Ultraviolet-activated two-component super-hydrophobic polyurethane winding adhesive

A two-component polyurethane and polyurethane prepolymer technology, applied in the field of ring rubber, can solve the problems of poor uniformity, high viscosity, and inability to eliminate the ring rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] UV-activated two-component polyurethane winding ring gum, including two components of AB,

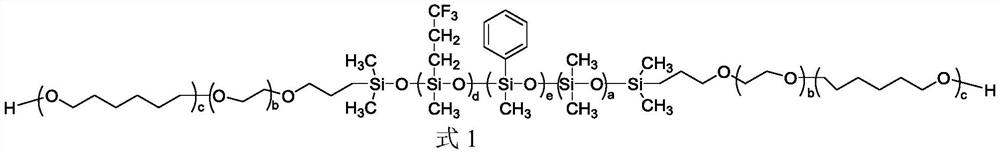

[0049] Among them, the A component is a hydrophobic polyurethane prepolymer, and the preparation method is as follows: 205.055 g of 1H, 1H, 11H, 11H-全 全-3,6,9-trioxide-1,11-diol (0.5 Mol), 733.5 g of hydroxypropyl blocking organic fluorine modified siloxane (SF-001) (0.5 mol) was added to 80-90 ° C in a stirred reactor, maintaining vacuum 0.09 MPa-0.1 MPa in agitation In the state of vacuum dehydration for 3 hours, then 50 ° C or less, 4448 g of osteol diisocyanate (IPDI) (2 mol) was added to maintain 80-83 ° C for 3 h, and after the hydroxyl group reaction, the reaction was completed. The hydrophobic polyurethane prepolymer S-1, NCO equivalent is 691.5, and the NCO content is 6.073%.

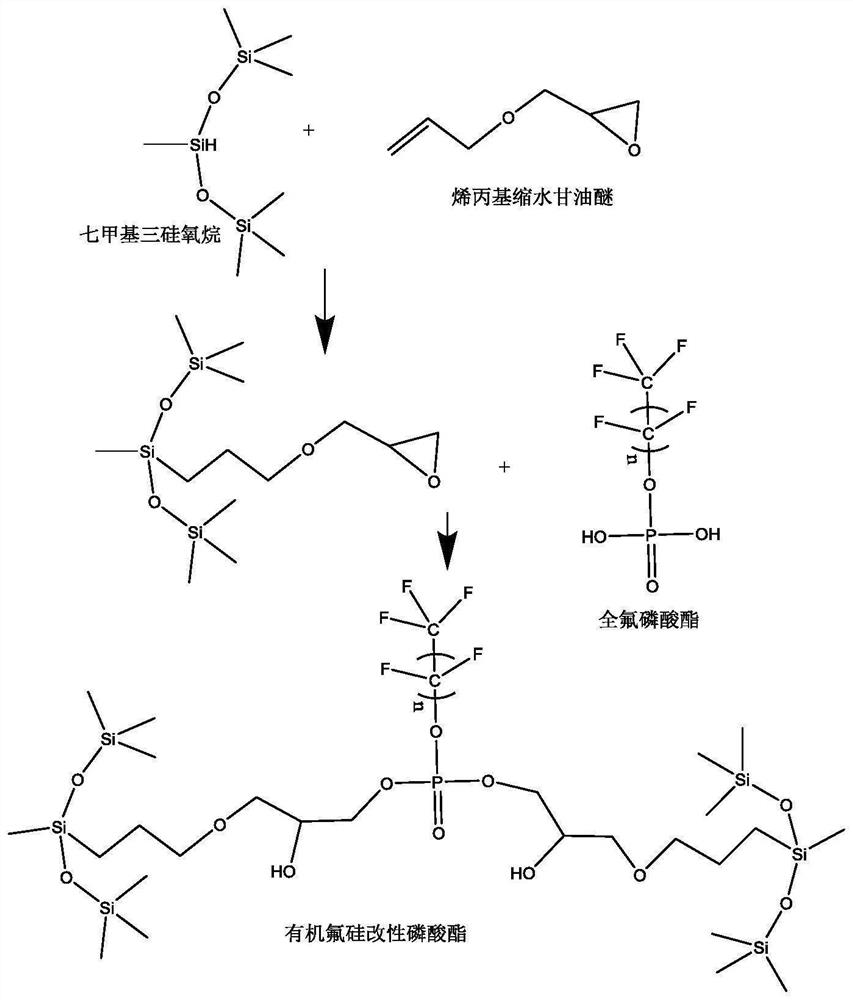

[0050] The B component is mixed by the following components by mass: the hydroxypropylene seal organic fluorochemical silicone (SF- 001) 92%, organic fluorine modified phosphate FGP-1 5%, light produc...

Embodiment 2

[0053] UV-activated two-component polyurethane winding ring gum, including two components of AB,

[0054] Among them, the A component is a hydrophobic polyurethane prepolymer, and the preparation method is as follows: 1467 g of hydroxypropyl-blocking organic fluorochemical modified siloxane (SF-001) (1 mol) is added to 90-95 At ° C, the vacuum degree of 0.09 MPa-0.1 MPa was removed in the stirred state for 3 hours, then the temperature was lowered to 60 ° C or lower, and 524.6 g of 4,4-diisocyanate chironylmethane (HMDI) (2 mol) was maintained after 85- The reaction was reacted at 88 ° C for 4 h, and after the hydroxyl group reaction was complete, the reaction was completed to obtain the hydrophobic polyurethane prepolymer S-2, NCO equivalent was 995.8, and the NCO content was 4.22%.

[0055] The B component is mixed by the following components by mass: hydroxypropylene sealing organic fluorochemical silicone (SF- 001) 58.5%, polycaprolactone-modified organic fluorine-modified phe...

Embodiment 3

[0058] UV-activated two-component polyurethane winding ring gum, including two components of AB,

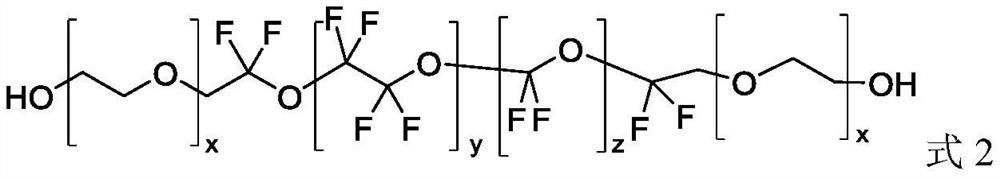

[0059] Among them, the A component is a hydrophobic polyurethane prepolymer, and the preparation method is as follows: 1450 g of polycaprolactone modified organic fluorine-modified phenylsiloxane (SF-002) (0.5 mol) is added to the stirred reactor Heat until 95-100 ° C, maintaining vacuum 0.09 MPa-0.1 MPa in a state of vacuum dehydration for 3 hours, then cooled to 60 ° C or less, and then maintained 75 after the addition of 168.19 g of hexamethylene diisocyanate (HDI) (1 mol) -80 ° C reaction for 6 h, after the hydroxyl group reaction was complete, the reaction was completed, and the hydrophobic polyurethane prepolymer S-3, NCO equivalent was 1618.19, and the NCO content was 2.59%.

[0060] The B component is mixed by the following components by mass: hydroxypropylene seal organic fluorochemical silicone (SF- 001) 67.3%, 1H, 1H, 11H, 11H-全 -3, 6, 9-trioxide-1, 11-diol 25%, organic fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com