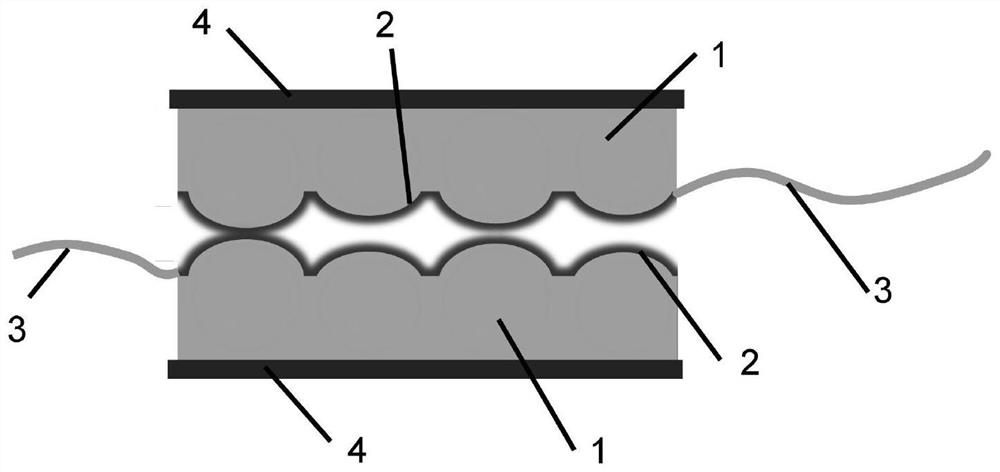

Flexible mechanical sensor of bionic microstructure and preparation method thereof

A flexible mechanics and sensor technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve the problems of complex preparation process, difficulty in mass production, high cost, etc., and achieve improved sensitivity and measurement range, excellent reversible deformation characteristics and stability The effect of improved performance, sensitivity and measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In this embodiment, the flexible mechanical sensor disclosed herein is prepared by using the following steps.

[0059] Step 1, 30 g of thermal expansion microspheres were added to 70 g of platinum catalyzed silicone rubber EcoFlex (A component + B component) high molecular elastomeric solution, which was mixed with a planet mixer (AR-100, Thinky, Japan), removing bubbles, The thermal expanded microsphere / silicone rubber elastomer mixture is obtained;

[0060] Step 2, the thickness is controlled by the thickness, the thermal expansion microsphere / silicone rubber elastomer is poured onto the PET substrate, and the scraper height is adjusted to obtain a film embryo body having a thickness of 500 μm;

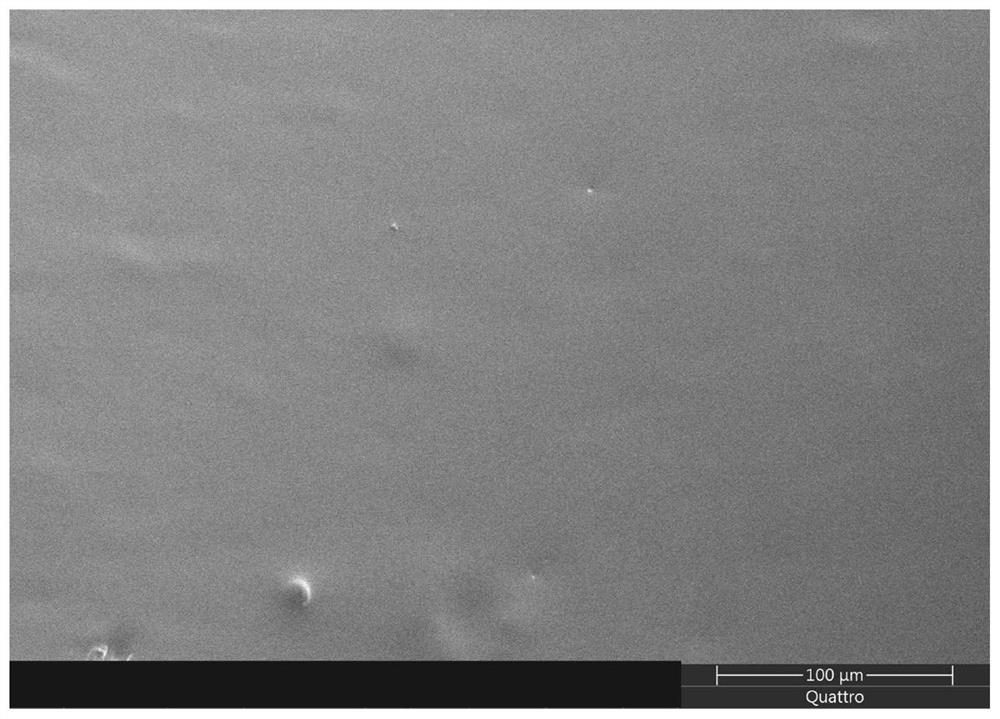

[0061] Step three, the obtained thin film embryo body is placed in a vacuum drying tank, set the temperature of 40 ° C, solidified to obtain thermal expansion microspheres / silicone rubber film material, surface scanning electron microscope figure 2 As shown, the surface is ...

