Antibacterial master batch containing high-dispersity inorganic antibacterial agent, and preparation method thereof

A technology of inorganic antibacterial agent and antibacterial masterbatch, applied in the field of preparation of antibacterial masterbatch, can solve the problems of natural environment pollution, poor dispersibility of inorganic antibacterial agent, uneven content of antibacterial masterbatch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The following exemplifies the preparation method of the present invention.

[0057] Weigh the required number of raw materials, for example, if the mass of all raw materials is 100 parts, you can choose 60-90 parts of matrix resin, inorganic antibacterial agent: 1-30 parts, binder: 0.5-5 parts, dispersant: 0 ~5 servings. All raw materials are preferably dried and anhydrous treated in advance, for example by oven drying.

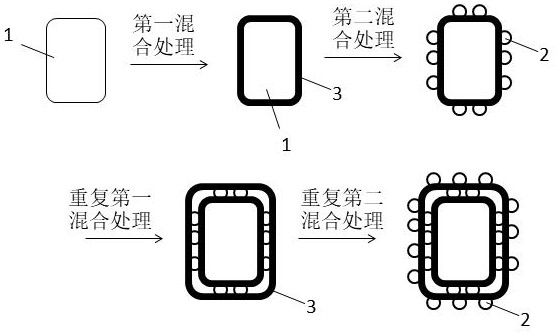

[0058]Firstly, the base resin and the binder are subjected to the first mixing treatment, so that the binder can spread on the surface of the base resin. The spreading described here refers to making the binder wet at least part of the base resin surface, preferably uniformly throughout the resin The surface spreads to form a binder layer. The first mixing process can be carried out at normal temperature using conventional mixing equipment (for example: low-speed mixer, high-speed mixer), the mixing speed is 30 to 3000 rpm, preferably 60 to 300 rpm, ...

Embodiment 1

[0079] Embodiment 1: preparation of polyamide 6 (PA6) antibacterial masterbatch

[0080] The first step: remove the moisture in the drying equipment for the required raw material matrix resin PA6, inorganic antibacterial agent nano-zinc oxide ZnO and dispersant polyethylene wax, and weigh the raw materials according to the following parts by mass: 87.5 parts of dried matrix resin PA6, 10 parts of dry inorganic antibacterial agent nano zinc oxide ZnO, 1 part of dry dispersant polyethylene wax.

[0081] Step 2: Mixing of matrix resin PA6 and binder anhydrous glycerin: Weigh the dried matrix resin PA6 and dispersant polyethylene wax, add 0.5 part of binder anhydrous glycerin, and mix evenly in a mixing device to obtain "The mixture of matrix resin and binder" is called "A particle". Mixing equipment speed: 150 rpm, mixing time 20 minutes.

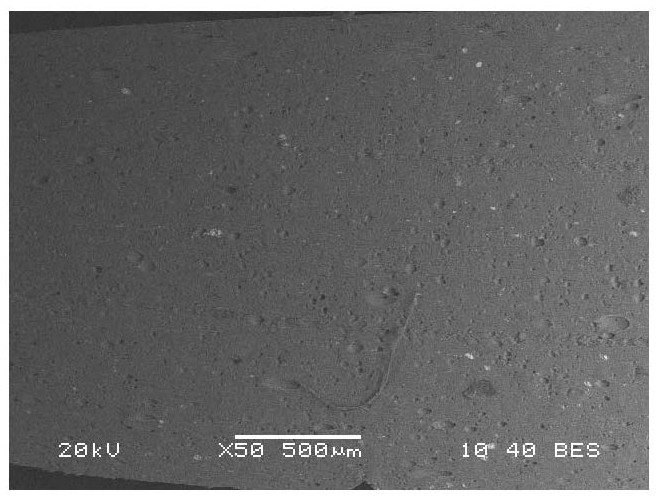

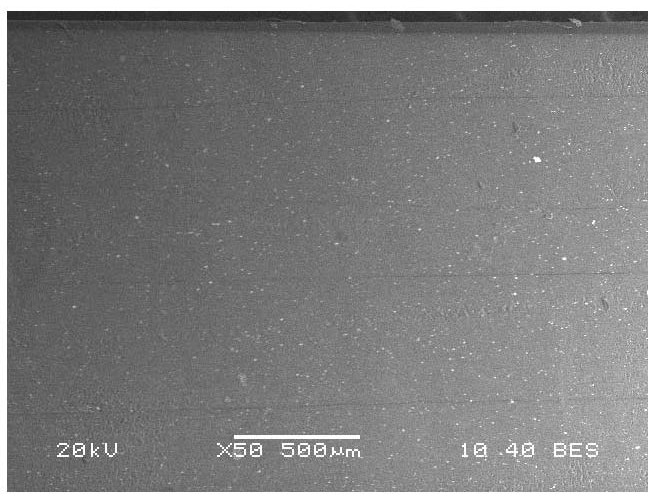

[0082] The third step: adding 5 parts of inorganic antibacterial agent nano-zinc oxide ZnO into the "mixture of matrix resin and binder" an...

Embodiment 2

[0086] Embodiment 2: preparation of polypropylene (PP) antibacterial masterbatch

[0087] The first step: the required raw material matrix resin PP, inorganic antibacterial agent nano-titanium dioxide TiO 2 and dispersant oxidized polyethylene wax to remove moisture in drying equipment, and take raw materials according to the following parts by mass: 80 parts of dry matrix resin PP, 15 parts of dry inorganic antibacterial agent nano-titanium dioxide TiO 2 , 1.5 parts dry dispersant oxidized polyethylene wax.

[0088] Step 2: Mixing of matrix resin PP and binder liquid paraffin (distillation temperature>300°C): Weigh the dried matrix resin PP and dispersant oxidized polyethylene wax, add binder liquid paraffin (distillation temperature >300°C) 2.0 parts, mixed uniformly in the mixing equipment to obtain "a mixture of matrix resin and binder", which is called "A particle". Mixing equipment speed: 150 rpm, mixing time 20 minutes.

[0089] The third step: 5 parts of inorganic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com