Preparation method of Ag-modified La-Mg-Ni type hydrogen storage alloy and application of Ag-modified La-Mg-Ni type hydrogen storage alloy as DBFC anode catalyst

A technology of hydrogen storage alloy and preparation method, which is applied in the direction of battery electrodes, liquid chemical plating, metal material coating technology, etc., can solve the problem of low catalytic activity, avoid inert electrodes, avoid the introduction of impurities, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

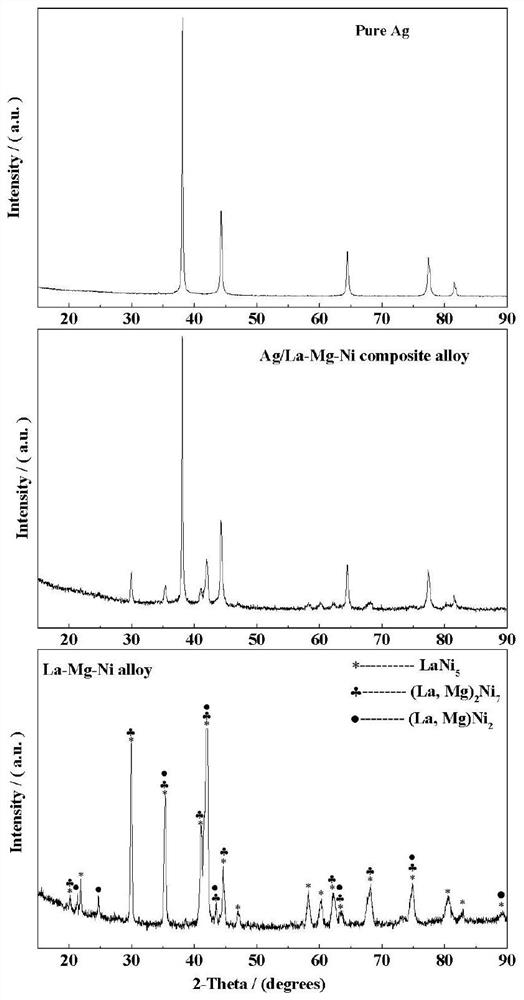

[0035] A kind of preparation method of Ag modified La-Mg-Ni type hydrogen storage alloy of the present invention comprises the following steps:

[0036] 1. Preparation of hydrogen storage alloy: rare earth metal La, metal Co, Mn, Al and intermediate alloy Mg 2.5 Ni is subjected to induction melting to prepare La-Mg-Ni type hydrogen storage alloy; in order to prevent the loss of Mg element during the melting process, 9% of the Mg content is calculated by excessive addition, and the temperature of the induction melting furnace is 660-1600 °C.

[0037] 2.PVP+AgNO 3 / Preparation of La-Mg-Ni mixture:

[0038] a. Preparation of polyvinyl alcohol (PVP) sol: Weigh an appropriate amount of PVP particles and add it to an appropriate amount of distilled water, stir to obtain a uniform PVP sol, seal it for use;

[0039] b. Preparation of AgNO 3 Solution: Weigh an appropriate amount of AgNO with a purity greater than 99.8% 3 Add the powder into distilled water to prepare AgNO with a con...

