Ionic membrane method hydrochloric acid electrolysis device

A technology of ion membrane electrolyzer and ion membrane method, which is applied in the field of ion membrane method hydrochloric acid electrolysis device, and can solve the problems of low purity of chlorine gas and high energy consumption of electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

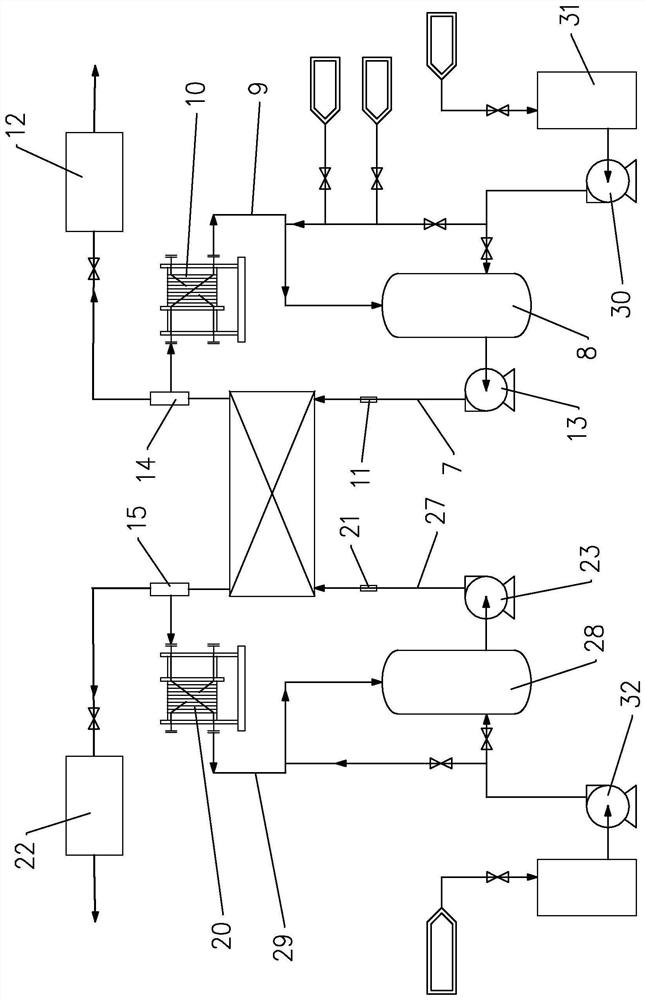

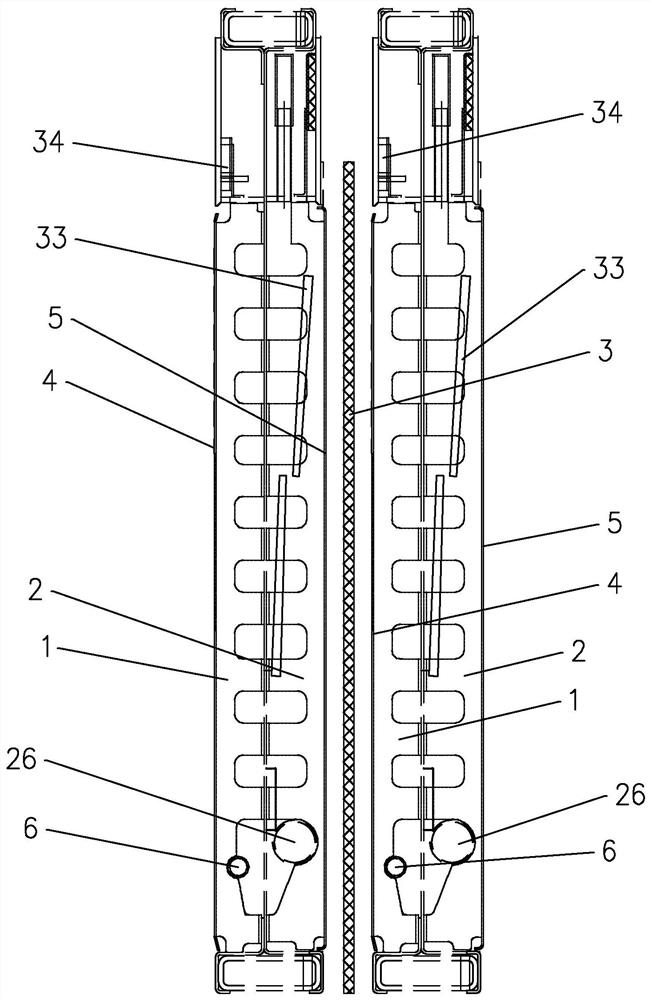

Method used

Image

Examples

Embodiment 1

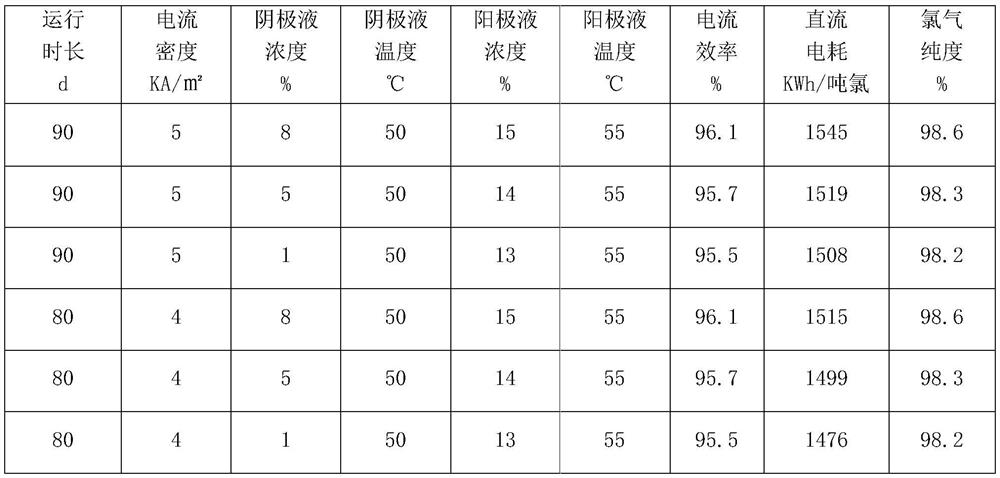

[0042] In this embodiment, the hydrochloric acid of the anolyte enters the tank at a temperature of 55°C and a concentration of 13%-15% after heat exchange; the hydrochloric acid of the catholyte enters the tank at a temperature of 50°C and a concentration of 1%-8% after heat exchange; the operating current density It is 4-5KA / ㎡. After 90 days of continuous operation, the following process data were obtained in Table 1:

[0043] Table 1

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com