Biomass-based thermosensitive bionic hydrogel adsorption material as well as preparation method and application thereof

An adsorption material and biomass technology, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problem of harmful compounds, etc., to achieve efficient removal, accelerated adsorption rate, high photothermal conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

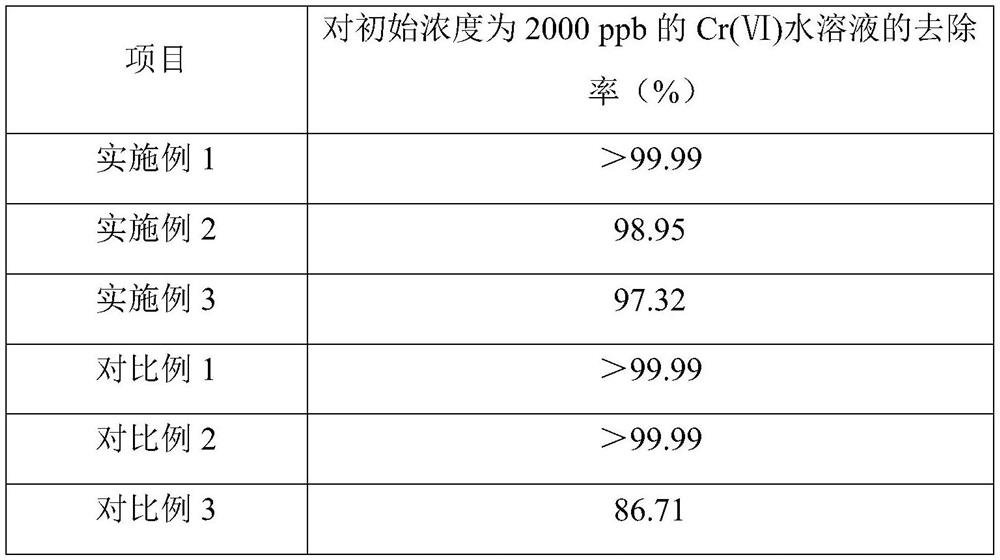

Embodiment 1

[0029] Example 1: Preparation of Biomass-Based Thermosensitive Biomimetic Hydrogel Adsorbent Material

[0030] (1) Slowly add polyethyleneimine to the N-isopropylacrylamide solution with a mass ratio of 50wt% polyethyleneimine aqueous solution with a mass average molecular weight of 70000 and N-isopropylacrylamide at a mass ratio of 1:3 , stirred evenly and reacted for 1 day, then frozen to terminate the reaction, and after 2 days of dialysis, freeze-dried. A dried 6.5 g sample of polyethyleneimine / N-isopropylacrylamide polymer was dissolved in 1.0 g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1.0 g N -Reaction with carboxylated nanocellulose under the action of hydroxysuccinimide catalyst, the carboxylated nanocellulose used is prepared from bagasse as raw material, carboxylated nanocellulose and polyethyleneimine / N-isopropyl The mass ratio of acrylamide polymer is 1:6.

[0031] (2) 12.0g of Tris and 3mL of dilute hydrochloric acid were uniformly mixed a...

Embodiment 2

[0033] Example 2: Preparation of Biomass-Based Thermosensitive Biomimetic Hydrogel Adsorbent Material

[0034](1) Slowly add polyethyleneimine to the N-isopropylacrylamide solution with a mass ratio of 50wt% polyethyleneimine aqueous solution with a mass average molecular weight of 70000 and N-isopropylacrylamide at a mass ratio of 1:2 , stirred evenly and reacted for 1 day, then frozen to terminate the reaction, and after 2 days of dialysis, freeze-dried. A dried 6.5 g sample of polyethyleneimine / N-isopropylacrylamide polymer was dissolved in 1.0 g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1.0 g N -Reaction with carboxylated nanocellulose under the action of hydroxysuccinimide catalyst, the carboxylated nanocellulose used is prepared from bagasse as raw material, carboxylated nanocellulose and polyethyleneimine / N-isopropyl The mass ratio of acrylamide polymer is 1:3.

[0035] (2) 12.0g of Tris and 3mL of dilute hydrochloric acid were uniformly mixed an...

Embodiment 3

[0037] Example 3: Preparation of Biomass-Based Thermosensitive Biomimetic Hydrogel Adsorbent Material

[0038] (1) Slowly add polyethyleneimine to the N-isopropylacrylamide solution with a mass ratio of 50wt% polyethyleneimine aqueous solution with a mass average molecular weight of 70000 and N-isopropylacrylamide at a mass ratio of 1:1 , stirred evenly and reacted for 1 day, then frozen to terminate the reaction, and after 2 days of dialysis, freeze-dried. A dried 6.5 g sample of polyethyleneimine / N-isopropylacrylamide polymer was dissolved in 1.0 g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1.0 g N -Reaction with carboxylated nanocellulose under the action of hydroxysuccinimide catalyst, the carboxylated nanocellulose used is prepared from bagasse as raw material, carboxylated nanocellulose and polyethyleneimine / N-isopropyl The mass ratio of acrylamide polymer is 1:5.

[0039] (2) 12.0g of Tris and 3mL of dilute hydrochloric acid were uniformly mixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com