Nickel matte high-pressure leaching gas recovery device

A high-pressure leaching and gas recovery technology, applied in gas treatment, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of limited adsorption capacity of activated carbon, insufficient absorption of sulfur dioxide, and easy to reach the adsorption limit. Adsorption, easy to fully clean, easy to reuse the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

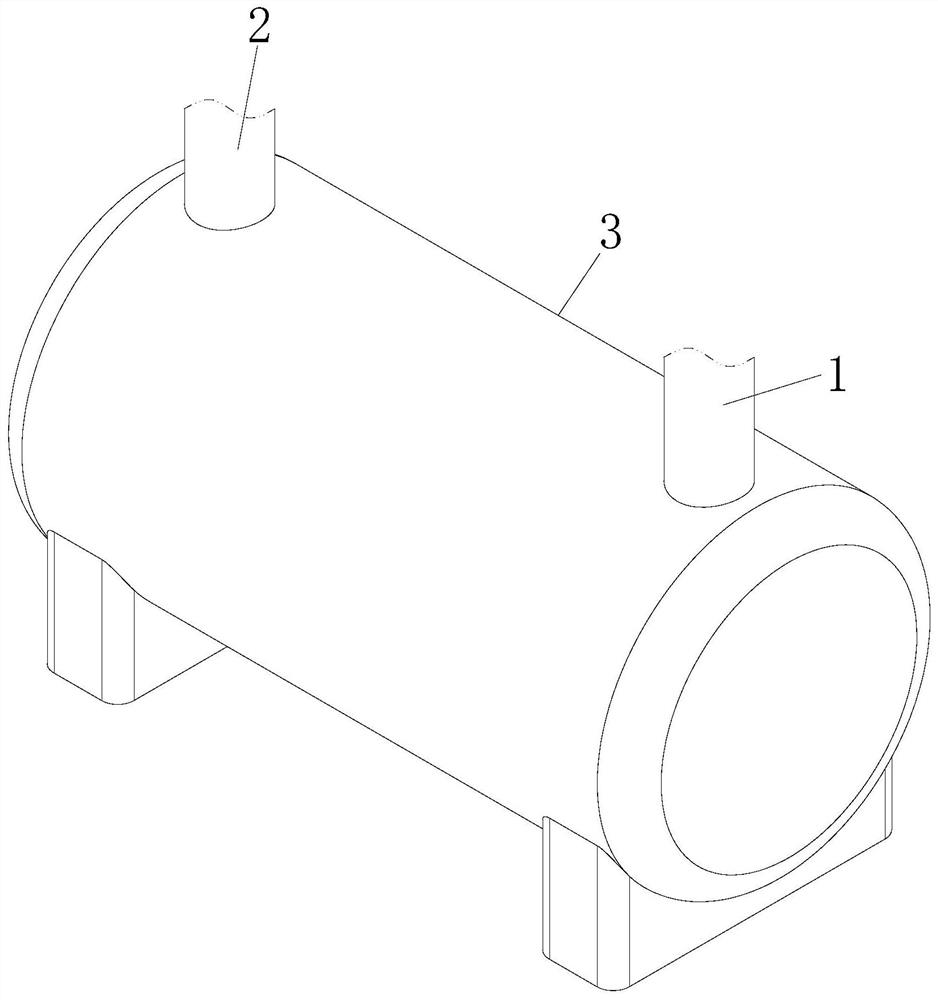

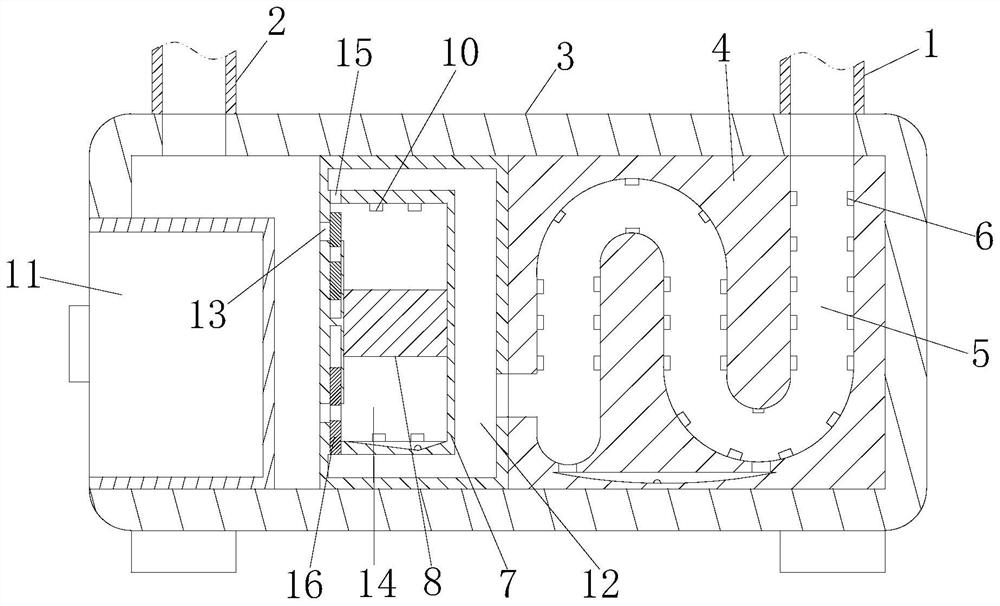

[0030] see Figure 1-5 As shown, a nickel matte high-pressure leaching gas recovery device includes an air inlet pipe 1, an air outlet pipe 2 and a tank body 3; the top of the tank body 3 is fixedly connected with an air inlet pipe 1 near the side end surface of the tank body 3; The top of the tank body 3 is fixedly connected with an air outlet pipe 2 near the other end surface of the tank body 3; the inside of the tank body 3 is fixedly connected with a guide block 4 at a position close to the air intake pipe 1; There is a curved channel 5; the inside of the curved channel 5 is fixedly connected with a uniformly arranged first spray head 6; the inside of the tank body 3 is fixedly connected with the installation block 7 at the side of the guide block 4; the installation block 7 The