Large heat input welding 670MPa-grade steel plate and manufacturing method thereof

A large heat input welding and manufacturing method technology, applied in the field of steel and its manufacturing, can solve the problems of poor strength and toughness, welding cold cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

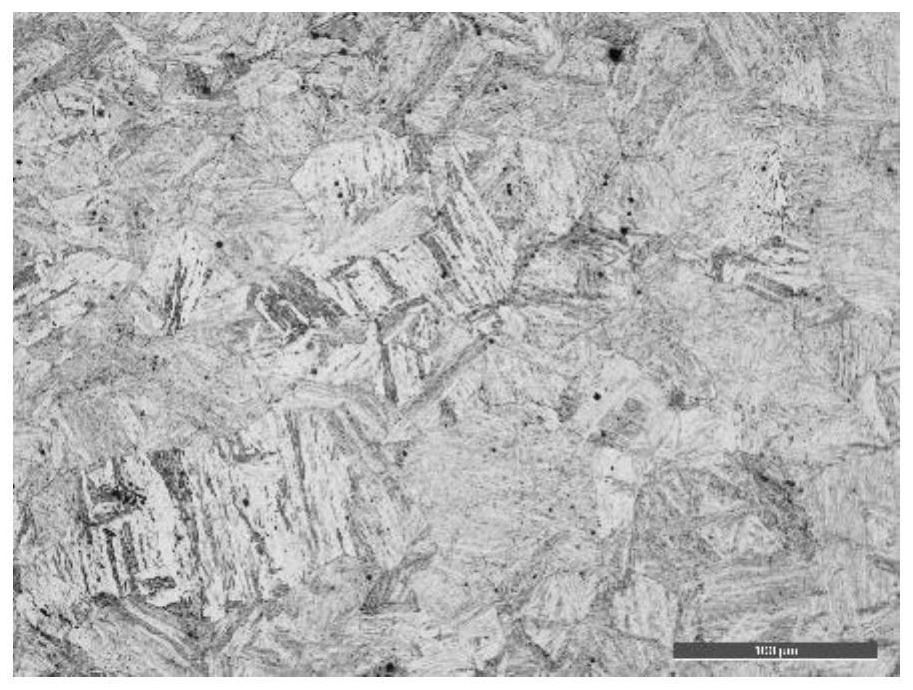

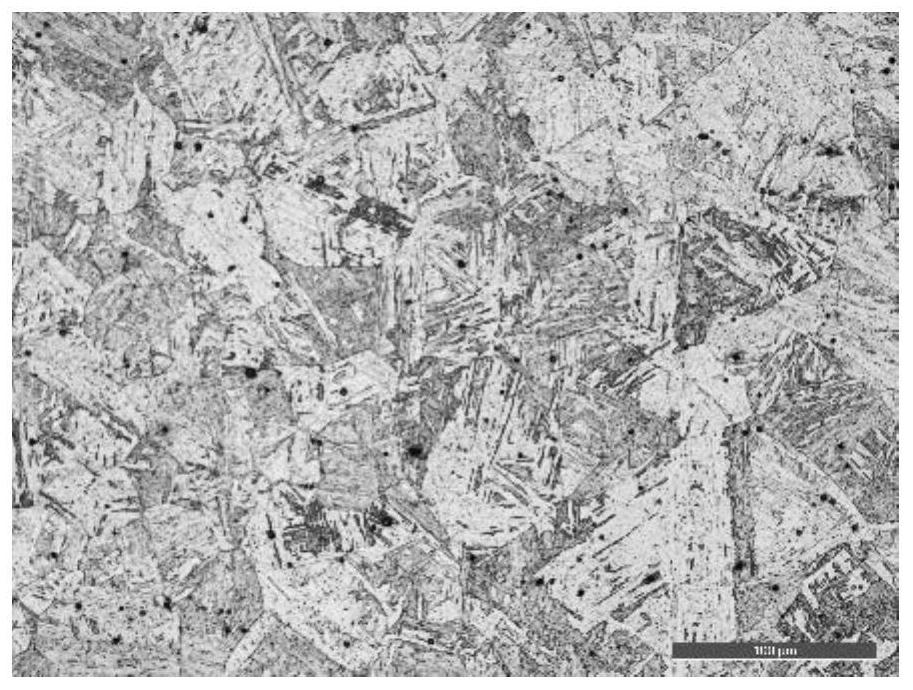

Image

Examples

Embodiment 1-6 and comparative example 1-4

[0047] The large heat input welding 670MPa grade steel plate of the present invention adopts the following steps to make:

[0048] (1) Smelting and casting;

[0049] (2) Rolling: heating the slab to 1050-1250°C for rolling, controlling the final rolling temperature to 900-1100°C, and cooling to below 400°C after rolling;

[0050] (3) Quenching + tempering heat treatment: the quenching heating temperature is 900-980°C, and then water quenching; the tempering heating temperature is 600-700°C.

[0051] The chemical composition and related process parameters of Examples 1-6 all meet the control requirements of the design specification of the present invention. Correspondingly, in Comparative Examples 1-4, the control arrangements have chemical components or related process parameters that fail to meet the design requirements of the invention.

[0052] Table 1 lists the mass percentage distribution of each chemical element in the high heat input welded 670MPa grade steel plates o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com