High-strength platinum-based electric contact material and preparation method thereof

An electrical contact material, high-strength technology, applied in the field of electrical contact, can solve problems such as poor wear resistance, and achieve the effect of preventing high temperature oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

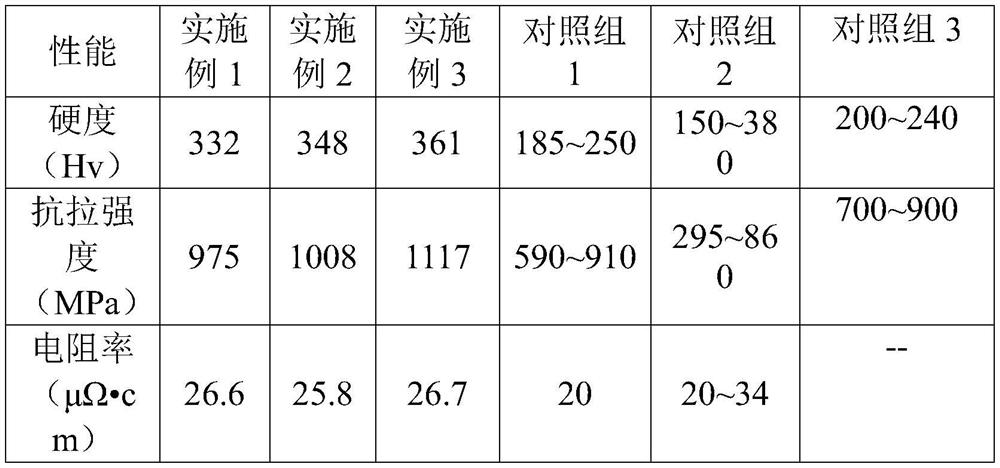

Embodiment 1

[0051] The platinum-based electrical contact material was prepared according to the following steps:

[0052] (1) Dosing according to Pt: 93%, Au: 2%, and Ni: 5%, and wrap the gold and nickel particles with platinum sheets.

[0053] (2) Place the alloy mixture obtained in step (1) in a vacuum melting furnace for melting.

[0054] (3) Put the alloy ingot obtained in step (2) into an alumina crucible, wrap it with alumina powder in advance and cover it with a layer of carbon powder, and place it in a muffle furnace for homogenization heat treatment at 900° C. for 1 hour.

[0055] (4) The alloy ingot after the homogenization treatment in step (3) is cold-rolled on a cold rolling mill, and the homogenization treatment is performed when the deformation reaches 70% during the rolling process, the temperature is 900° C., and the time is 1 h. until rolling The rods were homogenized again at 900°C for 1 hour.

[0056] (5) the step (4) obtained The alloy rods were drawn on a wire ...

Embodiment 2

[0059] The platinum-based electrical contact material was prepared according to the following steps:

[0060] (1) Dosing according to Pt: 93%, Au: 2%, and Ni: 5%, and wrap the gold and nickel particles with platinum sheets.

[0061] (2) Place the alloy mixture obtained in step (1) in a vacuum melting furnace for melting.

[0062] (3) Put the alloy ingot obtained in step (2) into an alumina crucible, wrap it with alumina powder in advance and cover it with a layer of carbon powder, and place it in a muffle furnace for homogenization heat treatment at 900° C. for 1 hour.

[0063] (4) The alloy ingot after the homogenization treatment in step (3) is cold-rolled on a cold rolling mill, and the homogenization treatment is performed when the deformation reaches 70% during the rolling process, the temperature is 900° C., and the time is 1 h. until rolling The rods were homogenized again at 900°C for 1 hour.

[0064] (5) the step (4) obtained The alloy bar is drawn on a wire dra...

Embodiment 3

[0067] The platinum-based electrical contact material was prepared according to the following steps:

[0068] (1) Dosing according to Pt: 90%, Au: 5%, Ni: 5%, wrapping gold and nickel particles with platinum sheets.

[0069] (2) Place the alloy mixture obtained in step (1) in a vacuum melting furnace for melting.

[0070] (3) Put the alloy ingot obtained in step (2) into an alumina crucible, wrap it with alumina powder in advance and cover it with a layer of carbon powder, and place it in a muffle furnace for homogenization heat treatment at 900° C. for 1 hour.

[0071] (4) The alloy ingot after the homogenization treatment in step (3) is cold-rolled on a cold rolling mill, and the homogenization treatment is performed when the deformation reaches 70% during the rolling process, the temperature is 900° C., and the time is 1 h. until rolling The rods were homogenized again at 900°C for 1 hour.

[0072] (5) the step (4) obtained The alloy bar is drawn on a wire drawing mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com