Method for extracting niobium alloy from niobium-titanium-rich slag and application of solid carbon reducing agent

A technology of reducing agent and solid carbon, applied in the field of extracting niobium alloy, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1

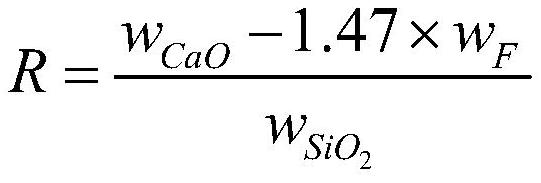

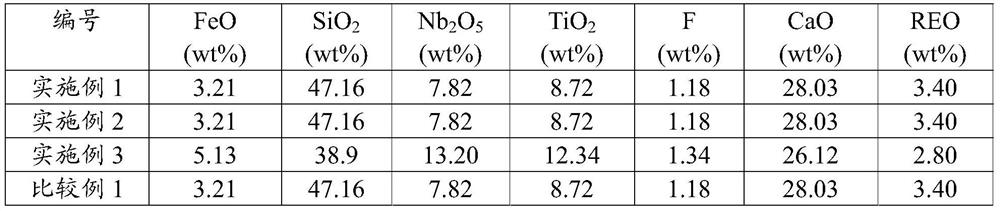

[0067] The main components of niobium-titanium-rich slag raw materials are shown in Table 1. The ash content in the semi-coke is 10.1wt%, the volatile matter content is 13.32wt%, and the fixed carbon content is 76.32wt%. The particle size of semi-coke is recorded as d, 0.1mm≤d≤5mm. The niobium-titanium-rich slag includes niobium-titanium-rich slag raw materials and lime (CaO content 87.32wt%), and its basicity is shown in Table 2.

[0068] Mix niobium-titanium-rich slag, nickel oxide powder and semi-coke evenly, put them into an induction furnace lined with a graphite crucible and heat up to the reaction temperature (T 1 ), and then at the reaction temperature (T 1 ) under reaction t 1 time, niobium-nickel alloy and titanium-containing slag are obtained. The main components of niobium-nickel alloy are shown in Table 3.

[0069] Put niobium-nickel alloy and carbon monoxide at pressure P and temperature T 2 Under the condition of reaction t 2 Time, nickel carbonyl and nio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com