Polyimide resin with self-healing function, polyimide film and preparation method, and flexible foldable display cover base film

A technology of polyimide resin and polyimide film, which is applied in the field of materials, can solve the problems of poor mechanical properties, limited self-repair times and efficiency, etc., and achieve stable process, simple operation and high light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

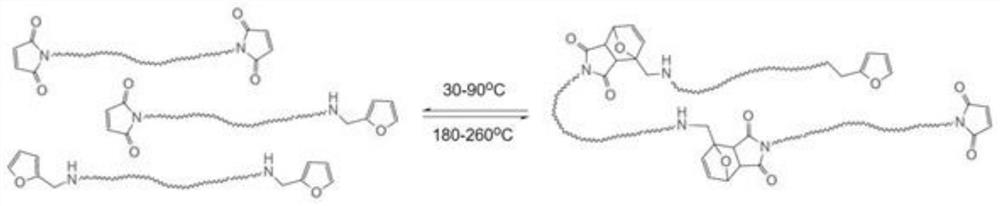

Method used

Image

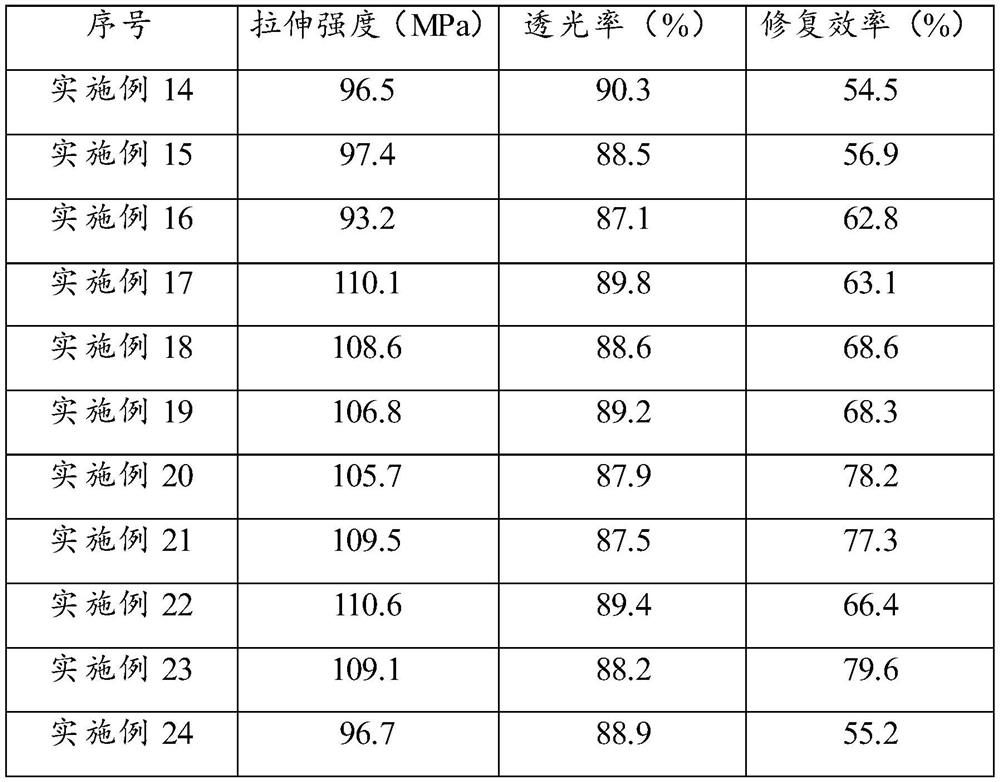

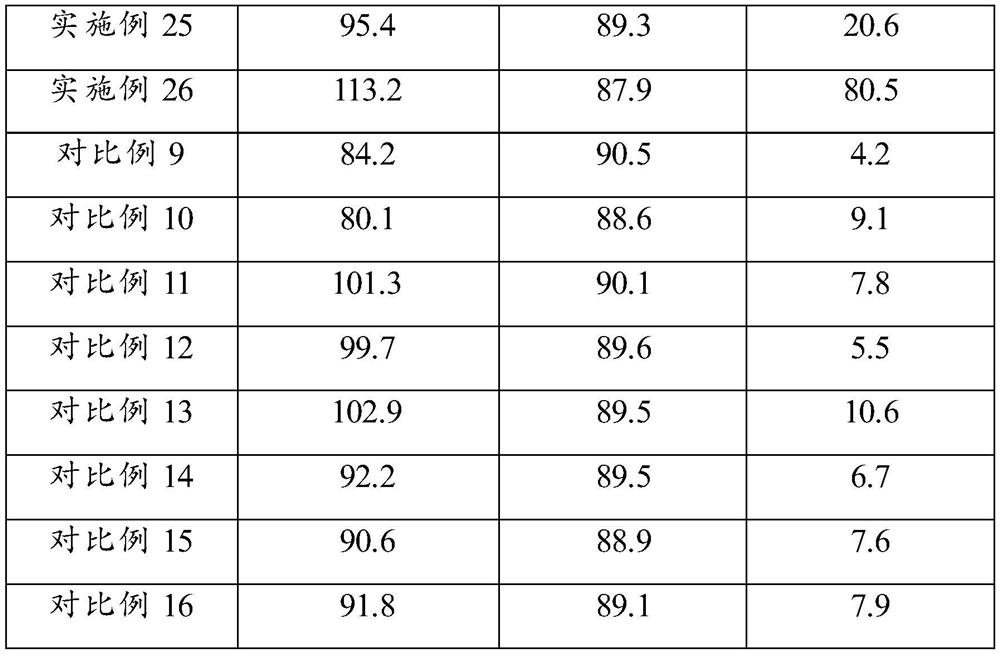

Examples

Embodiment approach

[0057] As an optional embodiment of the present invention, the diamine monomers include 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl, 1,4-bis(4-amino-2-tri Fluoromethylphenoxy)benzene, 9,9-bis(4-aminophenyl)fluorene, 2,2-bis[4-(4-aminophenoxy)phenyl]propane, 2,2-bis[ Any one or a combination of at least two of 4-(4-aminophenoxy)phenyl]hexafluoropropane or 4,4'-bis(3-aminophenoxy)diphenylsulfone.

[0058] As an optional embodiment of the present invention, the dianhydride monomer includes 4,4-hexafluoroisopropylphthalic anhydride, 1,2,3,4-cyclobutanetetracarboxylic dianhydride, 4,4 Any one or a combination of at least two of '-oxybisphthalic anhydride, biphenyltetracarboxylic dianhydride or bisphenol A diether dianhydride.

[0059] As an optional embodiment of the present invention, the dehydrating agent includes any one or a combination of at least two of acetic anhydride, propionic anhydride or butyric anhydride.

[0060] As an optional embodiment of the present invention, ...

Embodiment approach

[0093] As a preferred embodiment of the present invention, the preparation method of the polyimide film with self-healing function comprises the following steps:

