Preparation method of high-performance polytetrafluoroethylene copper-clad plate

A polytetrafluoroethylene and copper clad laminate technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as high cost, cost profit margin compression, and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

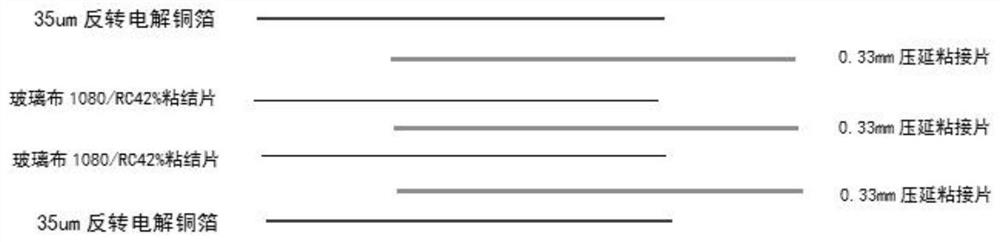

[0040] Use electronic-grade glass fiber cloth 1080 through a vertical gluing machine and two rubber basins to glue PTFE concentrate, the gluing line speed is 5.5m / min, low temperature 180 ℃ drying, 240 ℃ baking, high temperature 330 ℃ Sintering, automatic tension mode, the squeegee is controlled by the squeegee rod device to obtain the cloth type 1080 (RC42%) PTFE glass cloth-based adhesive sheet;

[0041] Use polytetrafluoroethylene dispersed resin powder to extrude and calender, then bake at 180°C for 5 minutes to obtain pure polytetrafluoroethylene adhesive film, with a width of 47cm and a thickness of 0.33mm;

[0042] A 0.762mm copper-clad laminate with a dielectric constant of 2.10 and a thickness of 0.762mm is prepared by using a glass cloth-based 1080 adhesive sheet with a weight ratio of 15% and a calendered adhesive film material with a weight ratio of 85% to cover both sides with a 35um inverted electrolytic copper foil.figure 1 shown in the structure;

[0043] The a...

Embodiment 2

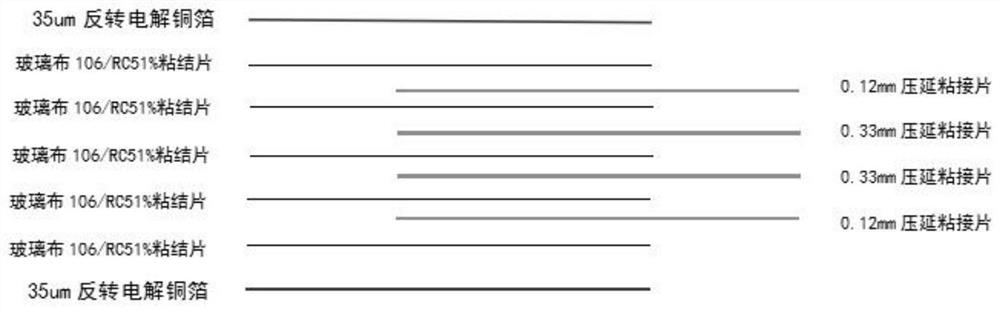

[0045] Use electronic-grade glass fiber cloth 106 to glue PTFE concentrate through a vertical gluing machine and two rubber basins. The gluing line speed is 6.0m / min. Dry at low temperature at 180°C, bake at 240°C, and high temperature at 330°C Sintering, automatic tension mode, the squeegee is controlled by the squeegee rod device to obtain the cloth type 106 (RC51%) PTFE glass cloth-based adhesive sheet;

[0046] Use polytetrafluoroethylene dispersed resin powder to extrude and calender, then bake at 180°C for 5-7 minutes to obtain pure polytetrafluoroethylene adhesive film, with a width of 47cm and a thickness of 0.12mm and 0.33mm;

[0047] A copper clad laminate with a dielectric constant of 2.20 and a thickness of 0.762mm is prepared by using a combination of glass cloth base 106 bonding sheet with a weight ratio of 18% and a calendered adhesive film material with a weight ratio of 82%. figure 2 shown in the structure;

[0048] The above proportions use a hydraulic high...

Embodiment 3

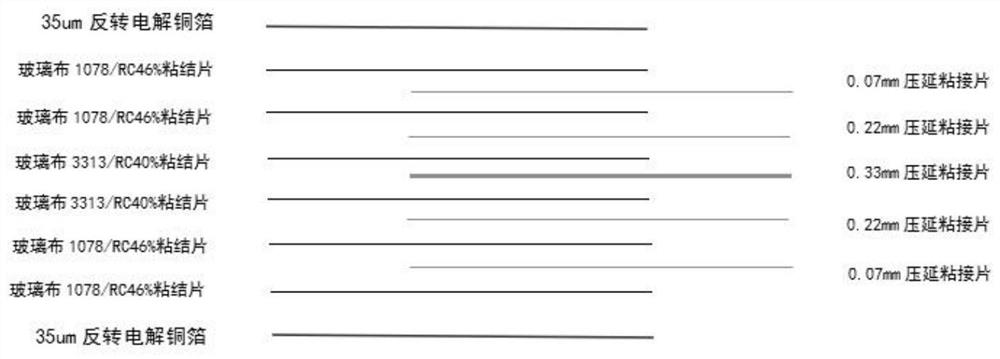

[0050] Use electronic grade glass fiber cloth 1078, 3313 to glue PTFE concentrate through vertical glue machine and two rubber basins, glue line speed is 5.2, 5.0m / min, dry at low temperature 180°C, bake at 240°C , Sintering at a high temperature of 335°C, automatic tension mode, controlling the squeegee through the squeegee rod device to obtain fabric types 1078 (RC46%), 3313 (RC40%) PTFE glass cloth-based adhesive sheets;

[0051] Use polytetrafluoroethylene dispersed resin powder to extrude and calender, then bake at 180°C for 5-7 minutes to obtain pure polytetrafluoroethylene adhesive film, with a width of 47cm and a thickness of 0.07mm, 0.22mm, and 0.33mm;

[0052] The dielectric constant is 2.55 and the thickness is 0.762, which is prepared by using glass cloth base 1078 bonding sheet with a weight ratio of 13%, 3313 bonding sheet with a weight ratio of 15%, and a calendered adhesive film with a weight ratio of 72%. mm copper clad laminate, match as follows image 3 sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com