Large 3D printing device based on granule screw extruder and working method of large 3D printing device

A screw extruder and 3D printing technology, applied in the field of 3D printing, can solve the problems of limiting the forming efficiency of large-scale additive manufacturing devices, unable to form the quality, affecting the stability of the material deposition process, and the dimensional accuracy of the forming materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

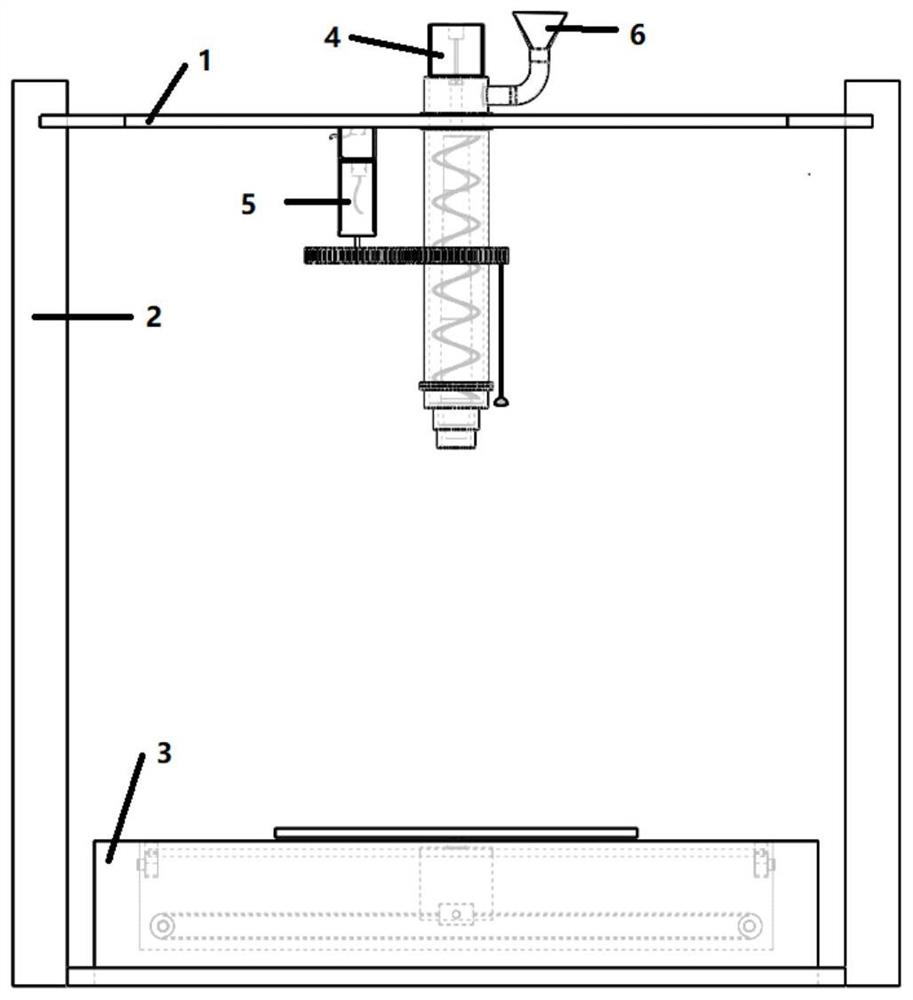

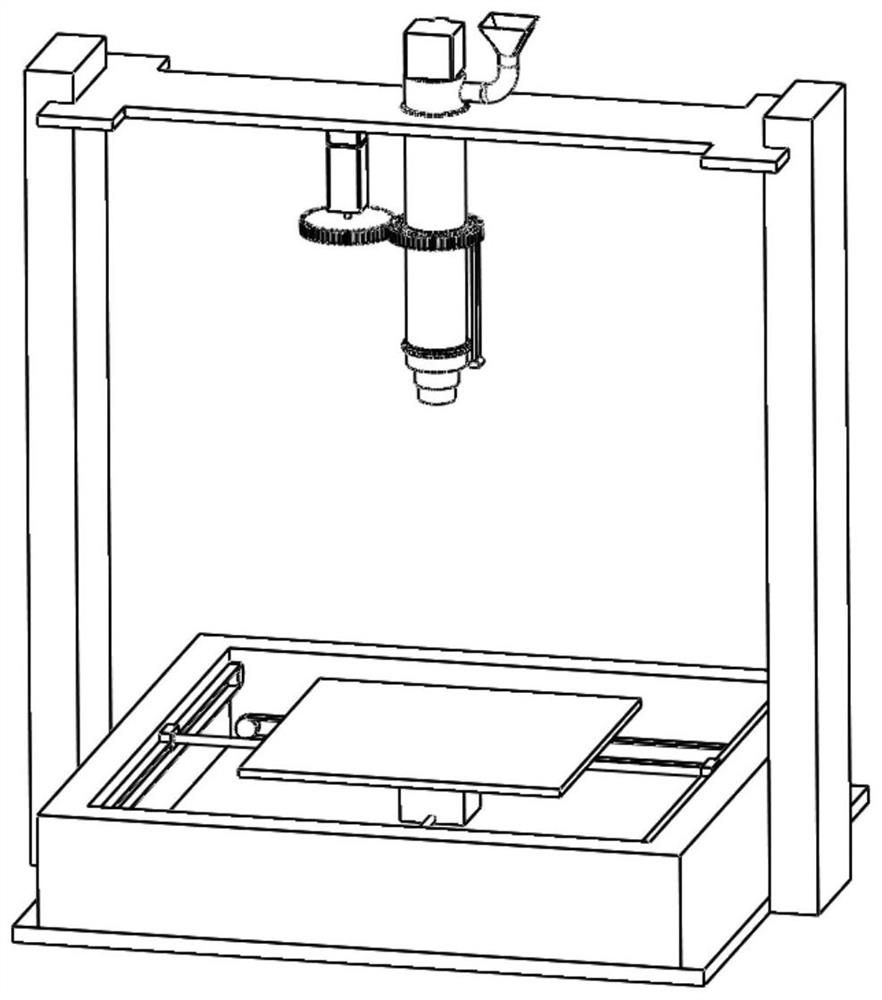

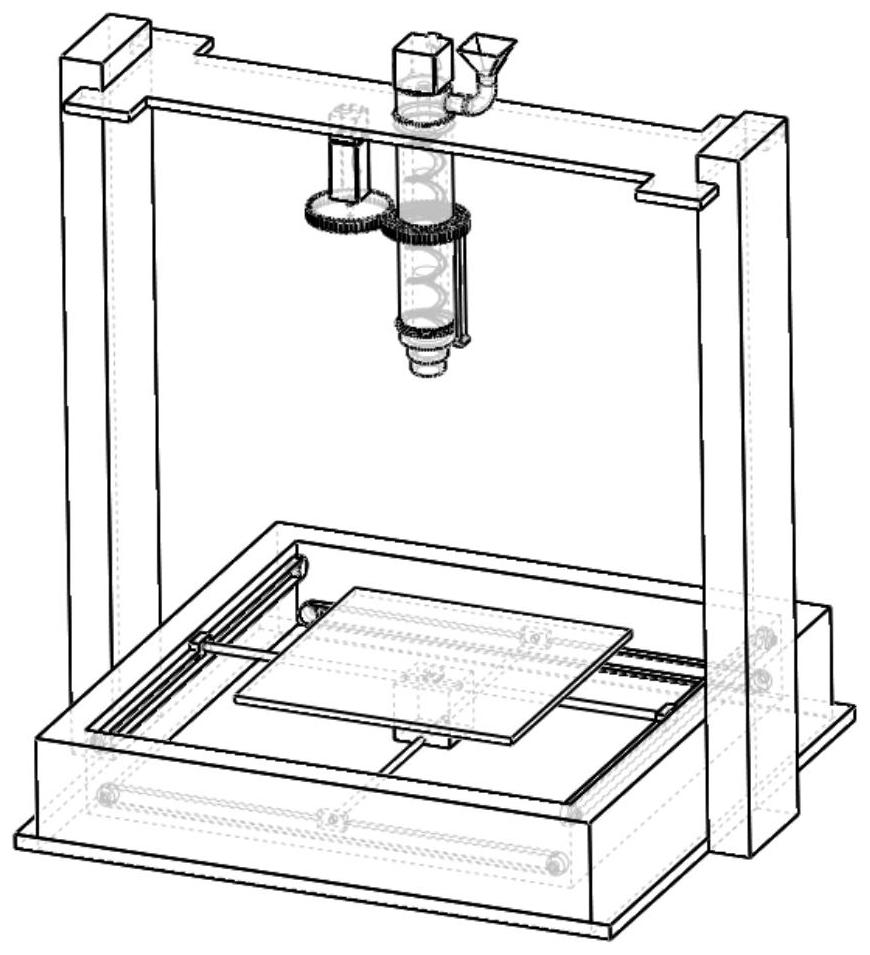

[0051] Such as Figure 1-11 As shown, the present invention provides a large-scale 3D printing device based on a pellet screw extruder, which is applied to the scene of large-format thermoplastic composite material additive manufacturing, and can be customized and small-batch for aerospace, automobile, marine engineering, etc. The rapid prototyping of large-scale parts or equipment provides a reliable means of 3D printing. The invented relative motion design can realize the stable extruding and depositing material of the pellet extruder, and the addition of an infrared heat source can improve the interlayer bonding strength of the deposited material and provide reliable prints.

[0052] A large-scale 3D printing device based on a pellet screw extruder includes: a frame z-axis slide rail 2, a pellet screw extruder, and a printing platform moving device 3 connected to the bottom of the frame z-axis slide rail 2, and the pellet screw extruder The extruder is located above the pr...

Embodiment 2

[0063] On the basis of Embodiment 1, the present invention also provides a working method of a large-scale 3D printing device based on a pellet screw extruder, comprising the following steps:

[0064] Step 1. Use the slicing software supporting the machine to convert the drawing to be printed into a g-code file and import it into the printer;

[0065] Step 2, the computer in the printer reads the code file and controls the screw motor 4 to drive the screw 8 to rotate and heat the screw 8;

[0066]Step 3, the material enters the pellet screw extruder from the conveying device 6, is heated, and is extruded from the nozzle 9 along with the rotation of the screw 8;

[0067] Step 4, the extruded hot-melt material is piled up on the printing platform 15;

[0068] Step 5. The trajectory of the printing platform 15 is controlled by the code, and the printing of each layer is completed through the relative movement of the screw extruder and the printing platform 15;

[0069] Step 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com