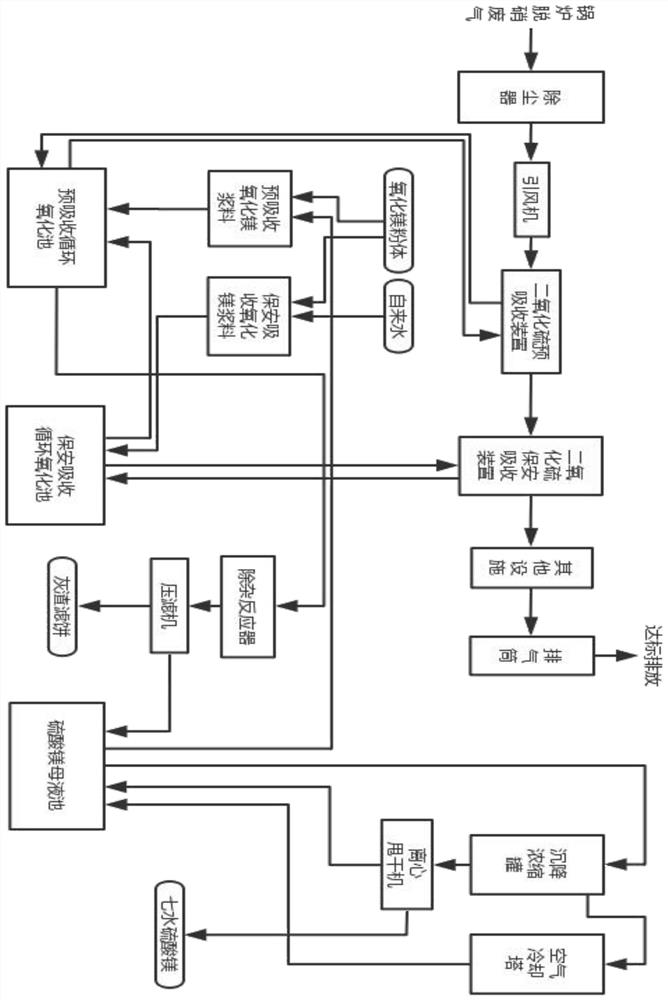

Ultralow-consumption crystallization and recovery method of magnesium sulfate from sulfur-containing waste gas through multistage combined desulfurization wastewater critical saturation method

A technology for desulfurization wastewater and magnesium sulfate, applied in the fields of magnesium sulfate, chemical instruments and methods, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Example: 2×65t / h boiler + 2×6MW back pressure turbogenerator desulfurization system transformation

[0064] 1. Basic situation of existing boilers

[0065] The existing two boilers share a 120 high exhaust pipe. The two boilers operate simultaneously during the heating period; only one operates during the non-heating period. The annual coal consumption is 95,000 tons. The annual operating hours of the boiler are 8760h, 3360h during the heating period and 5400h during the non-heating period. The annual power generation of the project is 62 million kWh, the annual power supply is 38.26 million kWh, and the annual heat supply is 2.2 million GJ. The sulfur dioxide desulfurization efficiency is not less than 99%, which can meet the 35mg / m3 in the "Emission Standard of Air Pollutants for Thermal Power Plants" (DB37 / 664-2019) 3 standard. The actual online monitoring data range before transformation is 5.5-22mg / m 3 ; The measured emission rate is 0.12~0.47kg / h. The measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com