High-strength photoreversible adhesive, and preparation method and application thereof

A high-intensity light, adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the adverse effects of polymer segment freezing, inability to react, and light-induced reversible adhesive bond strength And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0131] Adhesive structural formula:

[0132]

[0133] 0

[0134] A is

[0135]

[0136] B is:

[0137]

[0138] a=19

[0139] D is:

[0140]

[0141] b=4

[0142] R is

[0143]

[0144] Preparation methods include:

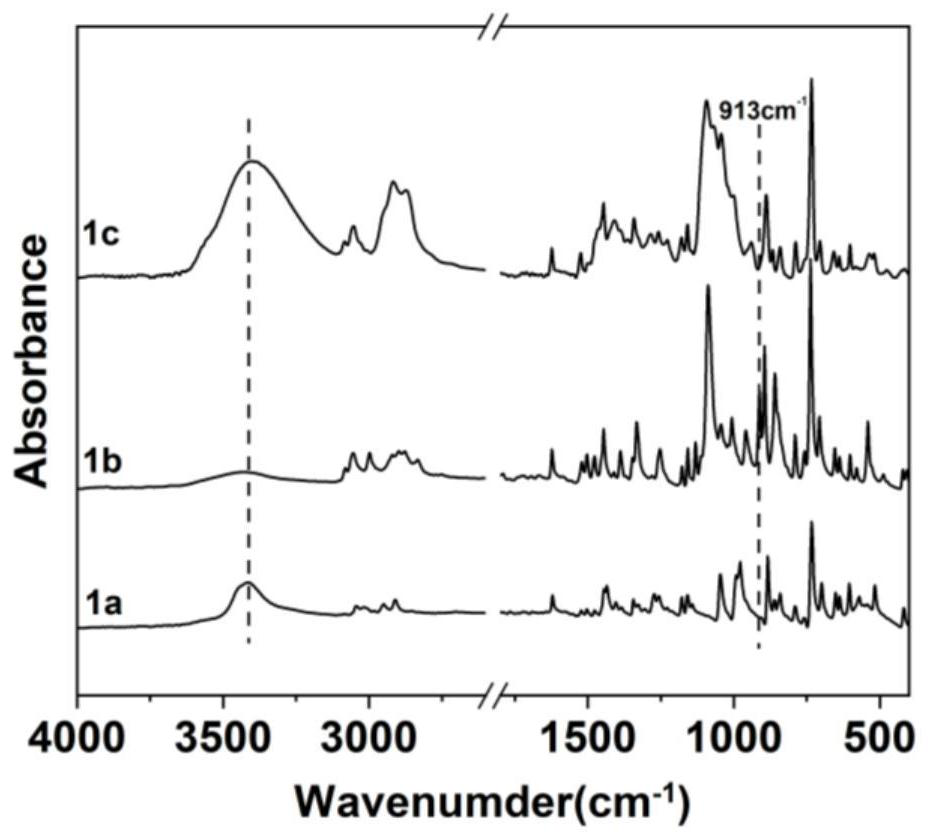

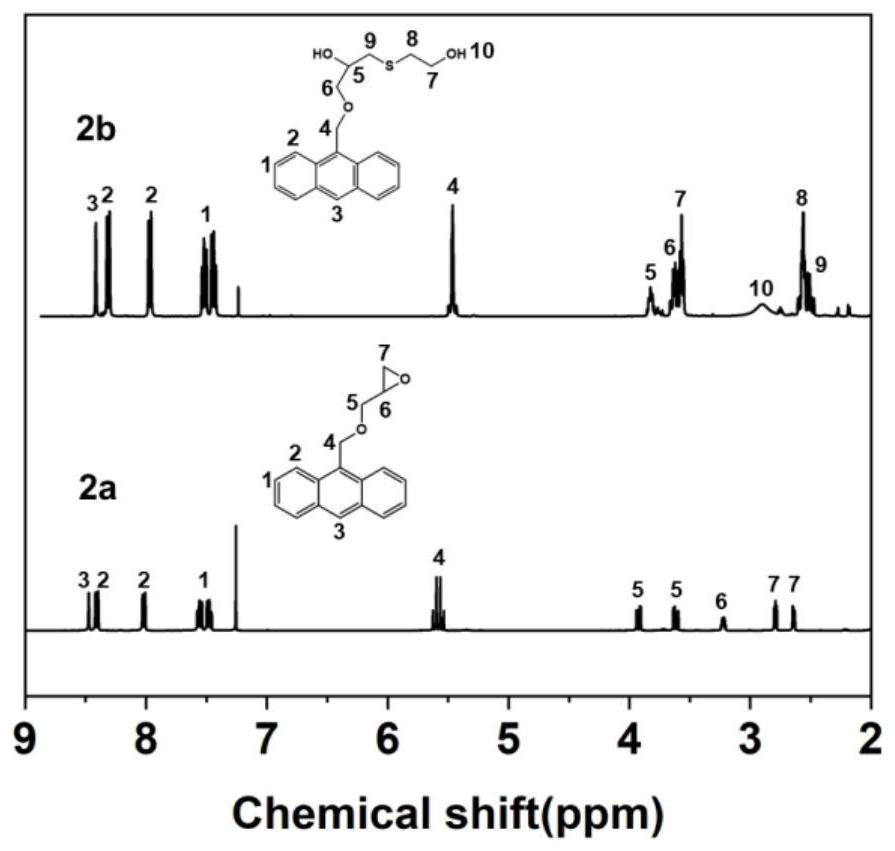

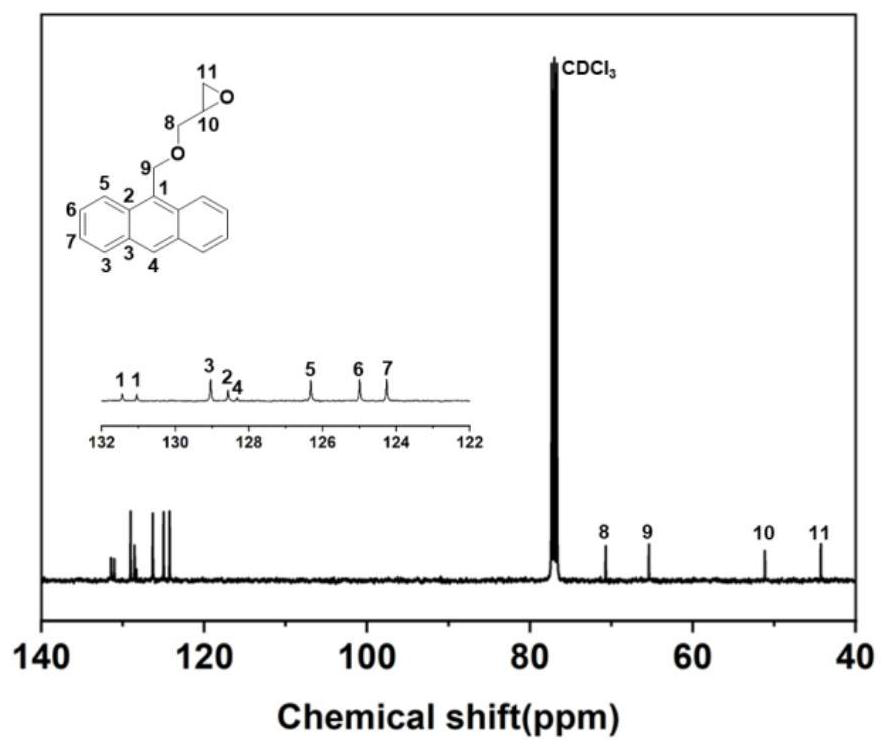

[0145] 1) Preparation of anthracene-containing epoxidation products: Dissolve 1 mol of 9-anthracene methanol (AM) raw material in 25 mol of non-polar solvent toluene, then add 8 mol of epichlorohydrin, keep the temperature in a water bath at 65°C, and then add 3 mol of of sodium hydroxide and 0.02 mol of tetramethylammonium bromide (TMAB). Insulated and stirred for 4 hours, centrifuged, toluene extracted, rotary evaporated and vacuum dried to obtain an epoxidized product containing anthracenyl groups——9-anthracenemethanol epoxide (AER);

[0146] 2) Preparation of double-terminal hydroxyl compounds containing anthracenyl side chains: Step 1) Mix 0.5 mol of 9-anthracene methano...

Embodiment 2

[0175] The structural formula of adhesive is the same as embodiment 1.

[0176] Preparation methods include:

