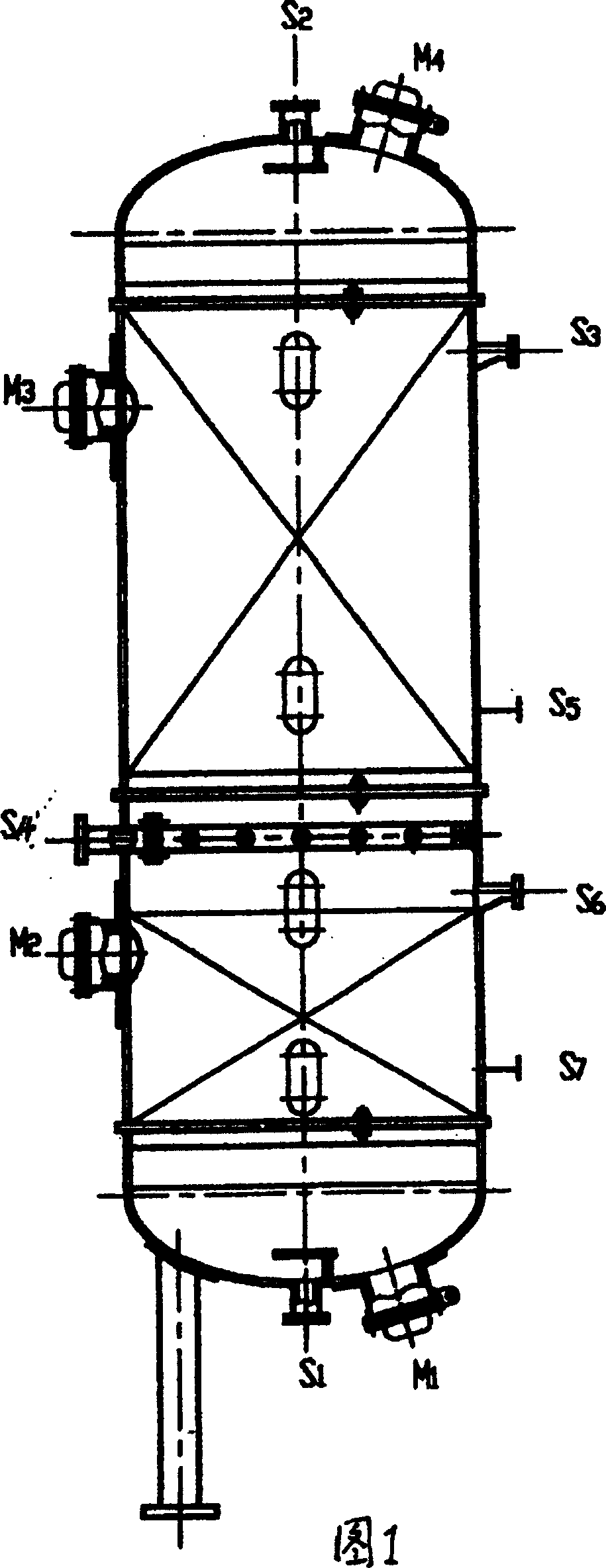

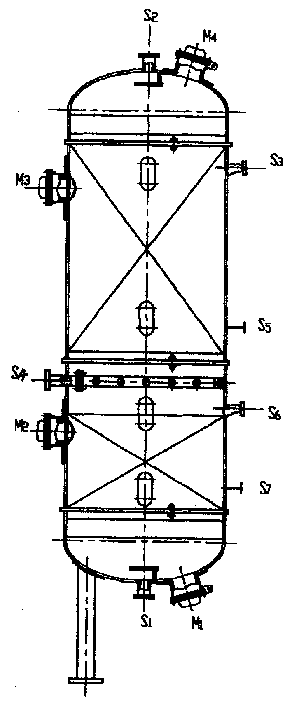

Double chamber bed with floating chamber and full chamber

A full-chamber bed and floating bed technology, applied in ion-exchange water/sewage treatment, etc., can solve the problems of up to 3.0~5.0, the reduction of cycle water production, the decline of resin utilization rate, etc., to achieve high resin utilization rate and cycle water production. The effect of large and small environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The double-chamber floating-full-chamber bed adds a dilution water pipe between the upper chamber and the lower chamber, and the other structures are the same as the double-chamber floating bed. It is designed with sulfuric acid as the regenerating agent on the cation bed, and the sulfuric acid adopts a step-by-step regeneration process. The concentration of sulfuric acid entering the chamber on the positive bed in the first step is 1.5%, the concentration in the second step is 3%, and the concentration of sulfuric acid kept in the lower chamber is 0.7% all the time. To accommodate this step-by-step regeneration process, dilution water is added between the upper and lower chambers. The holes on the dilution water pipe are evenly distributed, and the hole diameter only ensures that the water comes out, and the resin cannot go in. If common hydrochloric acid is used as the regeneration agent, its structure does not need to be changed, that is, it does not need to dilute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com