Bismuth oxybromide ultra-thin nano sheet photochromic material rich in oxygen vacancies as well as preparation method and application thereof

A photochromic material, bismuth oxybromide technology, applied in the direction of color-changing fluorescent materials, nanotechnology, chemical instruments and methods, can solve the problems of poor dispersion of bismuth oxybromide, increased cost, unfavorable environmental protection, etc., to achieve photochromic effect good, long cycle life, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

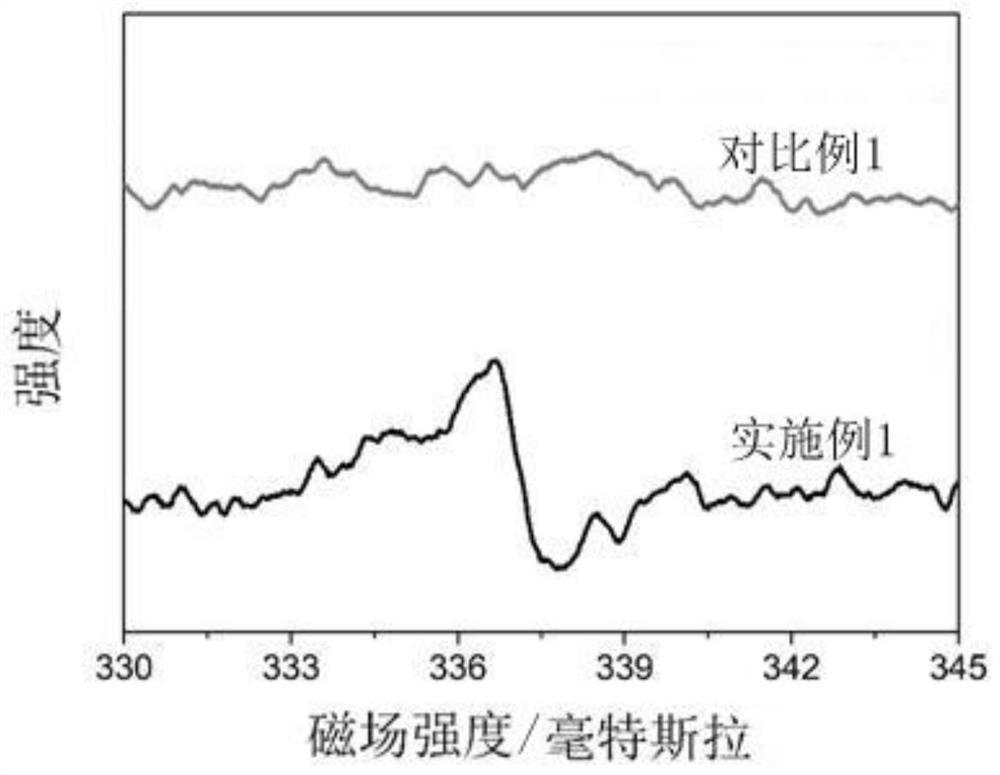

Embodiment 1

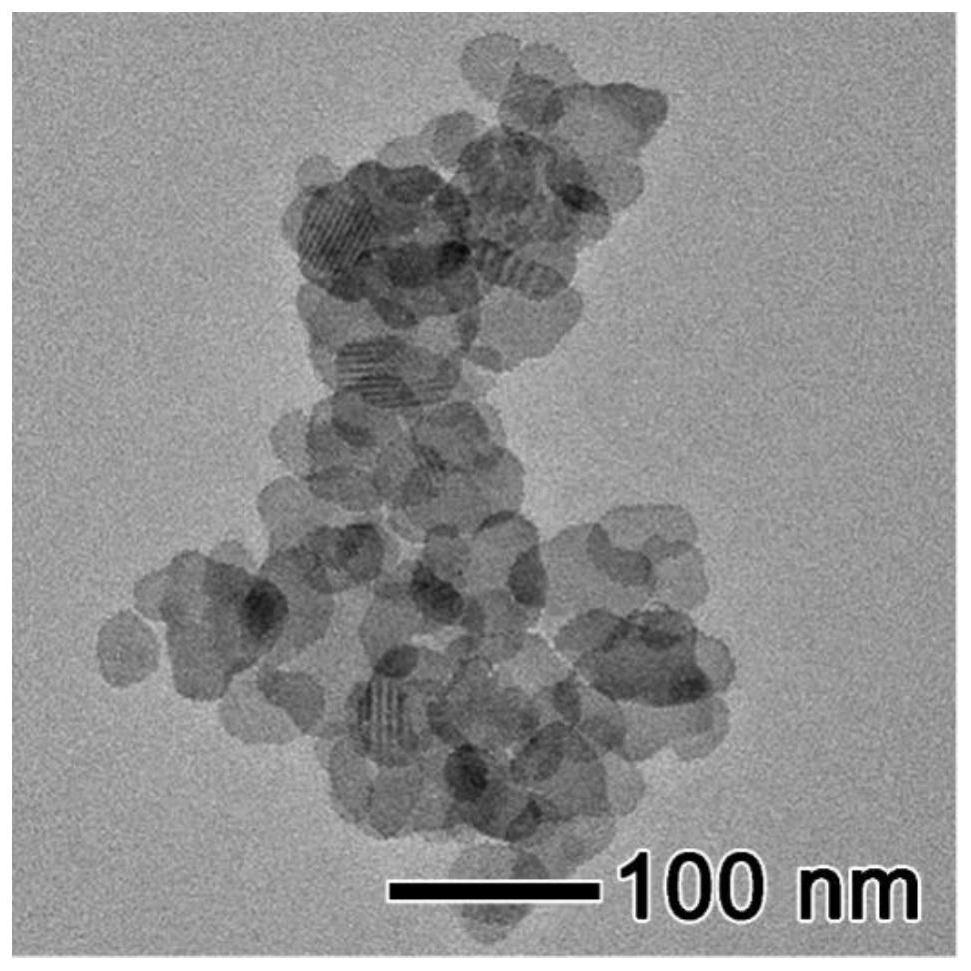

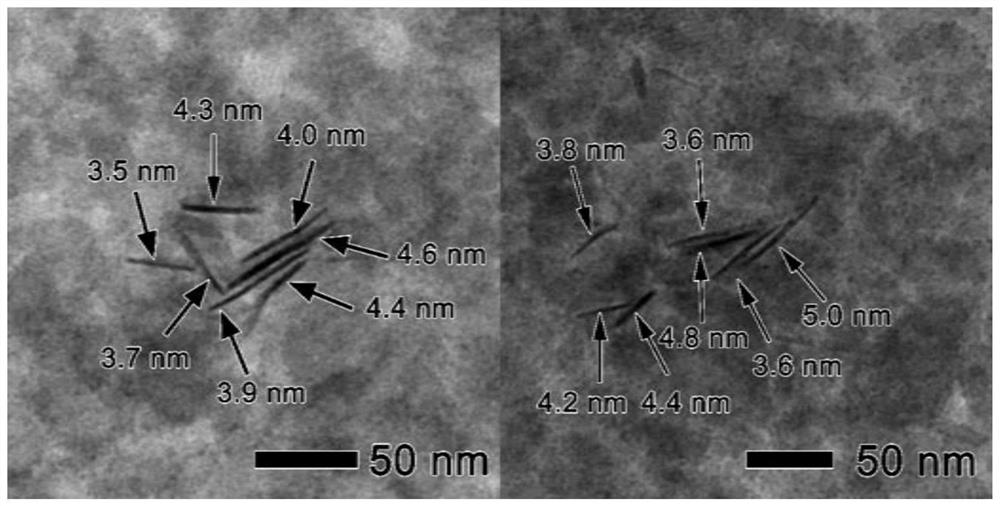

[0040] A method for preparing an oxygen-vacancy-rich bismuth oxybromide ultra-thin nanosheet photochromic material, comprising the following steps:

[0041] (1) Dissolve 0.6g polyvinylpyrrolidone (average molecular weight 30000) and 0.6g mannitol in 30mL water, stir until the solution is transparent, add 0.485g bismuth nitrate pentahydrate, continue stirring until bismuth nitrate pentahydrate is completely dissolved, then add 5mL Aqueous sodium bromide solution with a concentration of 0.2 mol / L was stirred for 30 minutes to obtain a mixed solution.

[0042] (2) The mixed solution in step (1) was transferred to a polytetrafluoroethylene reactor with a volume of 60 mL, reacted at 150° C. for 12 hours, and cooled naturally to room temperature after the reaction was completed.

[0043] (3) Filter the reaction solution obtained in step (2), centrifuge and wash the obtained precipitate three times with a mixed solvent of water and acetone (the volume ratio of water and acetone is 1:...

Embodiment 2

[0052] A method for preparing an oxygen-vacancy-rich bismuth oxybromide ultra-thin nanosheet photochromic material, comprising the following steps:

