Direct pulverzing mill of glass fiber reinforced plastic wastes

A waste and grinding machine technology, which is applied in grain processing, food science, smoke removal, etc., can solve the problem of high cost, achieve long service life and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further illustrated below in conjunction with the accompanying drawings and preferred embodiments.

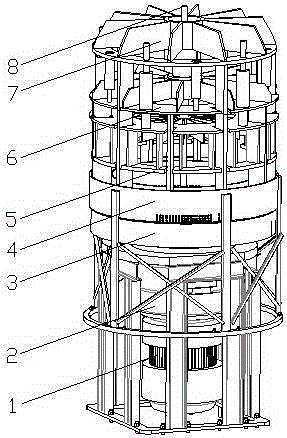

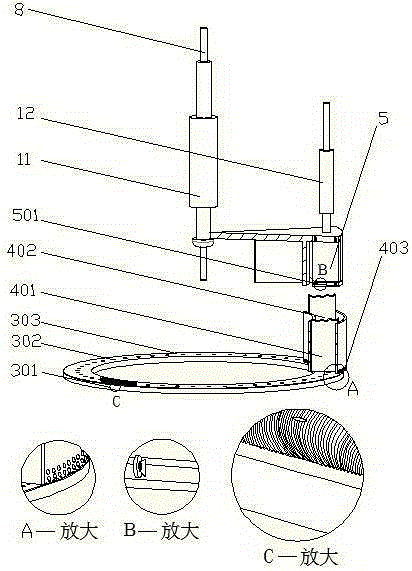

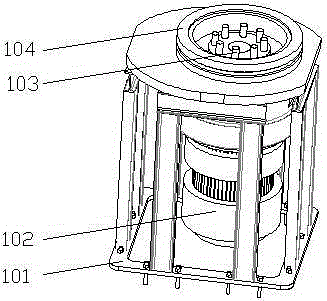

[0039] Such as figure 1 and 2 As shown, the FRP waste direct grinding machine includes a main motor 1 installed in a frame 7, a reducer 2, a grinding disc 3, a clamping frame 4, a pressure head 5, a fast forward / return disc 6, and a main motor 1 Connect the reducer 2, the main motor 1 and the reducer 2 are installed on the lower part of the frame 7, the reducer 2 drives the grinding disc 3, the grinding disc 303 is installed in the grinding disc 3, the clamping frame 4 is above the grinding disc 301, and the clamping frame 4 is composed of The pressure head guide plate 401 and two annular cylinders are welded together to form a clamping cavity 402, and a powder leakage hole I403 is set on the side wall of the clamping frame 4, and the pressure head 5 is installed on the clamping frame 4, fast forward\backward The disk 6 drives the indenter 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com