interior of the adsorption block 8 is provided with an adsorption block 8; the interior of the adsorption block 8 is provided with activated carbon 9; the interior of the installation block 7 is fi...

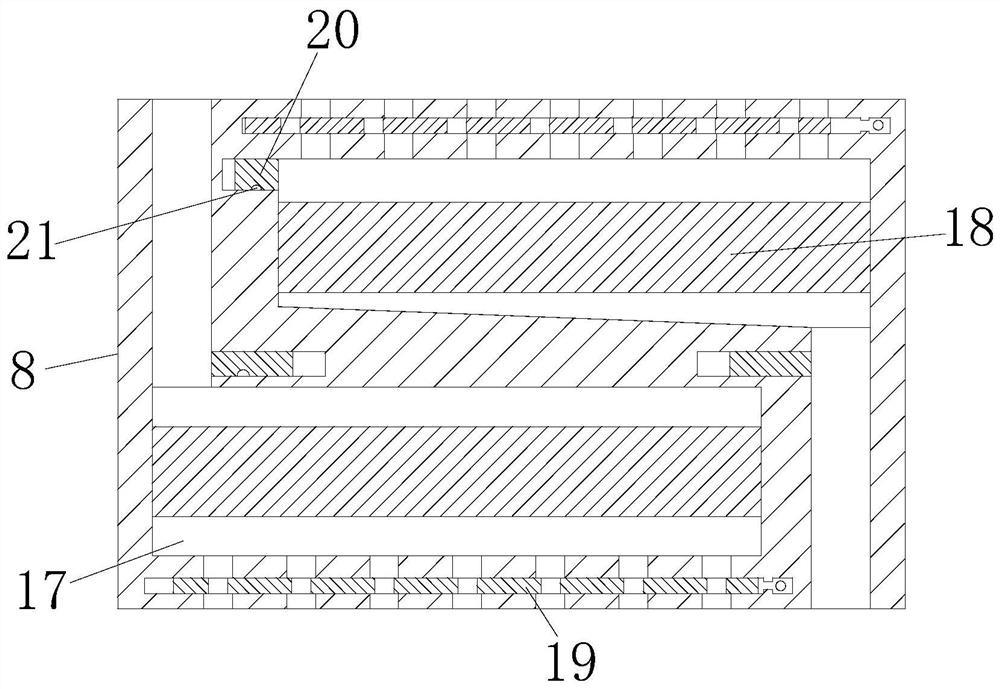

Embodiment 2

[0040] see Figure 6 As shown, elastic stay cords 32 are fixedly connected between the two corresponding adjustment blocks 23; elastic airbags 33 evenly arranged are fixedly attached to the surfaces of the elastic stay cords 32; during work, by setting the elastic stay cords 32. The surface of the elastic pull cord 32 is fixed to the evenly arranged elastic airbag 33. After the cleaning of the activated carbon 9 is completed, the adjustment block 23 needs to be slid and reset to make the filter screen 25 tightened. After the filter screen 25 has been used for a long time, Deformation easily occurs, and then the filter screen 25 after tension is still in a loose state, which will also make the activated carbon 9 inside the filter screen 25 not dense, and the absorption of sulfur dioxide will be insufficient. By controlling the expansion of the elastic airbag 33, the active carbon Carbon 9 is further pressurized to ensure the full absorption of sulfur dioxide in the later stage....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com