Method for organically modifying nano silicon dioxide aerogel

A nano-silica and aerogel technology, applied in the field of airgel, can solve the problems of limiting the practical application of nano-silica aerogel, poor compatibility of polyester thermal insulation and flame-retardant material matrix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare the modifier:

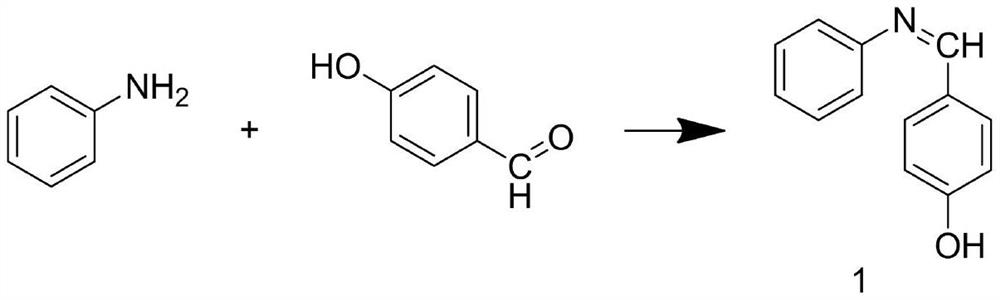

[0028] Step S11, mix aniline, p-hydroxybenzaldehyde and 1,4-dioxane, raise the temperature to 85°C under nitrogen protection, and react for 6 hours. After the reaction, carry out post-treatment. The post-treatment process is as follows: The reaction solution was cooled to room temperature, concentrated under reduced pressure to remove the solvent, and then washed with ethanol. After the washing was completed, it was dried to a constant weight at a temperature of 75° C. to obtain intermediate 1;

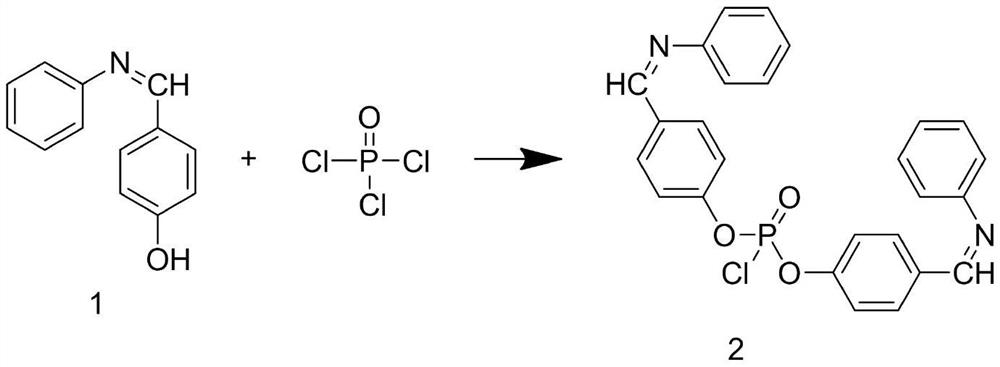

[0029] Step S12, mixing intermediate 1, tetrahydrofuran and triethylamine, adding phosphorus oxychloride dropwise at a temperature of 20°C, keeping the temperature constant after the addition, stirring for 10 hours, and post-processing after the reaction. The process of treatment is: concentrating the obtained reaction solution under reduced pressure to remove the solvent, and purifying through a column to obtain intermediate 2;

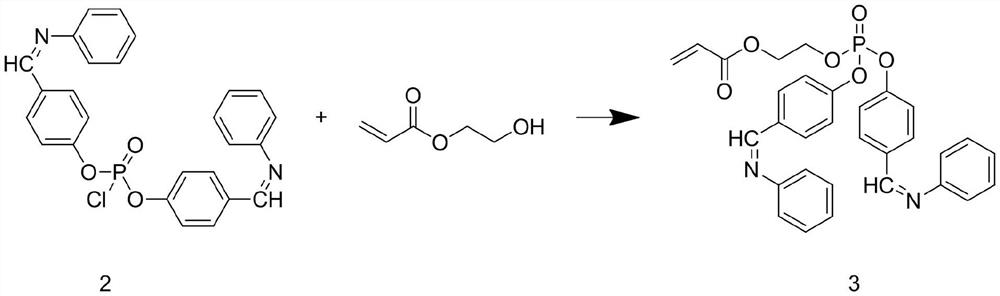

[0030] Step S13, mix 2...

Embodiment 2

[0034] Prepare the modifier:

[0035] Step S11, mix aniline, p-hydroxybenzaldehyde and 1,4-dioxane, raise the temperature to 85°C under nitrogen protection, and react for 6 hours. After the reaction, carry out post-treatment. The post-treatment process is as follows: The reaction solution was cooled to room temperature, concentrated under reduced pressure to remove the solvent, and then washed with ethanol. After the washing was completed, it was dried to a constant weight at a temperature of 75° C. to obtain intermediate 1;

[0036] Step S12, mixing intermediate 1, tetrahydrofuran and triethylamine, adding phosphorus oxychloride dropwise at a temperature of 25°C, keeping the temperature constant after the addition, stirring for 10 hours, and post-processing after the reaction. The process of treatment is: concentrating the obtained reaction solution under reduced pressure to remove the solvent, and purifying through a column to obtain intermediate 2;

[0037] Step S13, mix 2...

Embodiment 3

[0041] Preparation of organically modified nano-silica airgel:

[0042] After mixing tetraethyl orthosilicate, modifier and ethanol, add oxalic acid aqueous solution, stir magnetically for 30 minutes, and let it stand at room temperature for 24 hours; then add ammonia water drop by drop, stir for 30 minutes, and age at room temperature for 2 days to obtain a gel body; then the gel body is dried, and the graded drying method is used to dry at 60°C, 80°C, 100°C and 120°C for 24h, 2h, 1.5h and 1h; to obtain organically modified nano-silica airgel;

[0043] Among them, the concentration of oxalic acid aqueous solution is 1mol / L; the mass fraction of ammonia water is 25%; the mass ratio of ethyl orthosilicate and modifier is 1:0.5; The dosage ratio is 1g: 20mL: 0.6g: 0.5g; the modifier is prepared in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com