Water-cooled parallel flow heat exchanger with rows of flat pipes

A parallel flow heat exchanger, water-cooled technology, applied in the direction of heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problem of reducing the windward area of the heat exchanger, affecting the performance of the device, and inconvenient disassembly and replacement, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

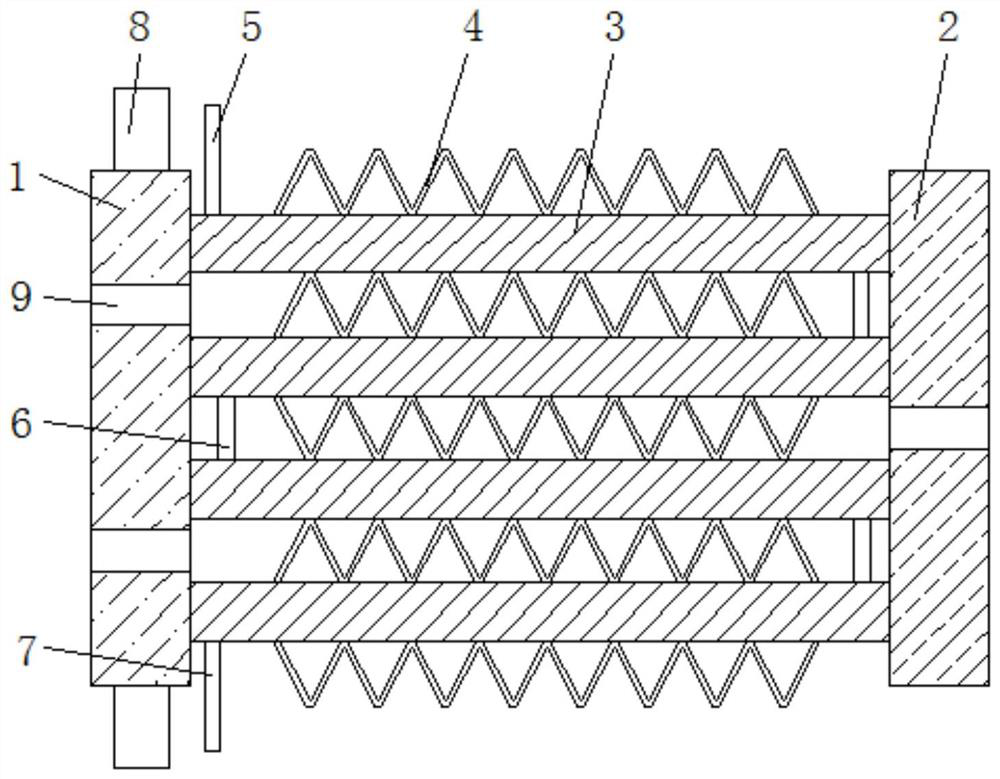

[0042] see Figure 1 to Figure 8 , the present invention provides a technical solution of a water-cooled parallel flow heat exchanger connected with flat tubes: a water-cooled parallel flow heat exchanger connected with flat tubes, including a first header 1 and a 1 side of the second header 2, a number of flat tubes 3 are arranged between the first header 1 and the second header 2, and a number of cooling fins are fixedly installed on the upper and lower end surfaces of the plurality of flat tubes 3 sheet 4, the shape of several heat dissipation fins 4 is triangular, and the heat dissipation fins 4 on both sides of the flat tube 3 are staggered;

[0043] The upper end surface of the first collecting pipe 1 is fixedly equipped with a water inlet pipe 8, and the lower end surface of the first collecting pipe 1 is fixedly installed with a water outlet pipe 16. Both the water inlet pipe 8 and the water outlet pipe 16 are L-shaped, and the water inlet pipe 8 is plugged. Inside th...