[0053] (1) Dissolve 0.6g polyvinylpyrrolidone (average molecular weight 130000) and 0.6g mannitol in 30mL water, stir until the solution is transparent, add 0.485g bismuth nitrate pentahydrate, continue stirring until bismuth nitrate pentahydrate is completely dissolved, then add 5mL Aqueous cetyltrimethylammonium bromide solution with a concentration of 0.2 mol / L was stirred for 30 minutes to obtain a mixed solution.

[0054] (2) The mixed solution in step (1) was transferred to a polytetrafluoroethylene reactor with a volume of 60 mL, reacted at 150° C. for 3.5 hours, and cooled naturally to room temperature after the reaction was completed.

[0055] The reaction solution obtained in step (2) was filtered, and the obtained precipitate was centrifuged and washed 3 times with a mixed solvent of water and acetone (the volume ratio...

Embodiment 3

[0057] A method for preparing an oxygen-vacancy-rich bismuth oxybromide ultra-thin nanosheet photochromic material, comprising the following steps:

[0058] (1) Dissolve 1.0g polyvinylpyrrolidone (average molecular weight 30000) and 1.0g mannitol in 30mL water, stir until the solution is transparent, add 0.353g bismuth sulfate, continue stirring until bismuth sulfate is completely dissolved, then add 5mL of 0.2mol / L sodium bromide aqueous solution, after stirring for 30 minutes, a mixed solution was obtained.

[0059] (2) The mixed solution in step (1) was transferred to a polytetrafluoroethylene reactor with a volume of 60 mL, reacted at 150° C. for 12 hours, and cooled naturally to room temperature after the reaction was completed.

[0060] (3) Filter the reaction solution obtained in step (2), centrifuge and wash the obtained precipitate three times with a mixed solvent of water and acetone (the volume ratio of water and acetone is 1:5), and dry at 80°C for 9 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com