A bioactive degradable magnesium alloy guided bone regeneration membrane and its dense hole processing method

A technology that guides bone regeneration and bioactivity. It is applied in metal processing equipment, tissue regeneration, and manufacturing tools. It can solve problems such as lack of density distribution, increased processing difficulty, and unfavorable bone defect repair, so as to improve the treatment effect. The hole circumference is smooth and the hole quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

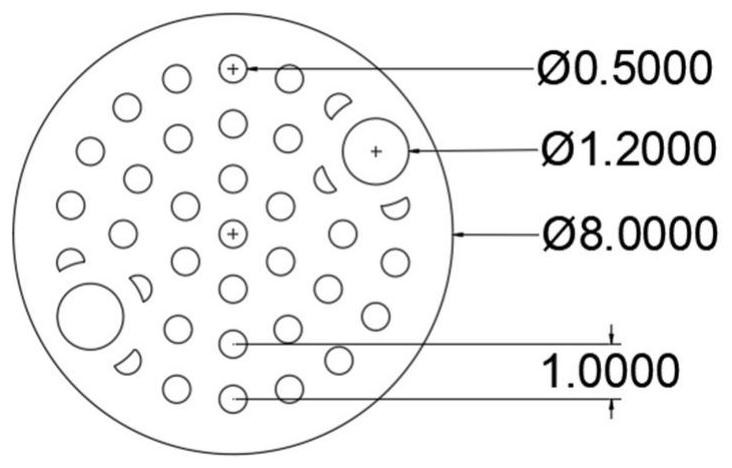

[0031] In order to facilitate the pre-experiment in rats and evaluate the effect of the barrier membrane on soft tissue ingrowth and the degree of degradation, the barrier membrane model was simplified as a disc with a diameter of 8 mm and a thickness of 0.08-0.30 mm with a through-hole area. The dense holes are all distributed in a circular area with a standard diameter of 0.5mm, and the diameter of the dense holes is 0.2mm. The distribution of the dense holes is as follows: image 3 Shown (unit: mm). Dense hole specifications and distribution rules can be directly used for figure 1 oral barrier membranes.

Embodiment 2

[0033] Others are identical with embodiment 1, and difference is that the diameter of dense hole is 0.1mm, and the distribution of dense hole is as follows Figure 4 Shown (unit: mm)

Embodiment 3

[0035] Others are identical with embodiment 1, and difference is that the diameter of dense hole is 0.05mm, and the distribution of dense hole is as follows Figure 5 Shown (unit: mm)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com