Embodiment 2

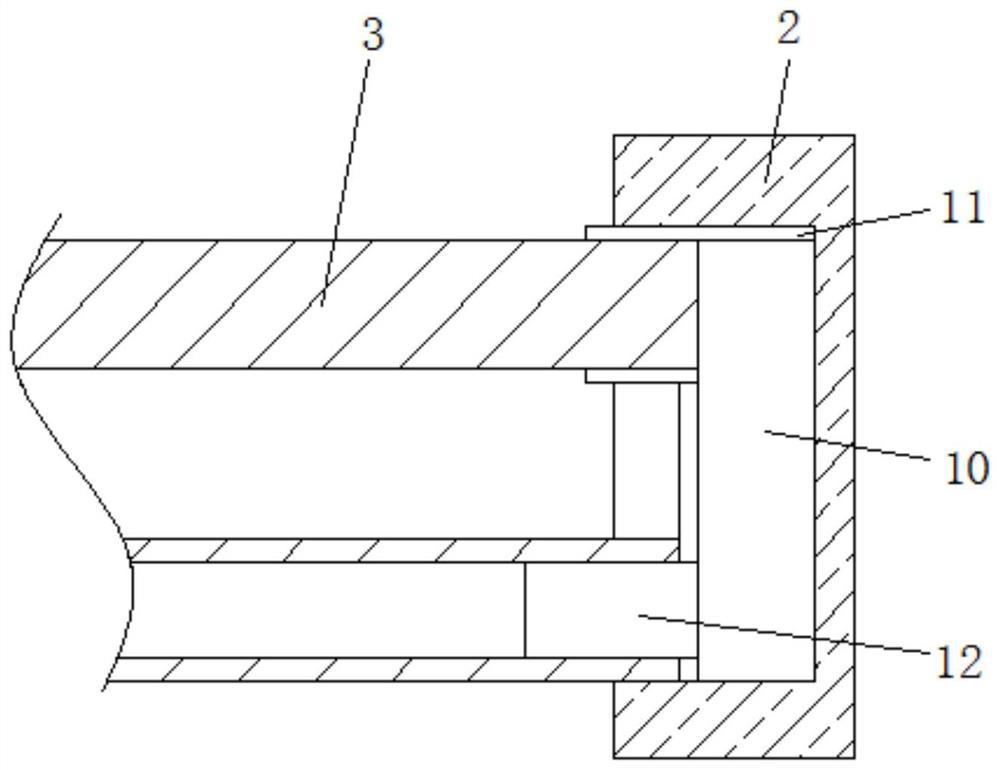

[0052] Such as figure 2 , Figure 4 and Figure 7 As shown, under the situation that other parts are all identical with embodiment 1, the difference between this embodiment and embodiment 1 is:

[0053] The side of the second header 2 is provided with an installation groove 15, and the inside of the installation groove 15 is fixedly installed with a ventilation pipe 10, and the side of the ventilation pipe 10 is fixedly installed with a sleeve pipe 11 and an intubation pipe 12, and the insertion pipe 12 is located at the side of the sleeve pipe 11. Below, and the cross-sectional area of the intubation tube 12 is smaller than the cross-sectional area of the sleeve tube 11, one end of the flat tube 3 is inserted into the inside of the sleeve tube 11, and the other end of the flat tube 3 is sleeved on the intubation tube 12, and the flat tube The end surface of 3 is installed on the corresponding intubation tube 12 or casing 11, so that the flat tube 3 and the correspondin...

Embodiment 3

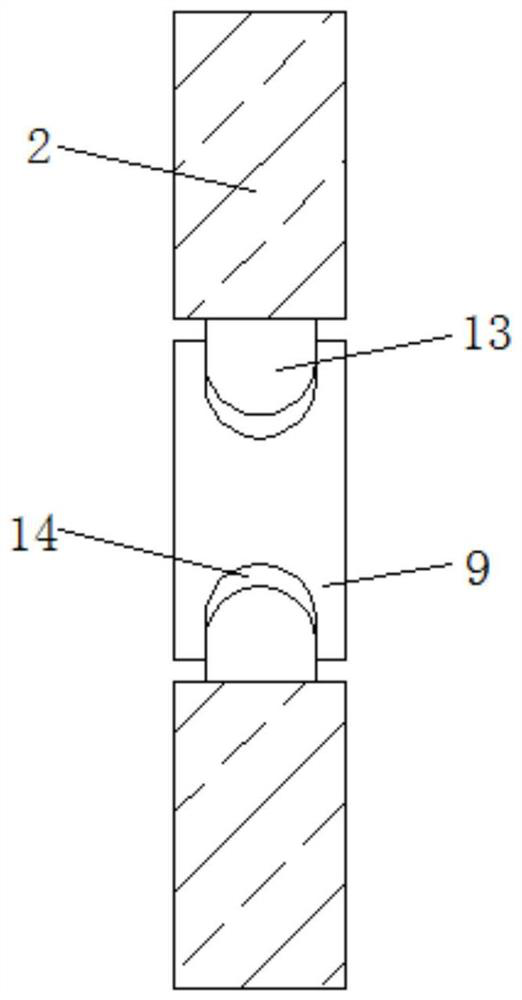

[0057] Such as figure 2 , image 3 and Figure 8 As shown, under the situation that other parts are all identical with embodiment 1, the difference between this embodiment and embodiment 1 is:

[0058] Both ends of the flat tube 3 are provided with a positioning mechanism, the positioning mechanism includes a guide plate 24, the inside of the guide plate 24 is provided with a chute 25, the inside of the chute 25 is slidingly installed with a slide plate 26, and the side of the slide plate 26 is fixedly installed with an extension rod 27. The other end surface of the extension rod 27 is fixedly equipped with a baffle plate 28, and several springs 29 are fixedly installed between the baffle plate 28 and the flat tube 3. The outer surfaces of the baffle plate 28 are all inclined surfaces, which can be convenient for users to It is in contact with the corresponding intubation tube 12 or sleeve tube 11, and the side of the baffle plate 28 far away from the guide plate 24 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com