Intelligent dynamic dimming film and preparation method and application thereof

An intelligent dynamic and light-adjustable film technology, applied in chemical instruments and methods, optics, nonlinear optics, etc., can solve problems such as the weakening of tungsten oxide’s ability to absorb lithium ions, and the reduction of the color adjustment range of color-changing devices with the use of time, etc., to achieve Shorten the migration distance, improve the stability, and improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

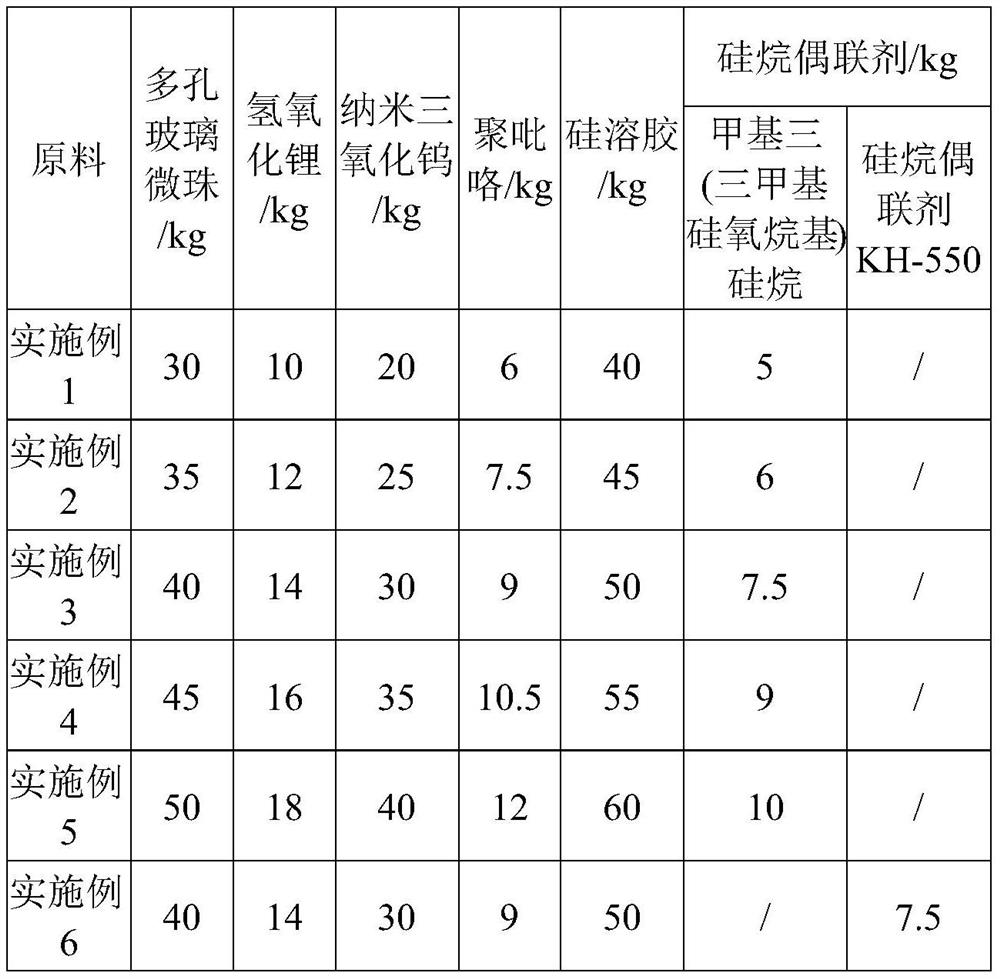

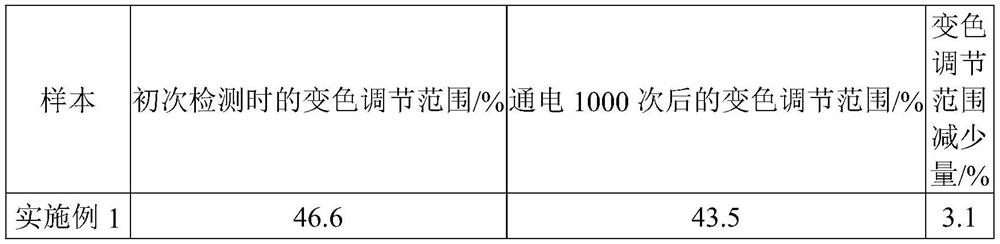

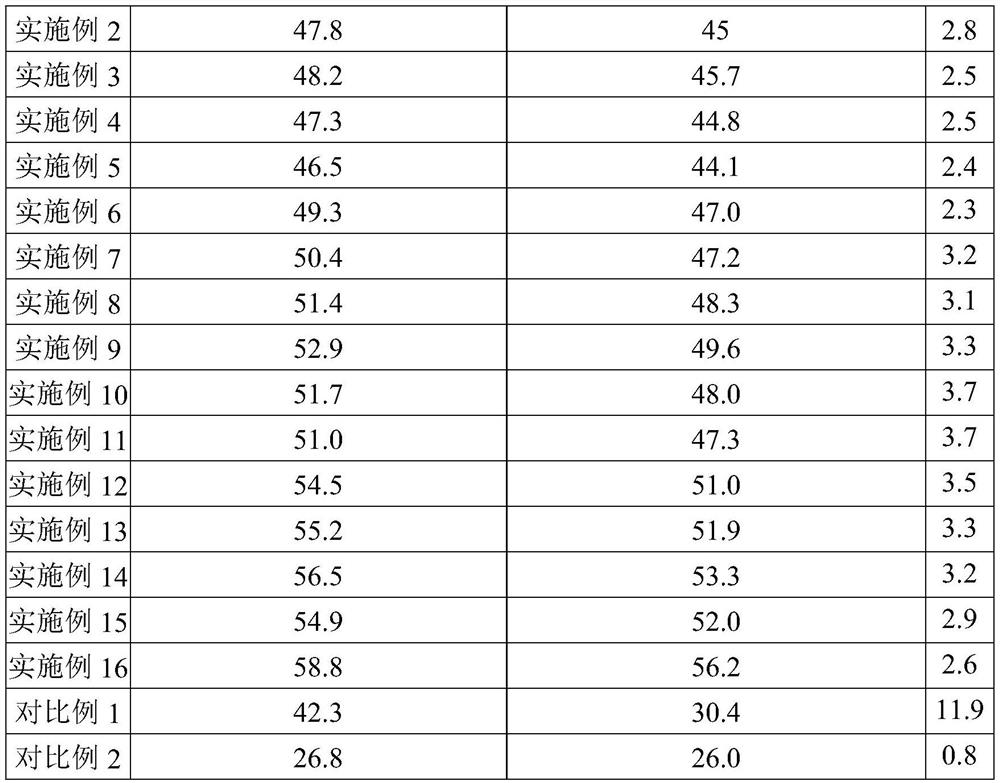

Examples

preparation example Construction

[0039] Preparation Example of Porous Glass Beads

[0040] The following takes preparation example 1 as an example for illustration.

preparation example 1

[0042] The raw materials used in this preparation example can all be obtained from the market. Among them, the glass beads are SOVITEC solid glass beads produced by Kunshan Chuanlinwei Trading Co., Ltd.; the hydrochloric acid is chemically pure 37% Concentrated hydrochloric acid (CP grade) prepared. Porous glass microspheres were prepared as follows:

[0043] (1) Put the glass beads into the crucible, heat at 450-600° C. for 40 h, and cool the glass beads at a cooling rate of 20° C. / min after the heating;

[0044] (2) Put the glass microspheres cooled to room temperature into 2mol L -1 Pickling in a hydrochloric acid solution, pickling for 1.8h, taking out the glass beads for washing and drying, to obtain porous glass beads.

preparation example 2-6

[0046] As shown in Table 1, the difference between Preparation Examples 2-6 and Preparation Example 1 is that the cooling rate is different.

[0047] Table 1

[0048] sample Preparation Example 1 Preparation example 2 Preparation Example 4 Preparation Example 4 Preparation Example 5 Preparation Example 6 Cooling rate / (℃ / min) 15 20 25 30 35 40

[0049] After the porous glass microspheres were prepared, the Beijing Clearing Technology Research Institute was commissioned to test the average porosity of the porous glass microspheres in Preparation Examples 1-6, and the testing results are shown in Table 2.

[0050] Table 2

[0051] sample Preparation Example 1 Preparation example 2 Preparation Example 4 Preparation Example 4 Preparation Example 5 Preparation Example 6 average porosity 42% 45% 48% 52% 55% 58%

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com