Oxygen-doped toughened aluminum-based amorphous composite material and preparation method thereof

An amorphous composite material and oxygen doping technology, applied in the field of amorphous alloys, can solve the problems of lack of simple process and complex process of aluminum-based amorphous composite materials, avoid adverse effects, achieve mechanical properties, and improve plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

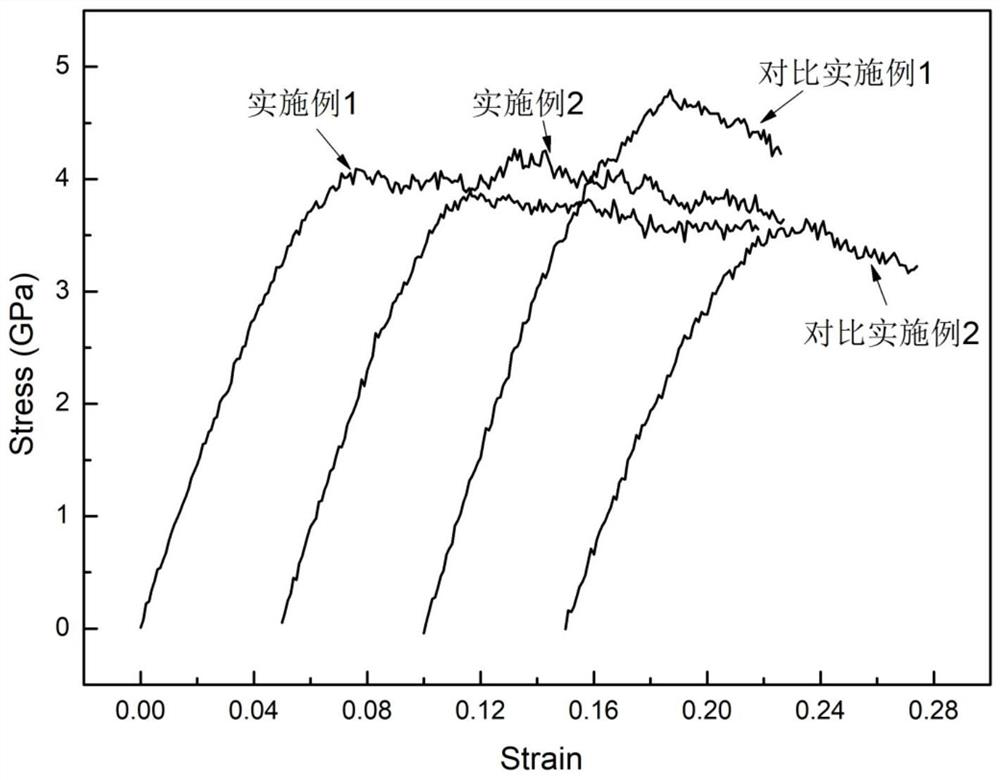

Embodiment 1

[0028] Prepare Al-Ni-Y amorphous composite material, the preparation process includes the following steps:

[0029] (1) Weigh 30g of Al, Ni, and Y pure metal raw materials with a purity greater than 99.99% according to the ratio of atomic ratio Al:Ni:Y of 80.0%:15.0%:5.0%, mix them, and heat and melt them in a melting furnace ;

[0030] (2) Continue heating and control the temperature in the furnace to a constant temperature of 1050°C, blow oxygen into the alloy melt, use a temperature measuring oxygen meter to measure the dissolved oxygen content in real time, and stop heating when the atomic percentage of oxygen reaches 0.7%.

[0031] (3) Rapidly transfer the alloy melt into a copper mold and water-cool to prepare a rod-shaped material with a diameter of 1 mm.

Embodiment 2

[0033] Prepare Al-Ni-Y amorphous composite material, the preparation process includes the following steps:

[0034] (1) Weigh 30g of Al, Ni, and Y pure metal raw materials with a purity greater than 99.99% according to the ratio of atomic ratio Al:Ni:Y of 80.0%:15.0%:5.0%, mix them, and heat and melt them in a melting furnace ;

[0035] (2) Continue heating and control the temperature in the furnace to a constant temperature of 1050°C, blow oxygen into the alloy melt, measure the dissolved oxygen content in real time with a temperature measuring oxygen meter, and stop heating when the atomic percentage of oxygen reaches 0.4%.

[0036] (3) Rapidly transfer the alloy melt into a copper mold and water-cool to prepare a rod-shaped material with a diameter of 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com