Beneficiation method for fine-grained disseminated copper ore in plateau area

A beneficiation method and regional technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of poor collector selectivity, difficult gradient separation and recovery, etc., and reduce the loss of copper and gold and silver minerals , Improve the effect of flotation mineralization foam and improve the quality of concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

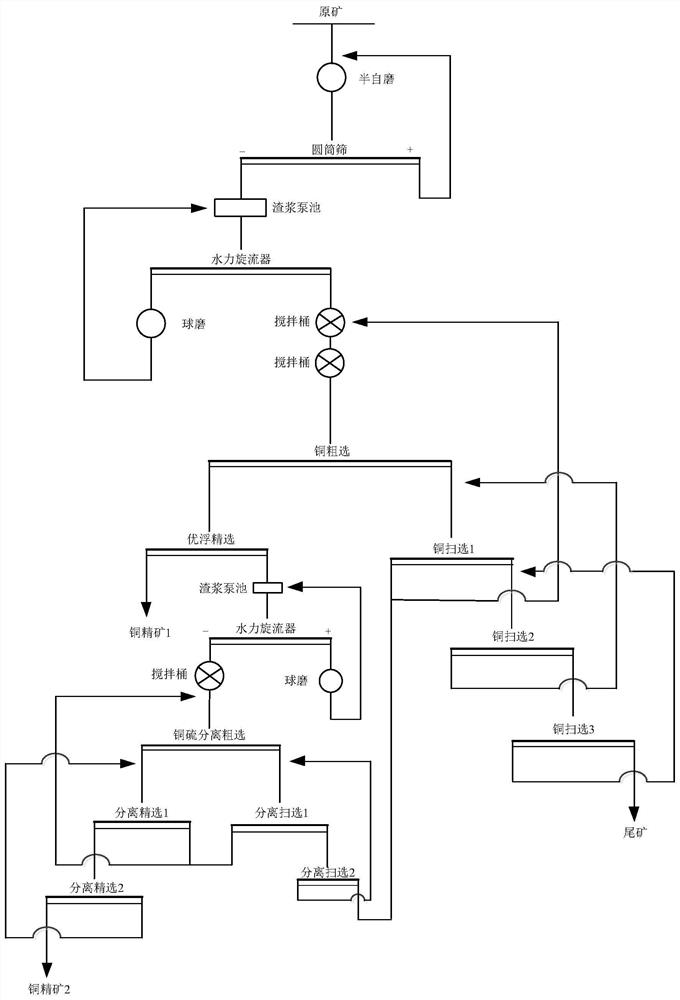

Method used

Image

Examples

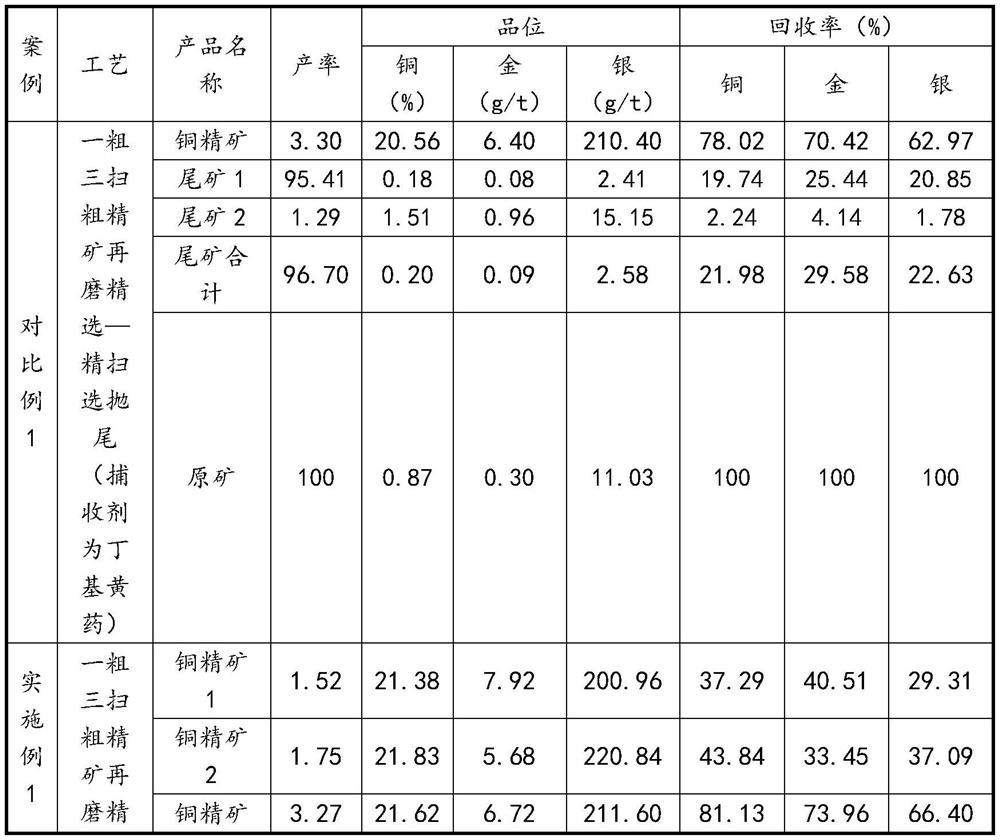

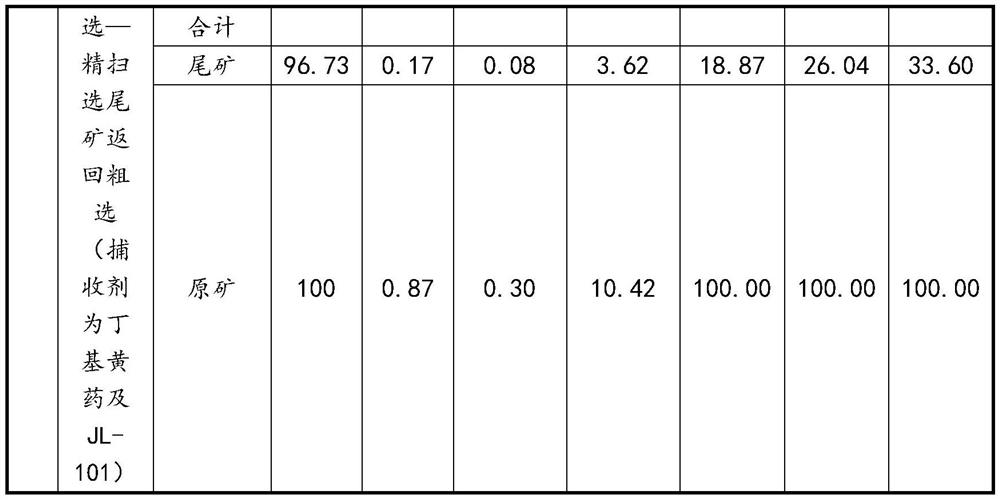

Embodiment 1

[0032] The ore selected in this embodiment is a skarn-type copper mine in Tibet. The raw ore contains 0.87% copper, 24.48% copper oxidation rate, 0.30g / t gold, and 11.03g / t silver. The main metal minerals in the ore are chalcopyrite, pyrite, a small amount of bornite, molybdenite, trace tetrahedrite, blue chalcocite, and the main gangue minerals are andandrite, epidote, quartz, etc. . Under the condition that the coarse grinding particle size -0.075mm accounts for 70%, the monomer dissociation degree of copper sulfide minerals is only 75.10%, and the proportion of fulian biophytes is 12.36%. Some copper minerals are finely embedded, and the current fineness Copper minerals have not been sufficiently dissociated.

[0033] This embodiment provides a kind of beneficiation method of fine-grained embedded copper ore in the plateau area. The above-mentioned copper ore is beneficiated, including the following steps:

[0034] S1, semi-autogenous grinding: the -120mm particle size ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com