Tough soybean protein-based adhesive, preparation method and application thereof

A technology of soybean protein and soybean protein isolate, which is applied in the field of tough soybean protein-based adhesives and its preparation, can solve the problems of high brittleness, poor water resistance, and low bonding strength, and achieve improved toughness, high bonding strength, and reduced The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of involved glycidylamine comprises the steps:

[0052] (1) Place epichlorohydrin, ammonia water, diethylenetriamine and 1,2,4,5-benzenetetraaldehyde in a molar ratio of 5:1:0.2:0.1 in a three-neck equipped with a condenser and agitator In the flask, stir evenly at 600rpm, add ammonium trifluoride, first react at 23°C for 48h, and then react at 35°C for 3h;

[0053] (2) Vacuum distillation is used to remove epichlorohydrin and ammonium hydroxide in the product after the reaction to obtain a colorless syrup with a branched structure; adding excessive concentration to the colorless syrup is 50% sodium hydroxide The solution was reacted at 20°C for 2 hours. Since the reaction was exothermic, an external ice water cooling circulator was equipped to maintain the temperature; after the reaction was completed, sodium chloride was removed by filtration, and the filtrate was vacuum distilled to obtain glycidylamine.

[0054] The preparation method of invo...

Embodiment 1

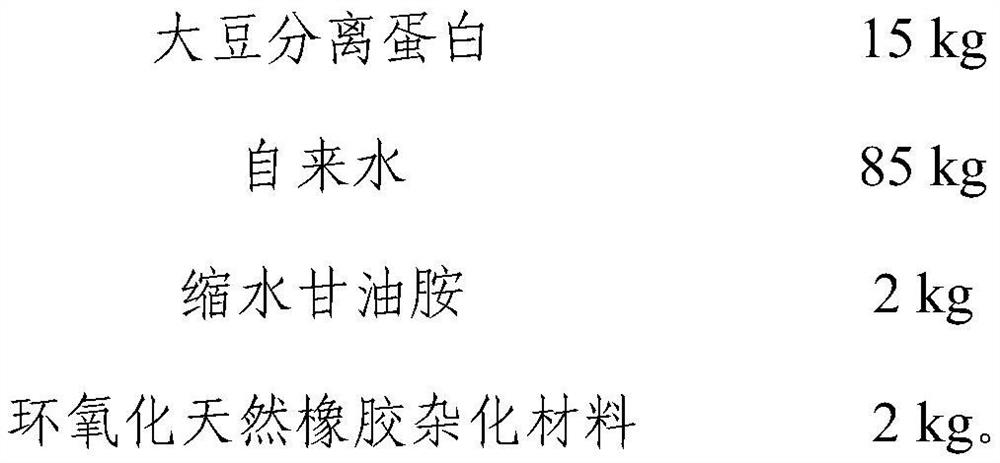

[0059] The present embodiment provides a soybean protein-based adhesive, comprising the following components by weight:

[0060]

[0061] This embodiment also provides the preparation method of the above-mentioned soybean protein-based adhesive, which specifically includes the following steps:

[0062] (1) Add soybean protein isolate to tap water, and stir at room temperature and 800 rpm for 10 minutes to obtain a homogeneous soybean protein adhesive system;

[0063] (2) Add a cross-linking agent to the soybean protein adhesive system, stir at room temperature and 600rpm for 10min (so that the cross-linking agent is uniformly dispersed in the system), add epoxidized natural rubber hybrid material, and Stir at 600rpm for 10min (so that the epoxidized natural rubber hybrid material is uniformly dispersed in the system), and it is ready.

Embodiment 2

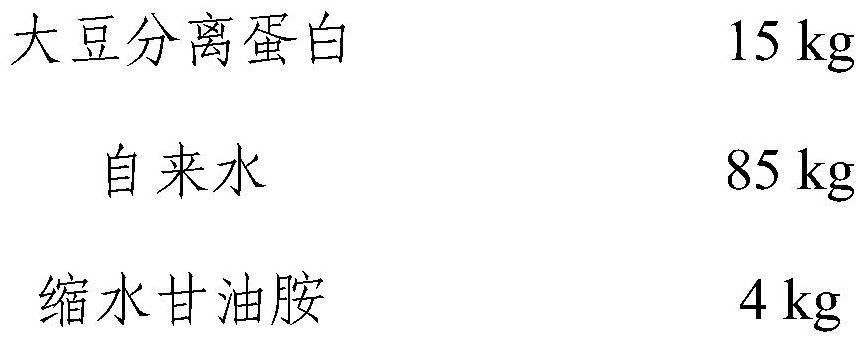

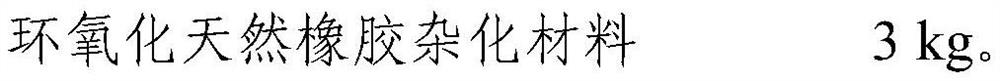

[0065] The present embodiment provides a soybean protein-based adhesive, comprising the following components by weight:

[0066]

[0067]

[0068] The preparation method of the soybean protein-based adhesive provided in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com