High-strength steel medium-thickness plate stamping part capable of preventing edge cracking, manufacturing method and application

A production method and technology of high-strength steel, applied in vehicle parts, transportation and packaging, etc., can solve problems such as poor mechanical properties of plates, low material elongation, and large differences in effects, and achieve the elimination of flanging cracks, simple repair methods, and consumption. The effect of less resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

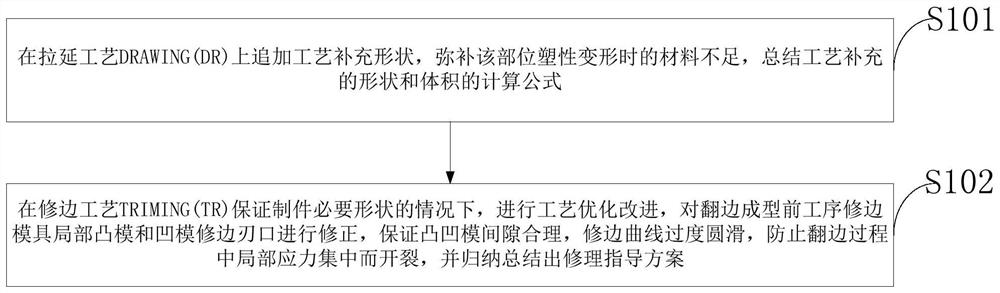

[0058] The manufacturing method of the high-strength steel medium-thick plate stamping parts for preventing edge cracking provided by the embodiments of the present invention includes drawing process DRAWING (DR), trimming process TRIMING (TR), and flanging process FLANG (FL).

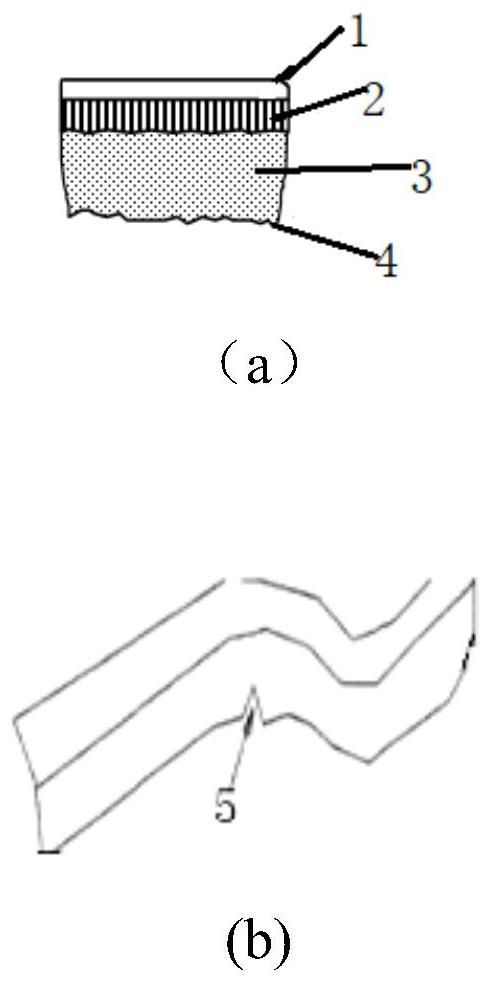

[0059] In the trimming process (TR), when the sheet is punched and separated along a certain contour shape, it is easy to produce defects such as work hardening bands, burrs and microcracks in the thickness direction, including the following four areas (sag band 1 , bright zone 2, fracture zone 3, and burr zone 4 are shown in the figure, such as 2 (a) The defects produced on the section after blanking of the sheet material reduce the toughness and plasticity of the sheet material, and the deformation ability decreases. These defects will be in the subsequent flanging In the process, it becomes the fracture source of edge fracture, that is, the inner curved flanging cracking zone 5. See figure 2 (b). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com