Embodiment 2

[0067] Step 1, 35 g of thermal expansion microspheres were added to 65 g of polydimethyl silicone rubber PDMS (from 10: 1: 1: 1) solution, and mixed with high-speed planet mixers (AR-100, Thinky, Japan). Bubbles to obtain thermal expansion microspheres / PDMS mixture;

[0068] Step 2, pour the thermal expansion microspheres / PDMS mixed liquid onto the PET substrate, adjusting the scraper height of 100 μm, and prepared a thin film embryo body having a thickness of about 1 mm;

[0069] Step three, the resulting film embryo body is placed in a vacuum drying tank, and the temperature is 50 ° C, solidified formation to obtain thermal expansion microspheres / PDMS composite film material;

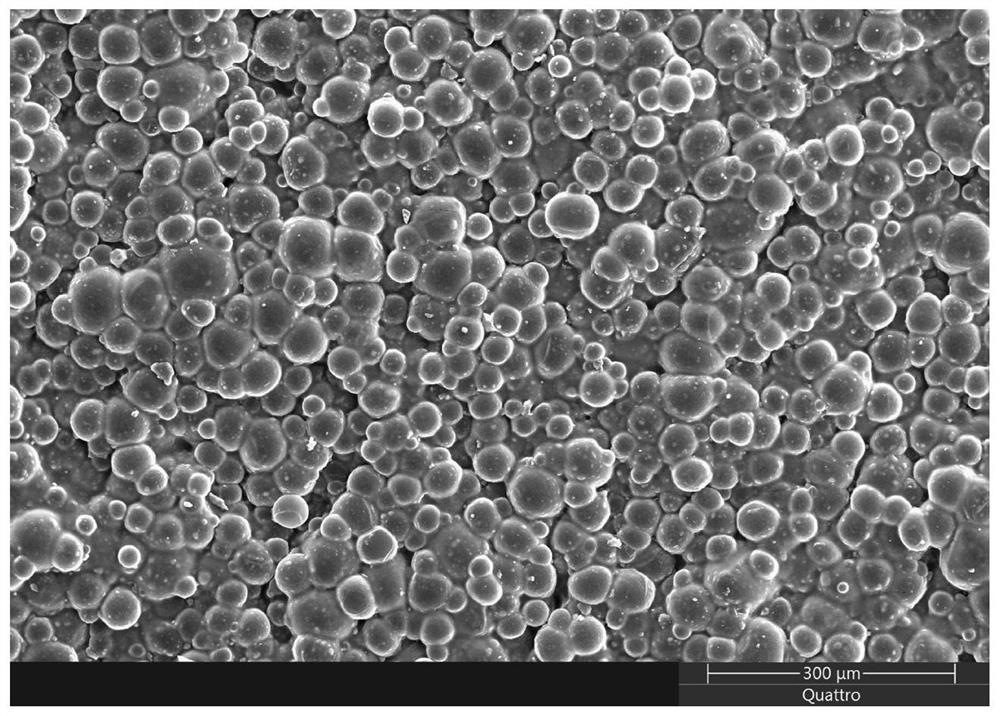

[0070] Step 4, the obtained film material is again placed in a vacuum drying tank at a high temperature of 110 ° C for 2 min, so that the internal microspheres are expanded from the surface of the substrate to protrude, thereby obtaining surface projection microstructure film materials, such as Imag...

Embodiment 3

[0075] Step 1, 40 g of thermal expansion microspheres are added to 60 g of silicone rubber EcoFlex (A component + B component) solution, which is uniform with high-speed planetary mixer (AR-100, Thinky, Japan), remove bubbles to obtain thermal expansion microspheres / silicon Rubber mixture;

[0076] Step 2, pour the thermal expansion microsphere / silicone rubber mixed liquid onto the PET substrate, adjusting the height of the doctor blade to 1 mm, and prepared a thin film embryo body having a thickness of about 1 mm;

[0077] Step three, the resulting film is placed in a vacuum drying tank, and the temperature is 50 ° C, cured molding to obtain a thermal expansion microsphere / silicone rubber film material;

[0078] Step 4, the obtained film material is again placed in a vacuum drying tank at a high temperature of 130 ° C for 5 min, so that the internal microspheres are expanded from the surface of the substrate to protrude, thereby obtaining a surface-projected bionic microstr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com