[0094] Dissolving the polyimide resin in the second solvent, drying at 60-80°C for 20-40 minutes, at 120-150°C for 20-40 minutes and at 220-250°C for 40-60 minutes in a nitrogen atmosphere, to obtain Repair function polyimide film.

[0095] By further limiting the preparation method of the polyimide film, the second solvent can be completely volatilized.

[0096] According to the fifth aspect of the present invention, there is also provided a base film for a flexible and foldable display screen cover, which is made of the above-mentioned polyimide resin with self-repair function or the above-mentioned polyimide film with self-repair function .

[0097] In view of the advantages of the above-mentioned polyimide resin or polyimide film with self-healing function, the flexible foldable display cover base film that uses...

Embodiment 1

[0100] This embodiment provides a polyimide resin with self-healing function, which is mainly made of the following raw materials:

[0101] Diamine monomer, dianhydride monomer, furfurylamine, maleic anhydride, dehydrating agent and catalyst.

[0102] Among them, the diamine monomer is 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl, the dianhydride monomer is 4,4-hexafluoroisopropylphthalic anhydride, and the diamine The molar ratio of monomer and dianhydride monomer is 1:1, maleic anhydride accounts for 1% of the total molar amount of diamine monomer and dianhydride monomer, furfurylamine accounts for the total molar amount of diamine monomer and dianhydride monomer 1% of the amount, the dehydrating agent is acetic anhydride, and the catalyst is pyridine.

[0103] The preparation method of the above-mentioned polyimide resin with self-repairing function comprises the following steps:

[0104] (a) Dissolve 16.01 g (50 mmol) of 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl in 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com