Method for recovering copper sulfate in acidic copper sulfate waste liquid

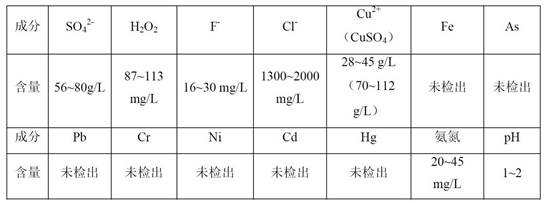

An acid copper sulfate, copper sulfate technology, applied in copper sulfate and other directions, can solve the problems of burning out the cathode, high treatment cost, small treatment capacity, etc., achieve uniform water volume and water quality, ensure process conditions, and reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

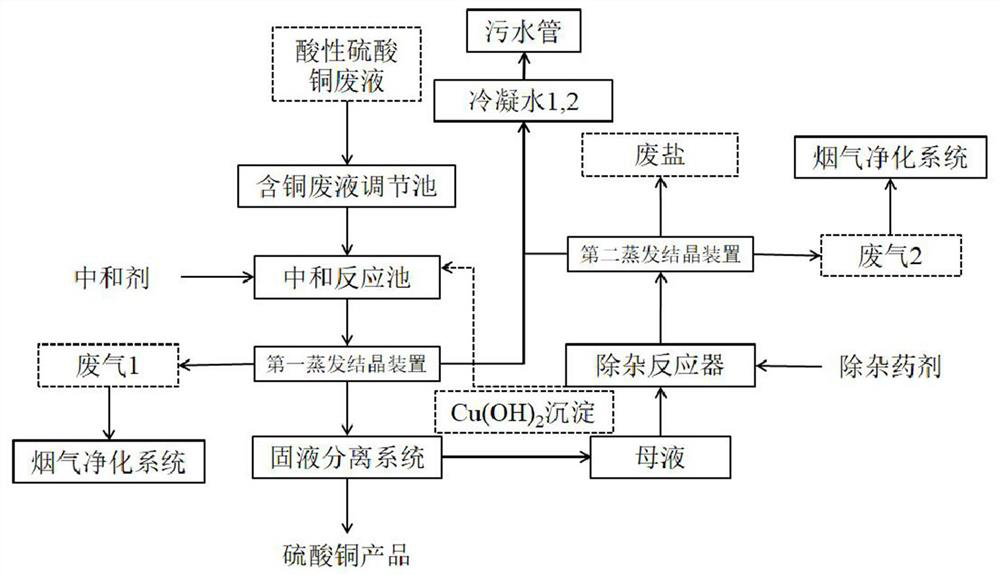

Method used

Image

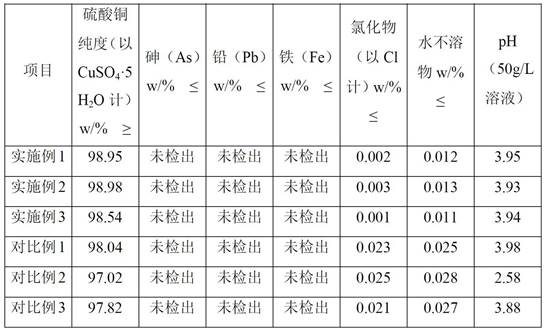

Examples

Embodiment 1

[0051] S1. Take 500L of acid copper sulfate waste liquid and collect it in the regulating tank to uniform water quantity and water quality;

[0052] S2. Pump the copper sulfate waste liquid with uniform water quality into the neutralization reaction tank, and add Cu(OH) 2 Powder to adjust pH to 3.56;

[0053] S3, pump the acid copper sulfate waste liquid after neutralization treatment in step S2 to the first evaporative crystallization device, evacuate the inside of the first evaporative crystallization device to -0.01MPa, and evaporate and crystallize for 2h under the condition that the temperature is 120 ℃ A solid-liquid mixture is obtained, the waste gas is discharged after being purified by the flue gas purification system, and the condensed water is discharged into the sewage pipe network;

[0054] S4, after the solid-liquid mixture after the evaporation and crystallization in step S3 is subjected to solid-liquid separation through a filter press, a plate filter or a cen...

Embodiment 2

[0058] S1. Take 500L of acid copper sulfate waste liquid and collect it in the regulating tank to uniform water quantity and water quality;

[0059] S2. Pump the copper sulfate waste liquid with uniform water quality into the neutralization reaction tank, and add Cu(OH) 2 Powder to adjust pH to 3.56;

[0060] S3, pump the acid copper sulfate waste liquid after neutralization treatment in step S2 to the first evaporation and crystallization device, evacuate the first evaporation device to -0.06MPa, and evaporate and crystallize at a temperature of 140 ° C for 3.5h A solid-liquid mixture is obtained, the waste gas is discharged after being purified by the flue gas purification system, and the condensed water is discharged into the sewage pipe network;

[0061] S4, after the liquid-solid mixture after the evaporation and crystallization in step S3 is subjected to solid-liquid separation by a filter press, a plate filter or a centrifuge, the obtained solid is naturally air-dried ...

Embodiment 3

[0065] S1. Take 500L of acid copper sulfate waste liquid and collect it in the regulating tank to uniform water quantity and water quality;

[0066] S2. Pump the copper sulfate waste liquid with uniform water quality into the neutralization reaction tank, and add Cu(OH) 2 Powder to adjust pH to 3.56;

[0067] S3, pump the acid copper sulfate waste liquid after neutralization treatment in step S2 to the first evaporative crystallization device, evacuate the first evaporative crystallization device to -0.09MPa, and evaporate and crystallize at a temperature of 160 ° C for 5h A solid-liquid mixture is obtained, the waste gas is discharged after being purified by the flue gas purification system, and the condensed water is discharged into the sewage pipe network;

[0068] S4, after the liquid-solid mixture after the evaporation and crystallization in step S3 is subjected to solid-liquid separation by a filter press, a plate filter or a centrifuge, the obtained solid is naturally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com