Mildew-proof bamboo plywood and preparation method thereof

A bamboo plywood, anti-mildew technology, applied in the direction of adhesives, mechanical equipment, manufacturing tools, etc., can solve the problems of reduced value, decay, moth-eaten, affecting use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

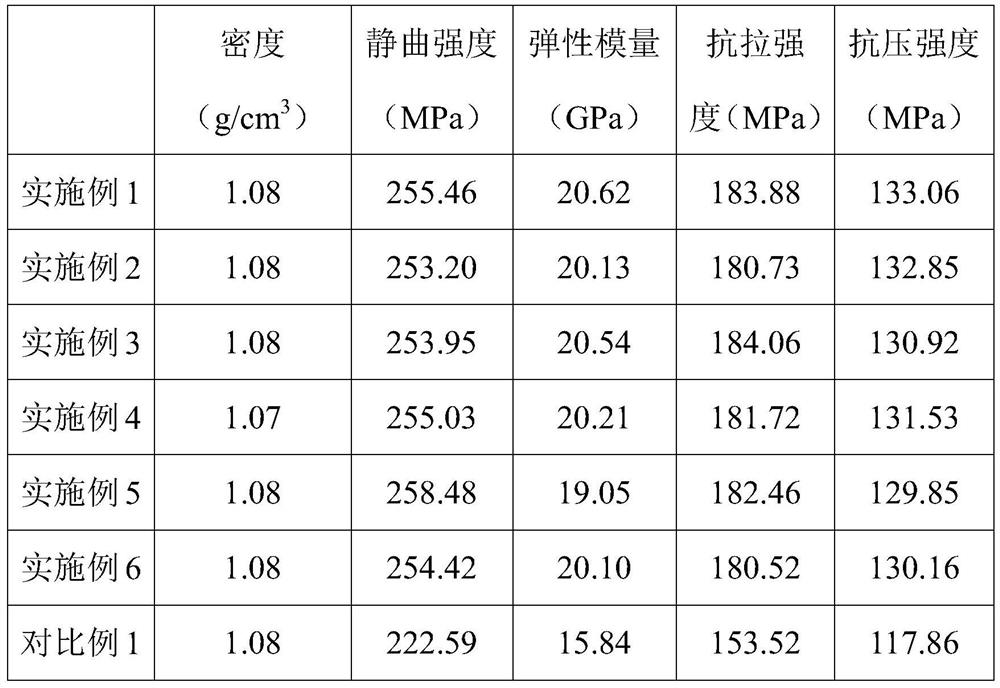

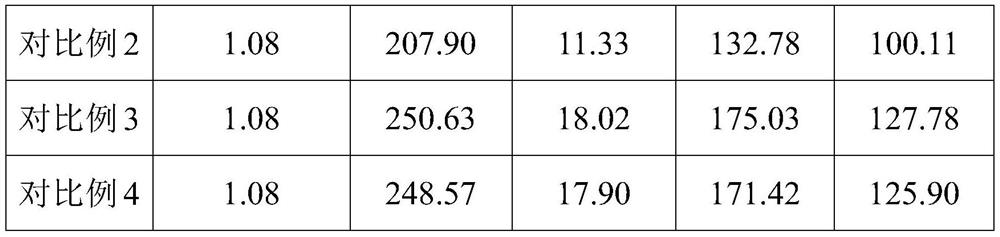

Examples

Embodiment 1

[0027] A process for preparing mold-type Plywood:

[0028] The transverse bamboo into bamboo section, milled to an outer vertical sectional holiday, then go to the milling section, added to the sodium hydroxide, thiourea, sodium sulfamate mass ratio of 5: 5: 1 complex concentration of 8% by mass after the aqueous solution was heated to 50 deg.] C cooking 60min, extracted with water to neutral, dried to a moisture content of 15%, obtained after 5 ease bamboo veneer, bamboo veneer is added to the adhesive immersion treatment 10min, remove and drain gum solution, which was dried to a moisture content of 8% or less by weight of the adhesive parts from the raw material composition: 60 parts of phenol resin, 30 parts of o-cresol formaldehyde epoxy resin, aqueous polyurethane emulsion of 30 parts, 10 parts nanoclays , 1 part of glyceryl tristearate, trimethyl hexamethylene diamine, 1 part of dibutyl sebacate, 1 part of 2 parts of modified halloysite nanotube load fungicide, 50 parts of p...

Embodiment 2

[0030] A process for preparing mold-type Plywood:

[0031] The transverse bamboo into bamboo section, milled to an outer vertical sectional holiday, then go to the milling section, added to the sodium hydroxide, thiourea, sodium sulfamate mass ratio of 6: 10: 1 complex concentration of 8% by mass after the aqueous solution was heated to 50 deg.] C cooking 50min, extracted with water to neutral, dried to a moisture content of 12%, 7 to give the ease of bamboo veneer, bamboo veneer is added to the adhesive immersion treatment 20min, remove and drain gum solution, which was dried to a moisture content of 8% or less by weight of the adhesive parts from the raw material composition: 50 parts of phenol resin, 20 parts of o-cresol-formaldehyde epoxy resin, aqueous polyurethane emulsion of 20 parts, 10 parts nanoclays , 2 parts of glyceryl tristearate, trimethyl hexamethylene diamine, 0.5 parts, 1 part of dibutyl sebacate, 2 parts of modified halloysite nanotube load fungicide, 50 parts o...

Embodiment 3

[0033] A process for preparing mold-type Plywood:

[0034]The transverse bamboo into bamboo section, milled to an outer vertical sectional holiday, then go to the milling section, added to the sodium hydroxide, thiourea, sodium sulfamate mass ratio 4: 5: 1 complex concentration of 8% by mass after the aqueous solution was heated to 50 deg.] C cooking 40min, extracted with water to neutral, dried to a moisture content of 10%, three times to give ease bamboo veneer, bamboo veneer is added to the adhesive immersion treatment 10min, remove and drain gum solution, which was dried to a moisture content of 5% or less by weight of the adhesive parts from the raw material composition: 50 parts of phenol resin, 20 parts of o-cresol-formaldehyde epoxy resin, aqueous polyurethane emulsion of 20 parts, 5 parts nanoclays , 1 part of glyceryl tristearate, 0.1 parts of trimethyl hexamethylene diamine, dibutyl sebacate, 1 part of 2 parts of modified halloysite nanotube load fungicide, 40 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com