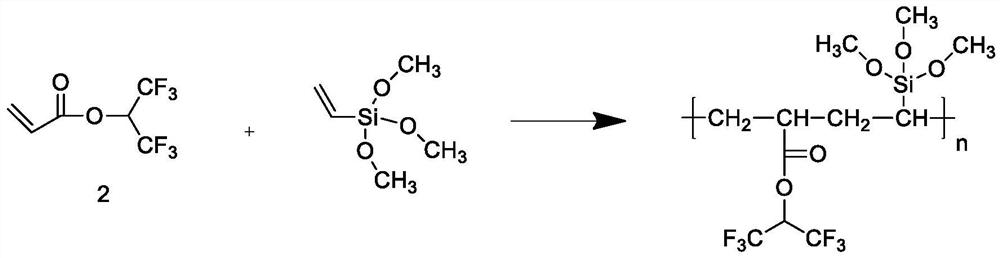

[0036] The modified acrylic resin is prepared by the following steps:

[0037] Step A1: Take a three-mouth flask with a stirrer and a thermometer, add acrylic acid to the three-mouth flask, and then add dichlorosulfoxide to the three-mouth flask, control the stirring speed of 500r / min, the reaction temperature is 55 °C, the reaction is 40min, and the intermediate 1 is obtained, wherein the dosage ratio of acrylic acid and dichlorosulfoxide is 1mol: 1.15mol;

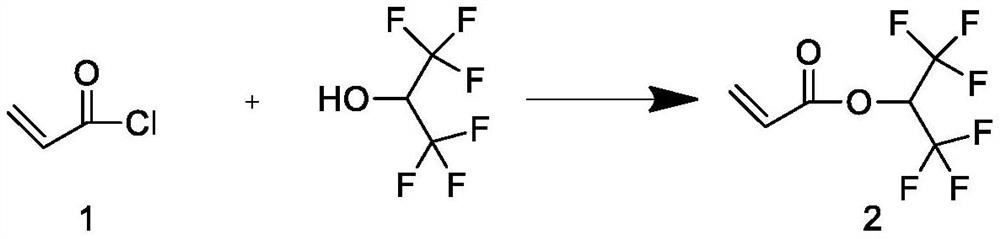

[0038] Step A2: Take hexafluoroisopropanol and tetrahydrofuran mixed and added to the three-mouth flask, add an aqueous sodium hydroxide solution to the three-mouth flask, adjust the pH of the mixture to 10, at a stirring speed of 120r / min, the water bath temperature is 45 °C, use a drip funnel to add the intermediate to the three-mouth flask dropwise, after the drop addition is completed, the insulation reaction is 1h, the reaction mixture is washed with deionized water, standing and stratifying, the layer of oily liquid is ...

Embodiment 2

[0041] The modified acrylic resin is prepared by the following steps:

[0042] Step A1: Take a three-mouth flask with a stirrer and a thermometer, add acrylic acid to the three-mouth flask, and then add dichlorosulfoxide to the three-mouth flask, control the stirring speed of 600r / min, the reaction temperature is 56 °C, the reaction is 45min, and the intermediate is obtained 1, wherein the dosage ratio of acrylic acid and dichlorosulfoxide is 1mol: 1.15mol;

[0043] Step A2: Take hexafluoroisopropanol and tetrahydrofuran mixed and added to the three flasks, add aqueous sodium hydroxide solution to the three flasks, adjust the pH of the mixture to 10, at a stirring speed of 130r / min, the water bath temperature is 48 °C, use a drip funnel to add intermediates to the three flasks dropwise, after the drip is completed, Insulation reaction 1.2h, the reaction mixture was washed with deionized water, standing and layered, the layer of oily liquid was removed, and intermediate 2 was prepa...

Embodiment 3

[0046] The modified acrylic resin is prepared by the following steps:

[0047] Step A1: Take a three-mouth flask with an agitator and a thermometer, add acrylic acid to the three-mouth flask, and then add dichlorosulfoxide to the three-mouth flask, control the stirring speed of 700r / min, the reaction temperature is 58 °C, the reaction is 50min, and the intermediate is obtained 1, wherein the dosage ratio of acrylic acid and dichlorosulfoxide is 1mol: 1.15mol;

[0048] Step A2: Take hexafluoroisopropanol and tetrahydrofuran mixed and add to the three-mouth flask, add an aqueous sodium hydroxide solution to the three-mouth flask, adjust the pH of the mixture to 10, at a stirring speed of 150r / min, the water bath temperature is 50 °C, use a drip funnel to add intermediates to the three-mouth flask dropwise, and after the drop is completed, The insulation reaction was 1.5h, the reaction mixture was washed with deionized water, standing and layered, the layer of oily liquid was removed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com