[0177] 1) Preparation of anthracene-containing epoxidation products: Dissolve 1 mol of 9-anthracene methanol (AM) raw material in 20 mol of non-polar solvent toluene, then add 5 mol of epichlorohydrin, keep the temperature in a water bath at 60°C, and then add 2 mol of Sodium hydroxide and 0.01 mol of tetramethylammonium bromide (TMAB). Insulated and stirred for 6 hours, centrifuged, toluene extracted, rotary evaporated and vacuum dried to obtain an epoxidized product containing anthracenyl groups—9-anthracenemethanol epoxide (AER);

[0178] 2) Preparation of double-terminal hydroxyl compounds containing anthracenyl side chains: Step 1) Mix 0.5 mol of 9-anthracene methanol epoxide with 0.5 mol mercaptoethanol, dissolve in 10 mol toluene, and add DMP in 0.5% of the mass fraction -30 promoter, after stirring evenly, react at room temperature (20°C) for 3h, and obtain ...

Embodiment 3

[0206] Adhesive structural formula is the same as embodiment 1.

[0207] Preparation methods include:

[0208] 1) Preparation of anthracene-containing epoxidation products: Dissolve 1 mol of 9-anthracene methanol (AM) raw material in 30 mol of non-polar solvent toluene, then add 10 mol of epichlorohydrin, keep the temperature in a water bath at 70°C, and then add 4 mol of of sodium hydroxide and 0.03 mol of tetramethylammonium bromide (TMAB). Insulated and stirred for 6 hours, centrifuged, toluene extracted, rotary evaporated and vacuum dried to obtain an epoxidized product containing anthracenyl groups - 9-anthracenemethanol epoxide (AER);

[0209] 2) Preparation of double-terminal hydroxyl compounds containing anthracenyl side chains: Step 1) Mix 0.5mol of 9-anthracene methanol epoxide with 0.55mol mercaptoethanol, dissolve in 15mol toluene, add DMP with 1% of the mass fraction -30 promoter, after stirring evenly, react at room temperature (30°C) for 2h, and obtain an epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com