Mucor circinelloides CAULIU-FUNGUS-1 and application thereof

A technology of Mucor circinigii, cgmccno.21479, which is applied in the field of composition, bacterial agent, water-phase product of hydrothermal conversion, and Mucor circinifolia, which can solve the problems of restricting the green development of hydrothermal conversion technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Example 1 Isolation, purification and preservation of Mucor circinosa CAULIU-FUNGUS-1

[0082] 1. Preparation of culture medium:

[0083] PDA medium: Wash and peel the potatoes first, then weigh 200g of potatoes and cut them into small pieces, boil them in water, and filter them with gauze. Heat, add 15-20g of agar according to the actual experiment needs, continue to heat and mix well, after the agar is dissolved, add 20g of glucose, stir evenly, after cooling slightly, make up water to 1000ml, and sterilize at 115°C for 20 minutes.

[0084] PDB medium: Wash and peel the potatoes first, then weigh 200g of potatoes and cut them into small pieces, add water to boil, filter with gauze, add 20g of glucose, stir evenly, after cooling down slightly, add water to 1000ml, and sterilize at 115°C 20 minutes.

[0085] 2. Screening, isolation, purification and preservation of strains

[0086] Sample Collection

[0087] Mucor volvulus CAULIU-FUNGUS-1 was obtained by screening, ...

Embodiment 2

[0093] Example 2 Degradation of microalgae by using Mucor circinatus CAULIU-FUNGUS-1 for hydrothermal transformation of water phase

[0094] Taking the water phase product of microalgae hydrothermal conversion as the processing object, the property parameters of the water phase product of microalgae hydrothermal conversion are as follows: pH8.8, chemical oxygen demand (COD) is 101.1g / L, total nitrogen (TN) content is 22.3 mg / L.

[0095] The method for degrading microalgae hydrothermal conversion water phase by using Mucor circinatus CAULIU-FUNGUS-1 comprises the following steps:

[0096] (1) Inoculate Mucor circiniferatum into PDA medium, culture at 28°C for 48 hours, and prepare fungus cake with a 6mm hole punch.

[0097] (2) Inoculate 5 fungus cakes from step (1) into 50 ml of PDB medium containing 20% hydrothermal conversion water phase product, and shake culture at 28°C.

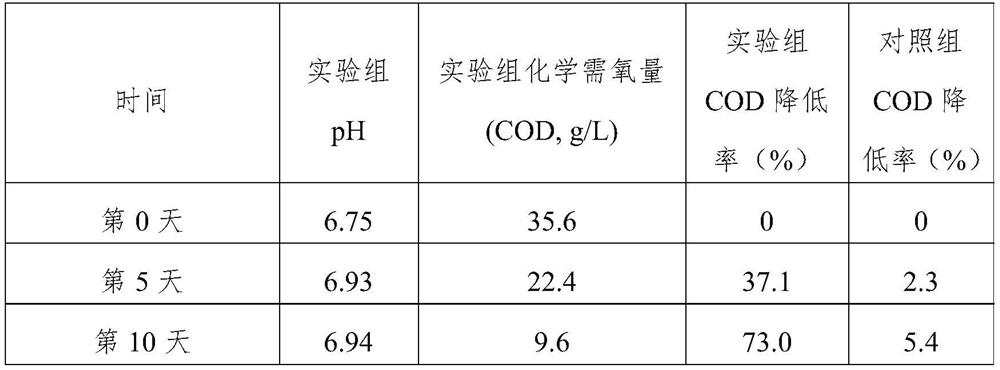

[0098] (3) On the 0th day, the 5th day, and the 10th day, respectively, take 2ml of the culture a...

Embodiment 3

[0111] Example 3 Degradation of straw by using Mucor circinosa CAULIU-FUNGUS-1 for hydrothermal conversion of water phase

[0112] Taking the water phase product of straw hydrothermal conversion as the processing object, the property parameters of the water phase product of straw hydrothermal conversion are as follows: pH3.8, chemical oxygen demand (COD) is 81.1g / L.

[0113] The method for degrading straw by using Mucor circinatus CAULIU-FUNGUS-1 for hydrothermal transformation of water phase comprises the following steps:

[0114] (1) Inoculate Mucor circiniferatum into PDA medium, culture at 28°C for 48 hours, and prepare fungus cake with a 6mm hole punch.

[0115] (2) Inoculate 5 fungus cakes from step (1) into 50 ml of PDB medium containing 20% hydrothermal conversion water phase product, and shake culture at 28°C.

[0116] (3) On the 0th day, the 5th day, and the 10th day, respectively, take 2ml of the culture and centrifuge at 12000rpm for 10min, measure the COD of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com