A sorting method of difficult-to-float slime

A technology for slime and difficult-to-float, applied in flotation, solid separation and other directions, can solve the problems of low flotation recovery rate, difficult-to-float slime, and poor hydrophobicity of difficult-to-float slime, and achieves significant economic benefits and easy flotation. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

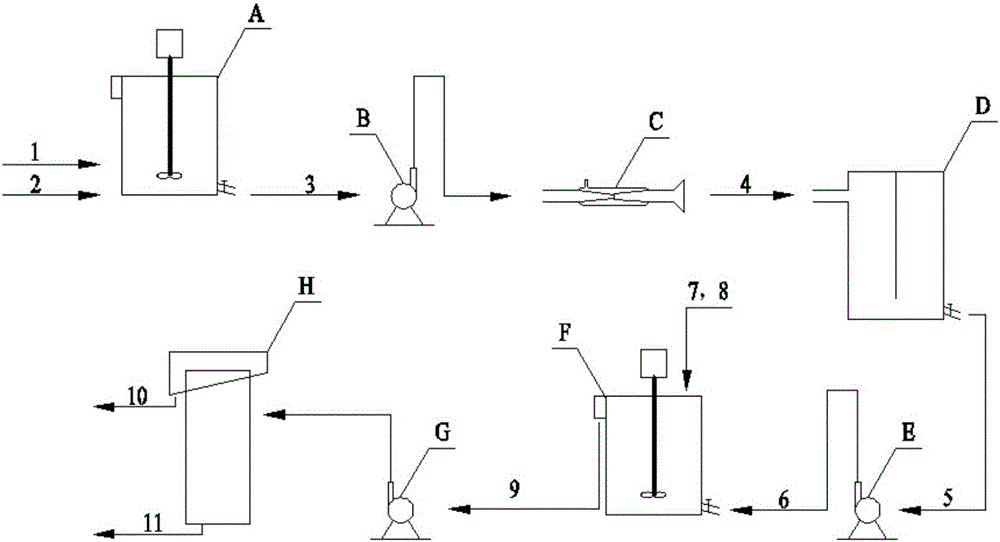

[0025] Such as figure 1 , water (2) and secondary octanol foaming agent (1) are fed into the mixing tank (A) and mixed, the proportioning of water and foaming agent is 0.07g foaming agent per liter of water, and the mixture after stirring (3 ) is fed into the Venturi tube (C) through the mixture feeding pump (B), the mixture dissolves air under the negative pressure generated by the jet and generates a large number of bubbles at the end of the Venturi tube (C), and the solution containing bubbles (4) is fed to the Venturi tube (C). Enter the upper part of the defoaming barrel (D), and a baffle is installed in the middle of the defoaming barrel (D), which divides it into two parts. (D) On the right side, the large air bubbles in the mixture rise to the upper part of the defoaming barrel under the action of buoyancy and gradually burst, so that the air bubbles generated by the Venturi tube (C) are removed after passing through the defoaming barrel (D), Leave the nano-bubbles in...

Embodiment 2

[0028] Such as figure 1 , put water (2) and 2-octanol (1) into the mixing tank (A) for mixing, the proportion of water and foaming agent is 0.033g foaming agent per liter of water, and the mixture (3) after stirring is passed through the mixture The feed pump (B) feeds into the Venturi tube (C), the mixture dissolves the air under the negative pressure generated by the jet and generates a large number of bubbles at the end of the Venturi tube (C), and the bubble-containing solution (4) is fed into the defoaming On the upper part of the barrel (D), a baffle plate is installed in the middle of the defoaming barrel (D), which divides it into two parts. The two parts of the barrel are only connected to the lower part. On the right, the large bubbles in the mixture rise to the upper part of the bubble removal tank under the action of buoyancy and gradually burst, so that the bubbles generated by the Venturi tube (C) pass through the bubble removal tank (D) and the large bubbles are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com