Pressure vessel external cooling system for floating nuclear power station

A pressure vessel and external cooling technology, applied in nuclear power generation, cooling devices, nuclear engineering, etc., can solve the problems of threatening the integrity of the containment, loss of cooling capacity, and inability to operate for a long time, so as to avoid heat transfer deterioration and reduce melt-through risk, swift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

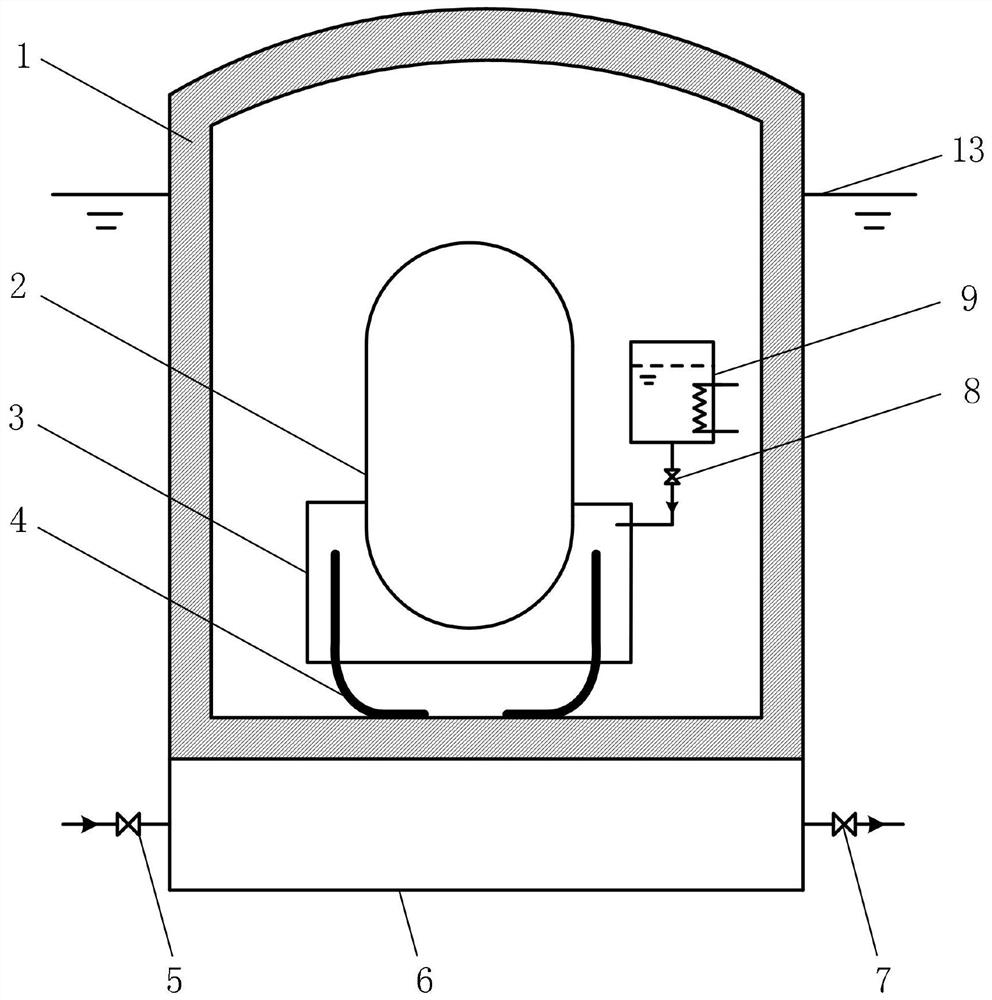

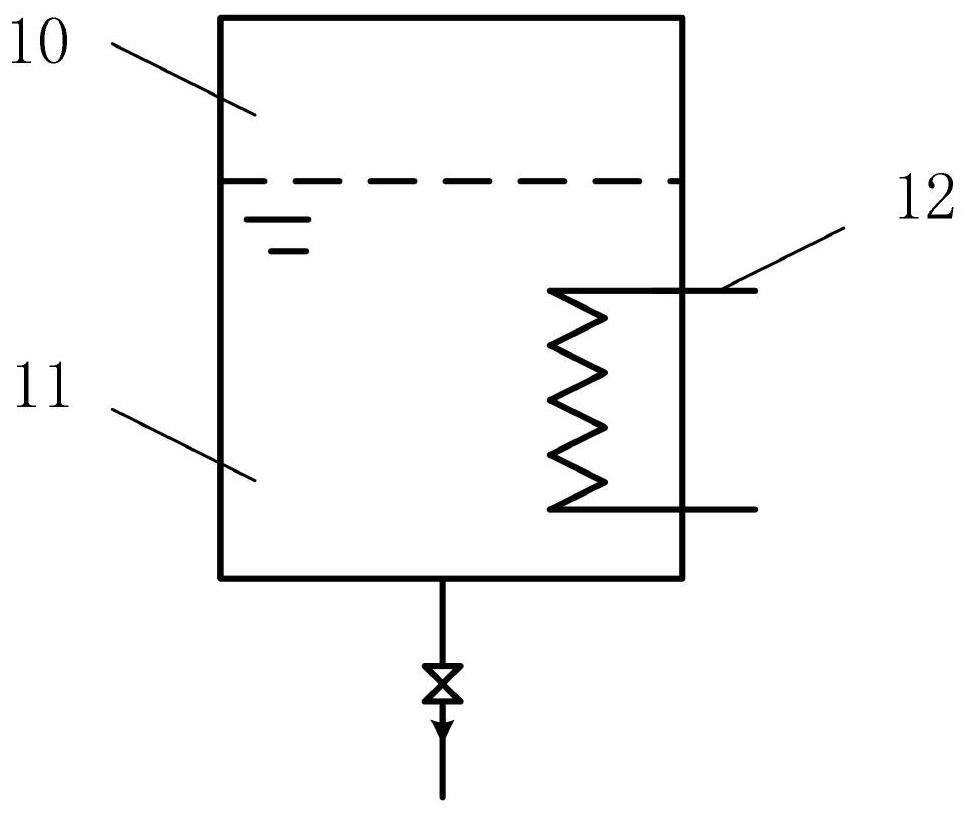

[0030] An external cooling system for a pressure vessel for a floating nuclear power plant includes a containment vessel 1 , a pressure vessel 2 , a liquid gallium collection tank 3 , a heat pipe 4 , a cooling chamber 6 and a gallium storage tank 9 .

[0031] The containment vessel 1 is arranged in the sea environment 13, and the containment vessel 1 has an accommodating cavity.

[0032] The pressure vessel 2 and the liquid gallium collection box 3 are arranged up and down, and are located in the accommodating cavity of the containment vessel 1 ; the lower head of the pressure vessel 2 is arranged in the liquid gallium collection box 3 .

[0033] One end of the heat pipe 4 is inserted into the liquid gallium collection box 3 and is set as the evaporation section; the other end of the heat pipe 4 is arranged on the side of the liquid gallium collection box 3 away from the pressure vessel 2 and is fixed with the inner wall of the bottom of the containment vessel 1 connection, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com