On-line plugging method for debenzolization tower

A method of plugging leaks and a technology for removing benzene towers, which can be applied in the directions of products, climate sustainability, reagents, etc., and can solve the problems of shutdown of crude benzene units, low tensile strength, plasticity, toughness and elastic modulus, and poor welding performance. , to meet the requirements of temperature and pressure, to ensure long-term safe use, high strength and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

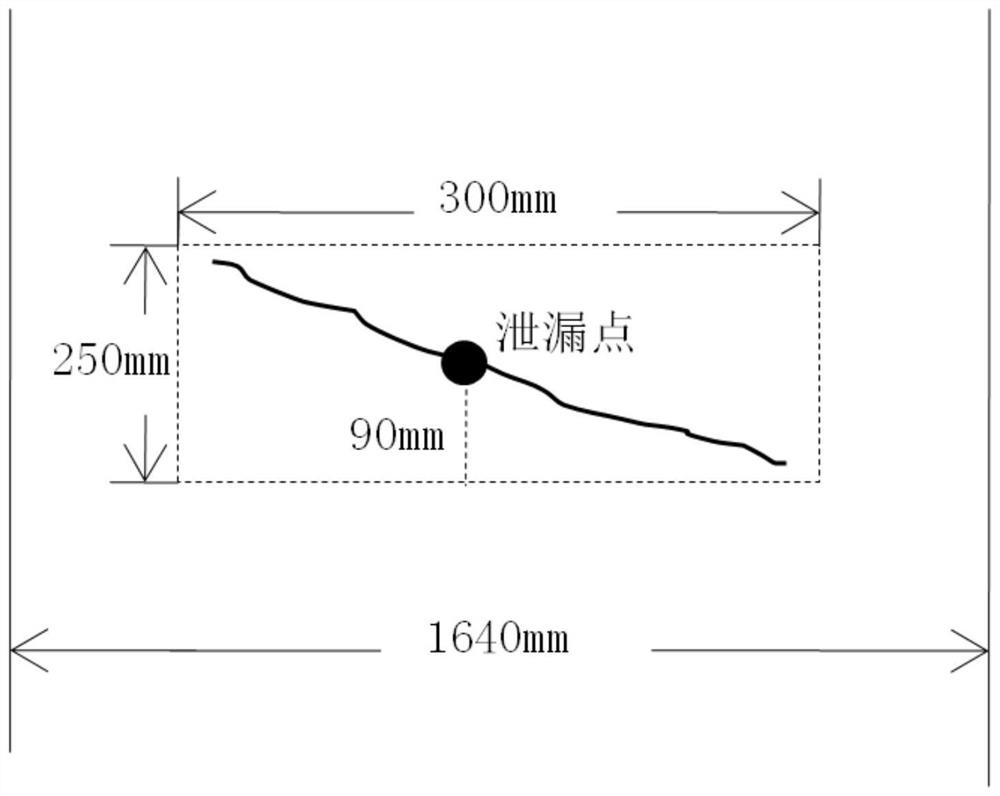

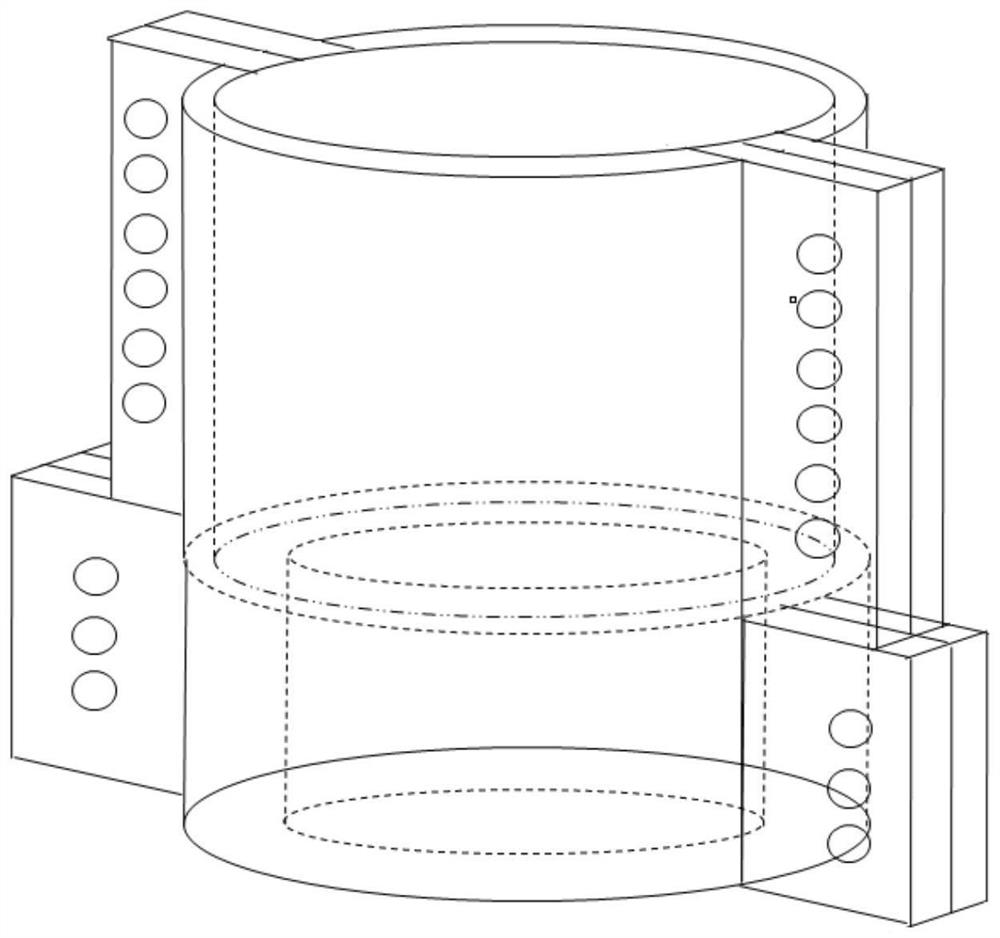

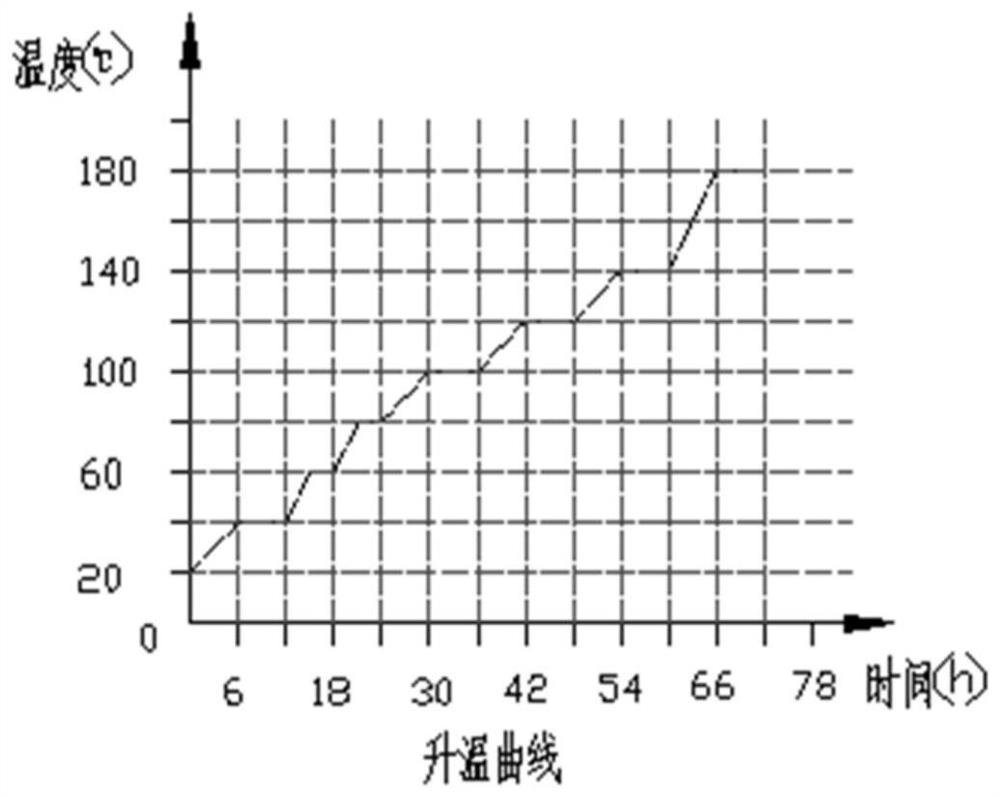

[0062] This example is for figure 1 The shown one has a total of 28 rings, a diameter of 1640mm, a total height of 33883mm, and the tower ring is made of HT200 to plug the cracks in the leaking part of the debenzene tower. Cracks appeared at the flange neck of the seventh section of the tower body (down from the tower cover) of the debenzene tower. The crack length reached 340 mm, and the crack was inclined at 30 degrees. The leak point was located in the middle of the crack, and a large amount of benzene vapor came from the crack When spraying out, the pressure inside the tower at this part is about 40KPa, and the temperature is about 180°C. The online plugging method of debenzene tower used in this implementation is as follows:

[0063] Step 1: Observe the leakage area and leak point, use a rectangular frame with a length of 300mm and a width of 250mm to circle the leakage crack on the surface of the tower ring at the flange neck of the tower ring in Section 7, and place th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com