Industrialized morchella esculenta cultivation method and device

A morel cultivation and cultivation device technology, which is applied in the fields of industrial morel cultivation method and its cultivation device, edible fungus industrial management, cultivation mode and industrial management, and can solve the problems of long cycle, low output and technical process. unclear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

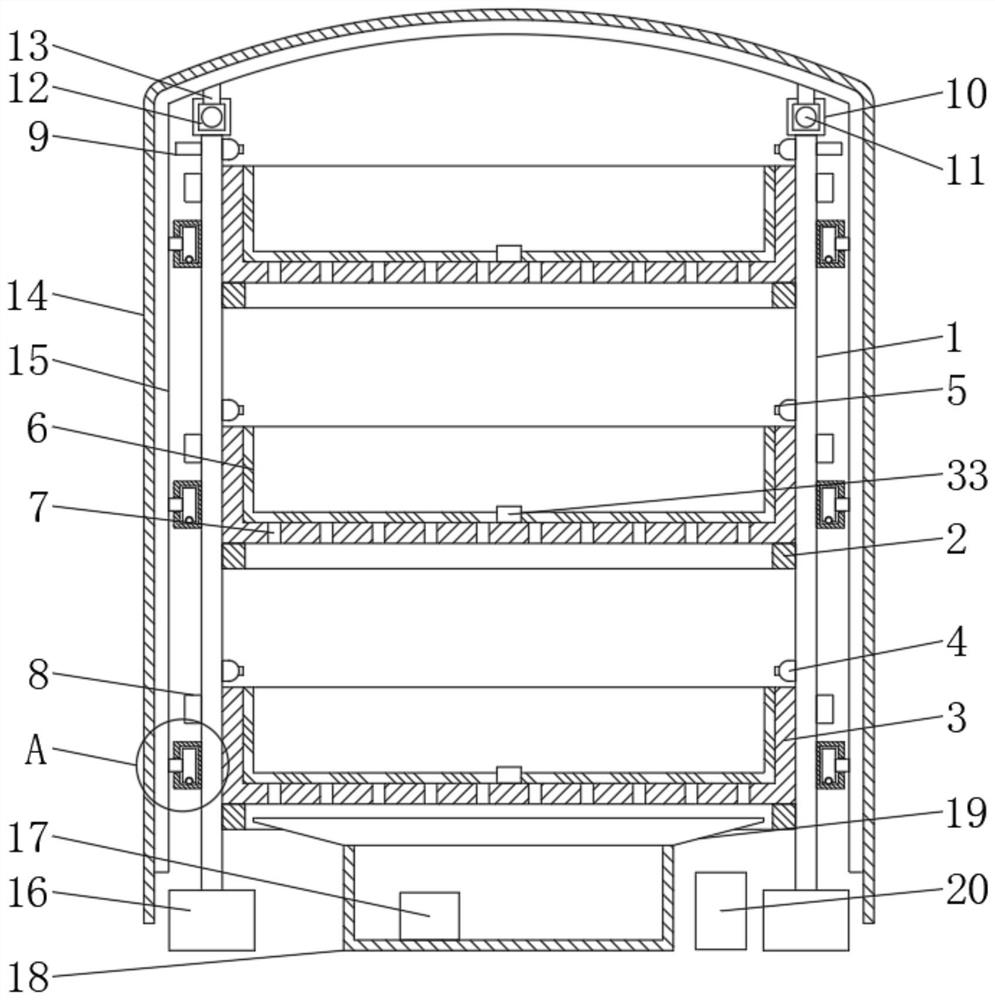

Embodiment 1

[0047] 1. Cultivated matrix pretreatment and upper shelves: According to the Soil testing standards, the cultivation matrix components were measured, 70% soil, 18% humus, 10% perlite, 1% landciniform, 1% lime mix Uniform, even after 20 days, even in the cultivation pool, the thickness is 25 cm.

[0048] 2. Sowing: Morchella Sextelata, which is ready to be prepared in advance, spread on the bed, the mushroom temperature is 18 ° C, the air humidity is 95%, carbon dioxide concentration 1800 ppm, avoid Light culture for 2 days.

[0049] 3. Add aseptic nutrient matrix: 2 days of regular seeding, add high pressure or normal pressure of high pressure or normal pressure (preferred formula: 40% grain, 30% sorghum, 28% corn core, 1% of gypsum, light The calcium carbonate is 1%, the water content of 53%, and the acid is 5 kg (about 15 * 28 cm is 10 bags), and it is immediately hooded, and the water is placed after 3 days.

[0050] 4. Filament culture: After adding aseptic nutrient matrix, co...

Embodiment 2

[0056] 1. Cultivated matrix pretreatment and upper shelves: According to GB / T32737-2016 soil testing standards, the cultivation matrix components were measured, 60% soil, 18% humic, 20% perlite, 1% landcass, 1% lime mix Uniform, even after 15 days, even in the cultivation pool, the thickness is 30 cm.

[0057] 2. Sowing: Morchella Importuna cultivation, Morchella Importuna, in advance, spread on a cultivated substrate per square meter, a mushroom temperature 18 ° C, air humidity 95%, carbon dioxide concentration 800 ppm Anti-lighting for 3 days.

[0058] 3. Add aseptic nutrition matrix: After 3 days of regular seeding, add high pressure or normal sterilization of high pressure or normal sterilization (preferred formula: 40% grain, 30% sorghum, 28% corn core, 1% of gypsum, light The calcium carbonate is 1%, the water content of 53%, and the acid is nature is 10 kg (approximately 15 * 28 cm), and the water is hooded immediately, and the water is poured after 3 days.

[0059] 4. Fi...

Embodiment 3

[0065] 1. Cultivation matrix pretreatment and upper shelves: According to GB / T32737-2016 soil testing standards, the cultivation matrix ingredients were measured, and 80% soil, 8% humic, 10% perlite, 1% landcass, 1% lime mix Uniform, even after 20 days, even in the cultivation pool, the thickness is 25 cm.

[0066] 2. Sowing: Morchella Eximia cultivated seeds in advance, spread on the bed, 23 ° C per square meter, 23 ° C in the mushroom temperature, 95% air humidity, 1800 ppm of carbon dioxide, Culture for 1 day.

[0067] 3. Add aseptic nutritional matrix: After 1 day of regular seeding, add high pressure or normal sterilization of high voltage or normal pressure (preferable: 30% grain, 3% sorghum, 28% corn core, 1% of gypsum, light The calcium carbonate is 1%, the water content of 53%, and the acid is nature is 10 kg (approximately 15 * 28 cm), and the water is hooded immediately, and the water is poured after 3 days.

[0068] 4. Filament culture: After adding aseptic nutrient ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com