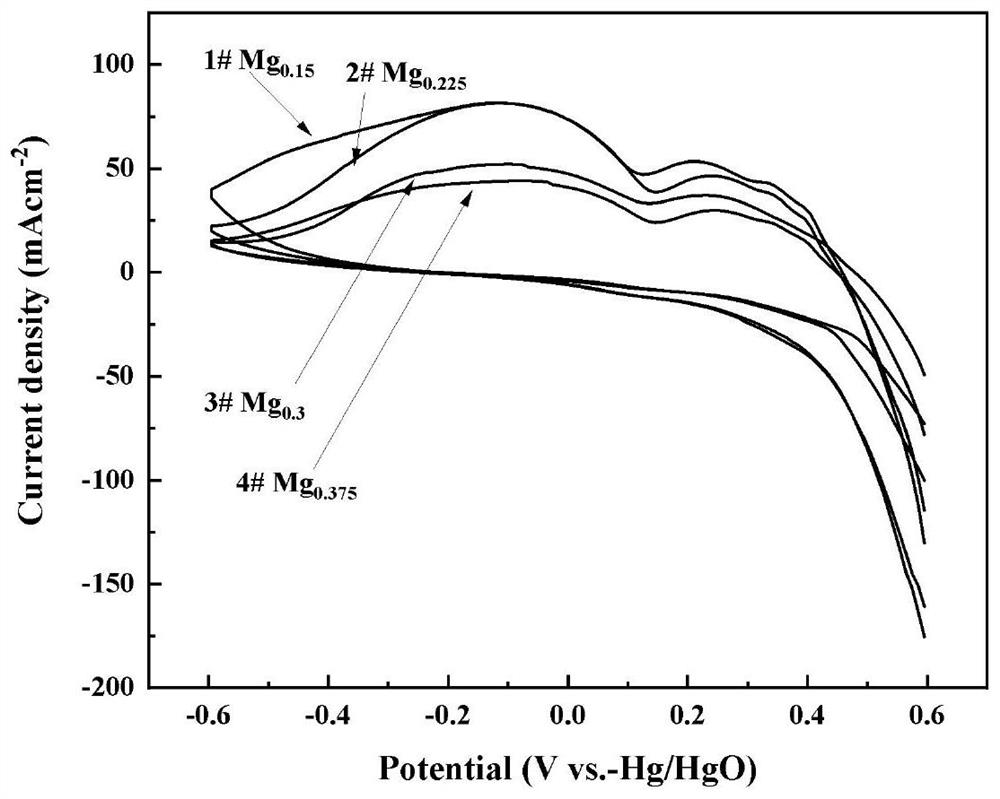

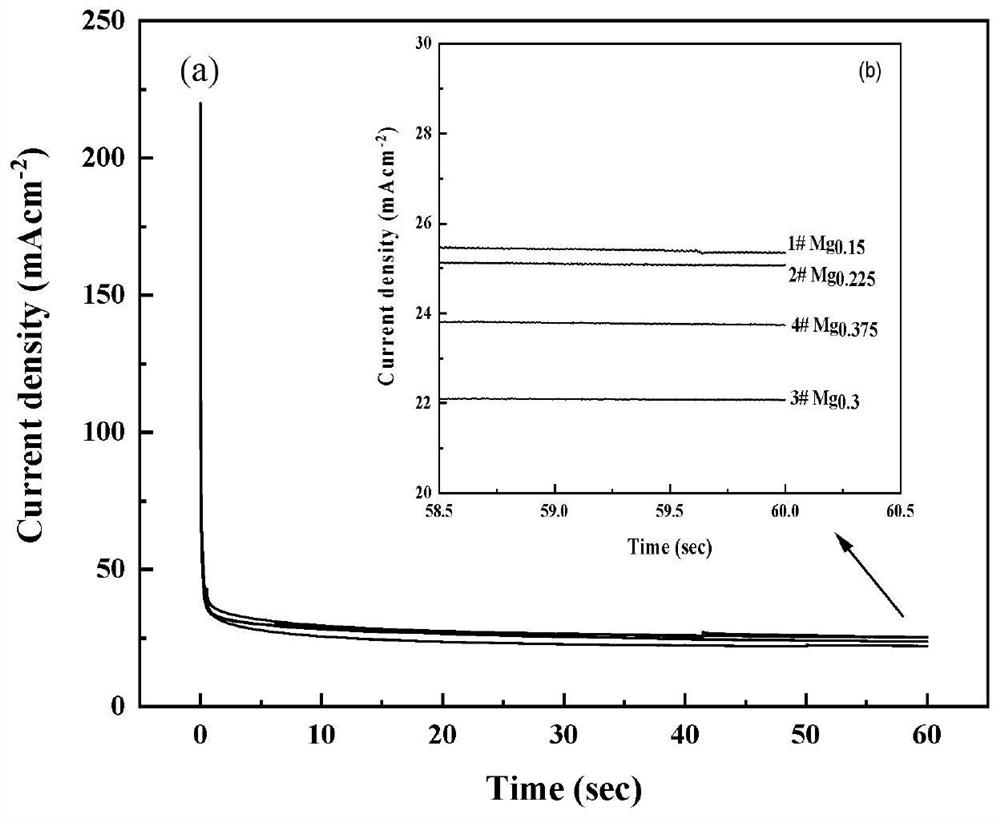

Embodiment 1

[0044] 1. According to the design, each element of the alloy is weighed according to the atomic ratio La: Mg: Ni: Co: Mn: Al = 0.85:0.15:2.485:0.525:0.28:0.21. In order to prevent the loss of Mg element during the smelting process, the excessive addition is calculated 9% of the Mg content; the above-mentioned weighed alloy raw materials were subjected to induction melting to prepare La 0.85 Mg 0.15 Ni 2.485 co 0.525 mn 0.28 Al 0.21 Hydrogen storage alloys.

[0045] 2. Weigh an appropriate amount of PVP particles and add it to an appropriate amount of distilled water, stir to obtain a uniform PVP sol, and seal it for use. Then, prepare AgNO3 solution. Weigh AgNO with a purity greater than 99.8% 3 Add the powder into distilled water to make a uniform silver nitrate solution with a concentration of 5.89mol / L, and transfer the solution into a brown bottle protected from light for later use. Finally, the Ag surface-modified La-Mg-Ni hydrogen storage alloy powder was prepare...

Embodiment 2

[0051] Example 2: Ag / La 0.775 Mg 0.225 Ni 2.485 co 0.525 mn 0.28 Al 0.21 ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com