Preparation method of MIL-101 (Cr)-coated AC composite material and application thereof

A technology of composite materials and activated carbon, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of weak interaction, etc., and achieve the effect of increasing micropore volume, reducing pore diameter and pore volume, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

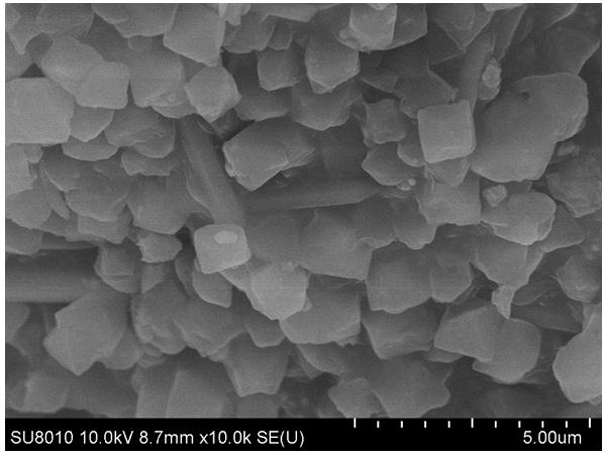

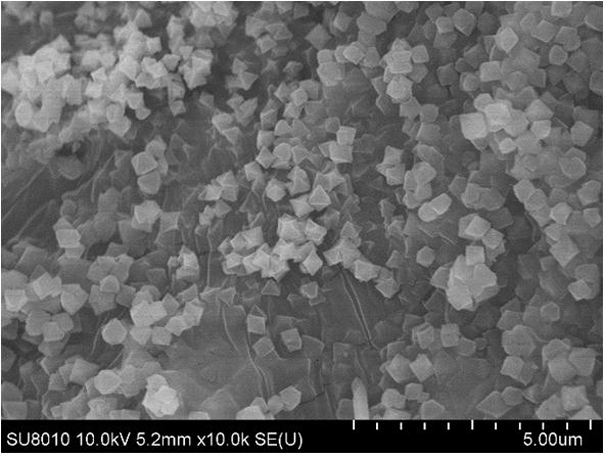

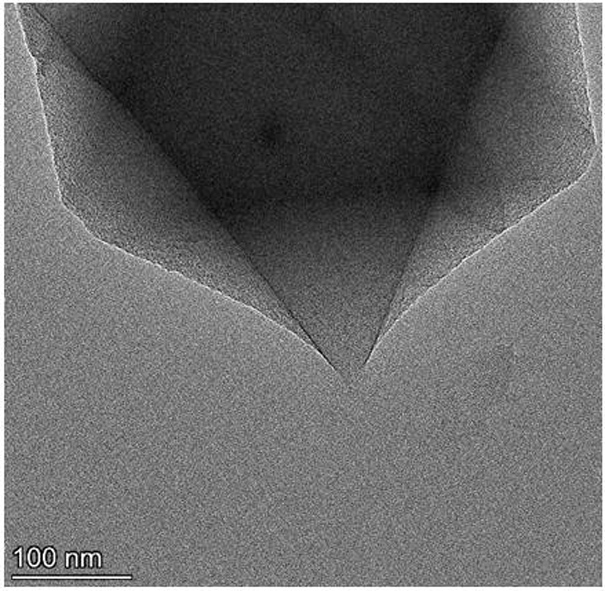

[0035] 4.034g Cr(NO 3 ) 3 9H 2 O. Add 1.67g of terephthalic acid and 50mg of ball-milled AC to 50ml of deionized water, mix well, then add 1mL of hydrochloric acid (36wt%), stir for 1h, ultrasonic for 40min, pour it into a hydrothermal reaction kettle, and heat it at a temperature of 190 Under the condition of ℃, hydrothermal for 12h, after the reaction was completed, cooled to room temperature, and the green precipitate was obtained by centrifugation. Disperse the precipitate in 50mL N,N-dimethylformamide (DMF) solution and wash 3 times, disperse the washed precipitate in 50ml absolute ethanol (ETOH), and conduct hydrothermal reaction at a temperature of 80°C After 12 hours, after cooling, the product was collected by centrifugation. The resulting product was washed three times with absolute ethanol to completely remove the solvent DMF, and then centrifuged to obtain a solid. The solid was dried in a vacuum oven at 80°C for 12 hours to obtain MIL-101(Cr)@AC powder.

[0036...

Embodiment 2

[0040] 4.035g Cr(NO 3 ) 3 9H 2 O, 1.67g of terephthalic acid and 80mg of ball-milled AC were added to 50ml of deionized water, mixed evenly, then 1mL of hydrochloric acid (36wt%) was added, stirred for 2h, ultrasonicated for 40min, poured into a hydrothermal reaction kettle, and heated at a temperature of 200 Under the condition of ℃, hydrothermal for 12h, after the reaction was completed, cooled to room temperature, and the green precipitate was obtained by centrifugation. Disperse the precipitate in 50mL N,N-dimethylformamide (DMF) solution and wash 3 times, disperse the washed precipitate in 50ml absolute ethanol (ETOH), and conduct hydrothermal reaction at a temperature of 80°C After 12 hours, after cooling, the product was collected by centrifugation. The resulting product was washed three times with absolute ethanol to completely remove the solvent DMF, and then centrifuged to obtain a solid. The solid was dried in a vacuum oven at 85°C for 12 hours to obtain MIL-101...

Embodiment 3

[0043] 4.035g Cr(NO 3 ) 3 9H 2 O, 1.67g of terephthalic acid and 100mg of ball-milled AC were added to 50ml of deionized water, mixed evenly, then 1mL of hydrochloric acid (36wt'%) was added, stirred for 2h, ultrasonicated for 40min, poured into a hydrothermal reaction kettle, at temperature Under the condition of 200 ℃, hydrothermal for 12h, after the reaction was completed, cooled to room temperature, and the green precipitate was obtained by centrifugation. Disperse the precipitate in 50mL N,N-dimethylformamide (DMF) solution and wash 3 times, disperse the washed precipitate in 50ml absolute ethanol (ETOH), and conduct hydrothermal reaction at a temperature of 80°C After 12 hours, after cooling, the product was collected by centrifugation. The resulting product was washed three times with absolute ethanol to completely remove the solvent DMF, and then centrifuged to obtain a solid. The solid was dried in a vacuum oven at 85°C for 12 hours to obtain MIL-101(Cr)@AC powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com