Preparation method of self-adhesive hydrogel material for DIW customized bolus

A hydrogel, self-adhesive technology, used in X-ray/γ-ray/particle irradiation therapy, etc., can solve the problems of air gap between bolus and skin, poor performance, etc., achieve fast rheological properties, good mechanical strength, inhibition The effect of air gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

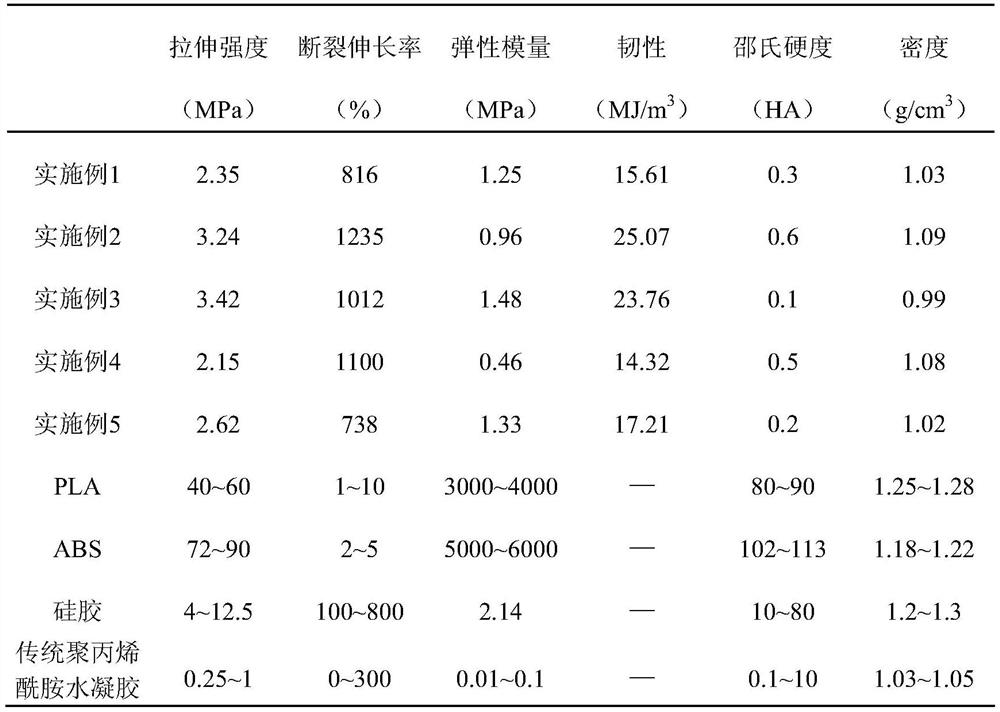

Examples

Embodiment 1

[0019] A method for preparing a self-adhesive hydrogel material for DIW custom bolus, comprising the following steps:

[0020] Step 1. Dissolve 0.2 g of dopamine hydrochloride powder in 100 ml of ammonia solution (pH=8-9), and then stir in the air for 20 minutes to form a pre-polymerized solution of dopamine;

[0021] Step 2. Dissolve 6g of sodium alginate and 20g of acrylic acid in the above-mentioned dopamine prepolymerization solution, adjust the pH of the solution to 7-8 with ammonia water, and then add 0.01g of cross-linking agent N,N'-methylenebisacrylamide (MBA) and 1g photoinitiator 2959, stirred for 2h to make the mixture uniform;

[0022] Step 3, add 1ml of Fe(NO 3 ) 3 aqueous solution, Fe(NO 3 ) 3 The dosage is 0.3g, vigorously stirred at room temperature for more than 5h, and then left to stand at 5°C for 48h to form a physically cross-linked gel preform, namely "gel ink";

[0023] Step 4. Use a wavelength of 365nm and an intensity of 8mW / cm at room temperatur...

Embodiment 2

[0026]A method for preparing a self-adhesive hydrogel material for DIW custom bolus, comprising the following steps:

[0027] Step 1. Dissolve 0.3 g of dopamine hydrochloride powder in 100 ml of ammonia solution (pH=8-9), and then stir in the air for 20 minutes to form a pre-polymerized solution of dopamine;

[0028] Step 2. Dissolve 5g of sodium alginate and 20g of acrylic acid in the above-mentioned dopamine prepolymerization solution, adjust the pH of the solution to 7-8 with ammonia water, and then add 0.02g of cross-linking agent N,N'-methylenebisacrylamide (MBA) and 2g photoinitiator 2959, stirred for 2h to make the mixed solution uniform;

[0029] Step 3, add 1ml of Fe(NO 3 ) 3 aqueous solution, Fe(NO 3 ) 3 The dosage is 0.4g, vigorously stirred at room temperature for more than 5h, and then left to stand at 5°C for 48h to form a physically cross-linked gel preform, namely "gel ink";

[0030] Step 4. Use a wavelength of 365nm and an intensity of 8mW / cm at room temp...

Embodiment 3

[0033] A method for preparing a self-adhesive hydrogel material for DIW custom bolus, comprising the following steps:

[0034] Step 1. Dissolve 0.32 g of dopamine hydrochloride powder in 80 ml of ammonia solution (pH=8-9), and then stir in the air for 20 minutes to form a pre-polymerized solution of dopamine;

[0035] Step 2. Dissolve 3g of sodium alginate and 16g of acrylic acid in the above-mentioned dopamine pre-polymerization solution, adjust the pH of the solution to 7-8 with ammonia water, and then add 0.003g of cross-linking agent N,N'-methylenebisacrylamide (MBA) and 0.32g photoinitiator 819, stir 2h to make the mixed solution uniform;

[0036] Step 3, add 1ml of Fe(NO 3 ) 3 aqueous solution, Fe(NO 3 ) 3 The dosage is 0.06g, vigorously stirred at room temperature for more than 5h, and then left to stand at 5°C for 48h to form a physically cross-linked gel preform, namely "gel ink";

[0037] Step 4. Use a wavelength of 365nm and an intensity of 8mW / cm at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com