Calcium sulfide-based slow-release vulcanizing agent as well as preparation method and application thereof

A technology of calcium sulfide and vulcanizing agent, which is applied in the field of calcium sulfide-based slow-release vulcanizing agent, preparation of calcium sulfide-based slow-release vulcanizing agent, and slow-release vulcanizing agent. , secondary pollution and other issues, to avoid the generation of harmful hydrogen sulfide gas, which is conducive to large-scale production and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The concentration of arsenic in the sewage acid of a lead-zinc smelter in Hunan is 2g / L, the concentration of zinc ions is 0.7g / L, the concentration of lead ions is 100mg / L, and the concentration of copper ions is 60mg / L.

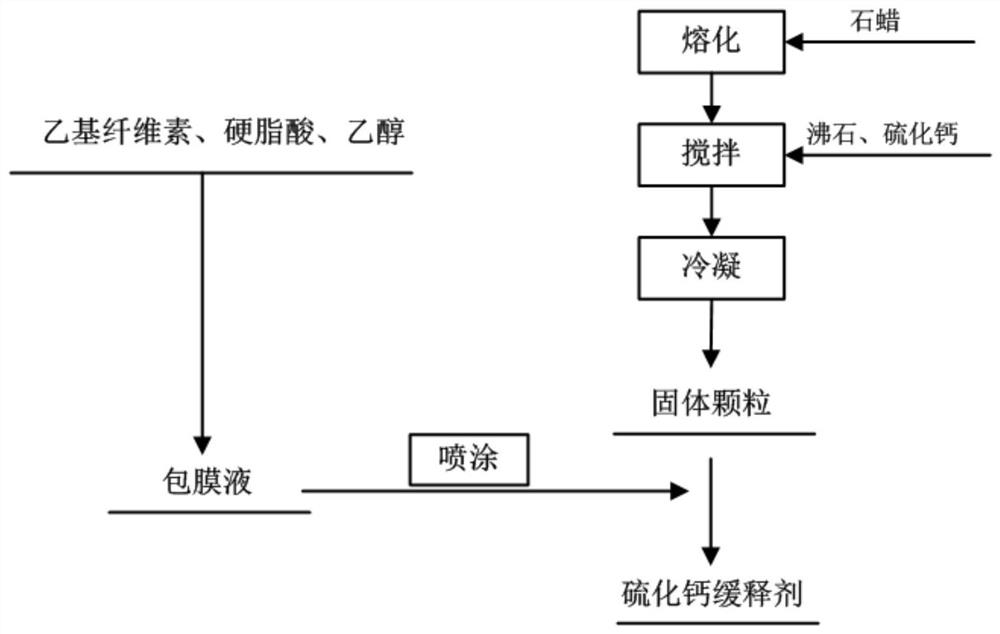

[0029] First, melt the paraffin wax at 70°C, then add calcium sulfide and zeolite according to the mass ratio of paraffin wax, zeolite and calcium sulfide 1.5:3:5.5, stir for 20 minutes, pour into a mold for condensation. Ethyl cellulose and stearic acid were fully dissolved in a small amount of ethanol according to the mass percentage of 8% and 3% respectively to prepare a uniform coating solution. The coating solution is evenly sprayed on the surface of the condensed solid particles to obtain the calcium sulfide slow-release agent. Add the calcium sulfide slow-release agent into the acidic solution, the added calcium sulfide slow-release agent is 1.1 times the theoretical amount, stir for 40 minutes, and control the reaction temperature at 45°C. Af...

Embodiment 2

[0041] The concentration of arsenic in the sewage acid of a zinc smelter in Hunan is 30.3mg / L, the concentration of zinc ions is 450mg / L, the concentration of cadmium ions is 30.6mg / L, and the concentration of copper ions is 4.7mg / L.

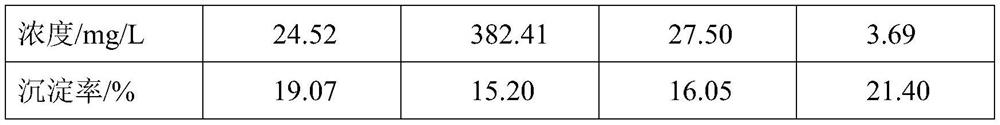

[0042] first. Melt the paraffin wax at 70°C, then add calcium sulfide and zeolite according to the mass ratio of paraffin wax, zeolite and calcium sulfide 1.5:3.5:5, stir for 20 minutes, pour into a mold for condensation. In addition, ethyl cellulose and stearic acid were fully dissolved in ethanol according to the addition amount of 10% and 4% by mass respectively to prepare a uniform coating solution. The coating solution is evenly sprayed on the surface of the condensed solid particles to obtain the calcium sulfide slow-release agent. Add the calcium sulfide slow-release agent to the sewage acid, the added calcium sulfide slow-release agent is 1.15 times the theoretical amount, stir and react for 40 minutes, the reaction temperature is contr...

Embodiment 3

[0055] The concentration of arsenic in the sewage acid of a zinc smelter in Hunan is 45.3mg / L, the concentration of zinc ions is 330mg / L, the concentration of lead ions is 22mg / L, and the concentration of copper ions is 8.0mg / L.

[0056] first. Melt the paraffin wax at 70°C, then add calcium sulfide and zeolite according to the mass ratio of paraffin wax, zeolite and calcium sulfide 1:3:6, stir for 25 minutes, pour into a mold for condensation. In addition, ethyl cellulose and stearic acid were fully dissolved in ethanol according to the addition amount of 10% and 4% by mass respectively to prepare a uniform coating solution. The coating solution is evenly sprayed on the surface of the condensed solid particles to obtain the calcium sulfide slow-release agent. Add the calcium sulfide slow-release agent to the sewage acid, the added calcium sulfide slow-release agent is 1.2 times the theoretical amount, stir and react for 45 minutes, the reaction temperature is controlled at 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com