Method for promoting vertical shaft shale gas exploitation through horizontal multilateral well burning explosion fracturing

A technology for horizontal branch wells and shale gas exploitation, which is applied in the fields of exploitation fluids, wellbore/well components, earth-moving drilling, etc. It can solve the problems of single fracture expansion, increase economic cost, long hydraulic fracturing time, etc., and achieve economical savings. Water resources, ensure the effect of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

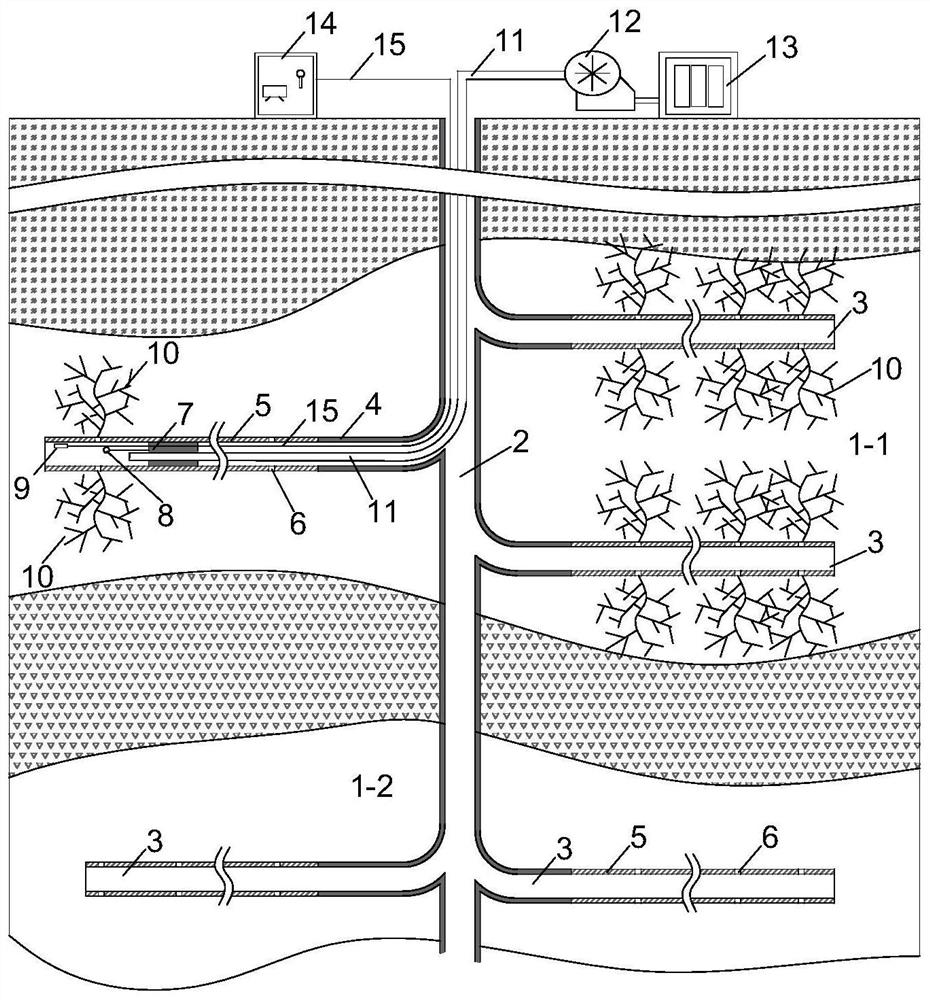

[0019] Example 1: Two shale reservoirs in the formation of a certain region found through geological exploration, respectively, the first page of the rock reservoir 1-1 and the second rock reservoir 1-2, first page The rock reservoir 1-1 is above the second page of the rock reservoir 1-2, such as figure 1 As shown, shale gas mining is performed using the method of the present invention, and the specific steps are:

[0020] A. Take a shaft 2 from the ground to the first page of the rock reservoir 1-1 until the shaft 2 is stopped at the deepest place of the shaft reservoir, and the sleeve 4 is mounted to the shaft 2 in the process of shaft 2. , Complete the setting of the shaft 2;

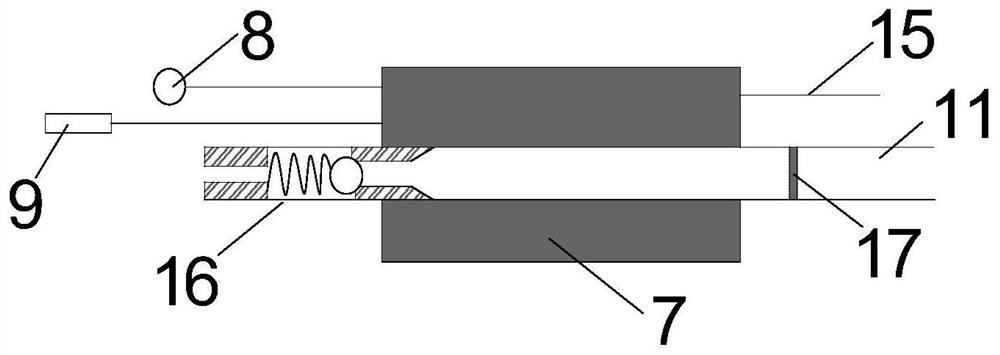

[0021] B. Use the directional drill to extend into the shaft 2 and reach the first page of the rock storage layer 1-1, from the shaft 2 to the first page of the rock reservoir 1-1, multiple horizontal bonding wells 3, and in each The horizontal branch well 3 is supported in combination with the sleeve 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com