Method for preparing explosive composite tube in local vacuum environment through water pressure

A technology of partial vacuum and composite tubes, which is applied in welding equipment, manufacturing tools, non-electric welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

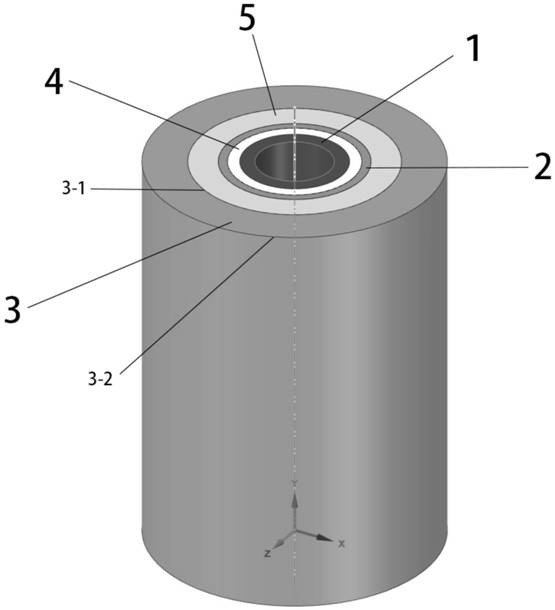

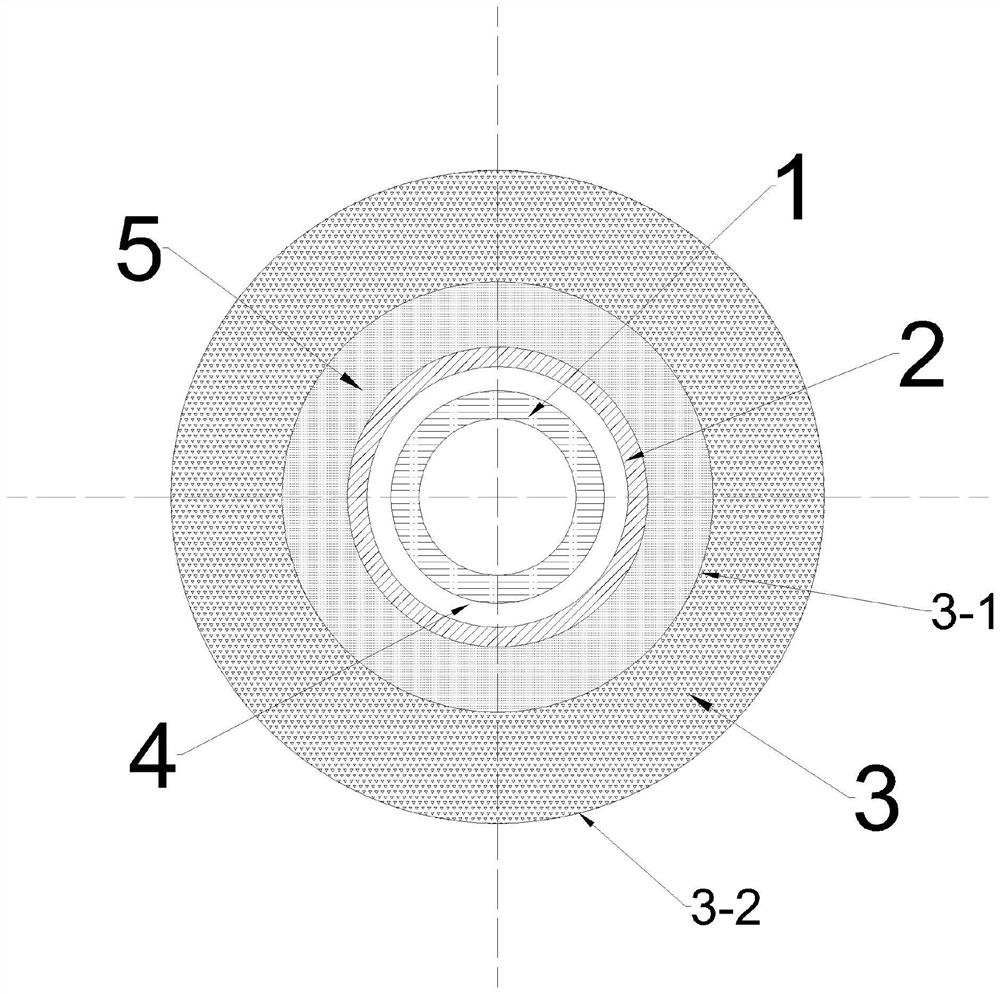

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Provided in conjunction with the accompanying drawings, a method for preparing an explosive composite pipe in a partial vacuum environment using water pressure comprises the following steps:

[0016] 1) From the inside to the outside, the pipe to be composited 1, the pipe to be composited 2, the small-sized PVC pipe 3-1, and the large-sized PVC pipe 3-2 are coaxially arranged between the PVC pipe 3-1 and the PVC pipe 3-2 Filling with explosives and detonators to form an explosive device 3;

[0017] 2) Seal and vacuum both ends of the gap between the pipe to be composited 1 and the pipe to be composited 2 with a sealing strip to construct a vacuum gap environment 4;

[0018] 3) Fill water between the pipe to be composited 2 and the explosive device to construct a water environment 5 .

[0019] 4) The detonation explosive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com