A kind of control system of numerical control non-falling wheel lathe and its application method

A technology of numerical control system and control system, applied in the direction of digital control, electrical program control, etc., can solve the problems of shortened detection cycle, difficult equipment diagnosis and maintenance, and high technical requirements, and achieves convenient operation, strong practicability, and repair method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

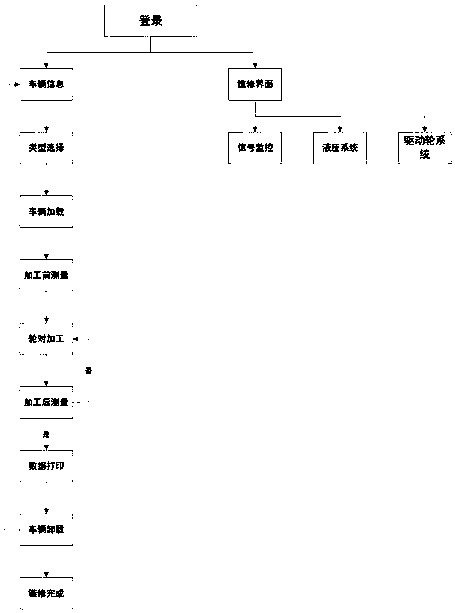

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0024] Such as figure 1 Shown, a kind of numerical control does not drop wheel lathe control system, comprises Siemens 840dsl numerical control system PLC, NCU unit and man-machine interface HMI, it is characterized in that: described NCU unit is the central control unit of Siemens 840dsl numerical control system PLC, NCU unit Connect with Siemens 840dsl numerical control system PLC through Ethernet, the human-machine interface HMI is the login interface and realize the information loading and unloading function through data communication with NCU unit, communicate with Siemens 840dsl numerical control system PLC through NCU unit and control the lathe For the processing of locomotive wheel sets and the equipment diagnosis of turning lathe, the Siemens 840dsl numerical control system PLC includes a wheel set measurement module, a tool compensation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com