Composite 3D printing material containing coffee grounds as well as preparation method and application of composite 3D printing material

A 3D printing and coffee grounds technology, applied in the field of additive manufacturing, can solve problems such as clogged nozzle printing, materials that cannot be printed, failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

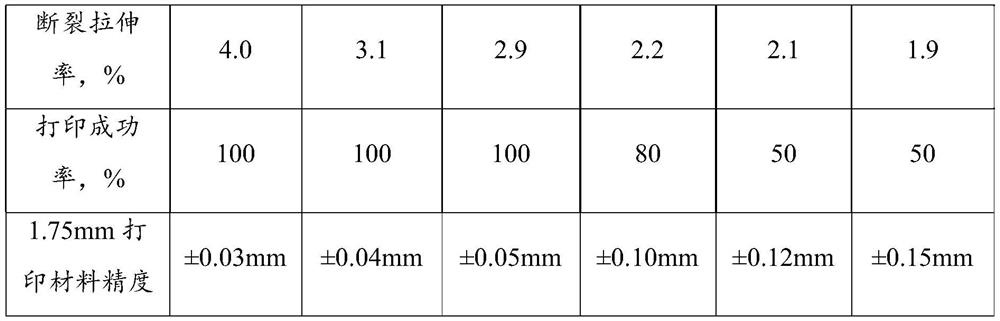

Examples

Embodiment 1

[0035] The composite 3D printing material of this embodiment is made of the following raw materials in parts by weight: 20 parts of modified coffee grounds, 80 parts of polylactic acid, 3 parts of polycaprolactone, 20 parts of polyhydroxyalkanoate and 2 parts of plasticizer ; Wherein, the modified coffee grounds is obtained by modifying the coffee grounds raw material with a mixed solution containing water-soluble polyester and coupling agent, and the water-soluble polyester includes the first water-soluble polyester (purchased from Henan Xingguang Resin Co., Ltd. ) and the second water-soluble polyester (Korean water-soluble polyester SK375), the coupling agent is a titanate coupling agent, and the plasticizer is DOP.

[0036] The preparation steps of the above composite 3D printing materials are as follows:

[0037] 1. Coffee grounds pretreatment

[0038]Screen the collected coffee grounds to remove impurities such as non-coffee grounds, and then use vacuum equipment for pr...

Embodiment 2

[0046] The composite 3D printing material of this embodiment is made of the following raw materials in parts by weight: 35 parts of modified coffee grounds, 65 parts of polylactic acid, 2 parts of polycaprolactone, 15 parts of polyhydroxyalkanoate and 1 part of plasticizer Among them, the modified coffee grounds are obtained by modifying the raw material of coffee grounds with a mixed solution containing water-soluble polyester and a coupling agent, the water-soluble polyester is water-soluble polyester SK375, and the coupling agent is titanate coupling agent, the plasticizer is DOP.

[0047] The preparation steps of the above composite 3D printing materials are as follows:

[0048] 1. Coffee grounds pretreatment

[0049] Screen the collected coffee grounds to remove impurities such as non-coffee grounds, and then use vacuum equipment for preliminary drying; mix the dried coffee grounds evenly, and then use a grinder to grind the coffee grounds into powder, with a particle si...

Embodiment 3

[0057] The composite 3D printing material of this embodiment is made of the following raw materials in parts by weight: 45 parts of modified coffee grounds, 55 parts of polylactic acid, 4 parts of polycaprolactone, 25 parts of polyhydroxyalkanoate and 3 parts of plasticizer Among them, the modified coffee grounds are obtained by modifying the raw material of coffee grounds with a mixed solution containing water-soluble polyester and coupling agent. The water-soluble polyester is purchased from Henan Xingguang Resin Co., Ltd., and the coupling agent is silane coupling Agent KH570, the plasticizer is epoxy soybean oil.

[0058] The preparation steps of the above composite 3D printing materials are as follows:

[0059] 1. Coffee grounds pretreatment

[0060] Screen the collected coffee grounds to remove impurities such as non-coffee grounds, and then use vacuum equipment for preliminary drying; mix the dried coffee grounds evenly, and then use a grinder to grind the coffee groun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com