Alkaline secondary battery and preparation method thereof

A secondary battery, alkaline technology, applied in the direction of alkaline storage battery, alkaline storage battery electrode, battery electrode, etc., can solve the problem that the discharge specific capacity of the secondary battery is easy to drop, and improve the electrochemical reversibility and increase the rate performance , Increase the effect of electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] This specific embodiment also proposes a preparation method of the above-mentioned alkaline secondary battery, comprising the following steps:

[0037] Assemble according to the order of positive electrode casing, steel mesh, positive electrode, separator, negative electrode, steel mesh, and negative electrode casing, and add alkaline aqueous electrolyte to obtain the alkaline secondary battery; the separator is glass fiber diaphragm, nylon fiber diaphragm, polypropylene fiber Diaphragm, Velen fiber membrane or filter paper;

[0038] Wherein, the boride in the negative electrode is made by the following steps:

[0039] dissolving the metal salt in water, cooling in an ice-water bath to obtain a metal salt solution, then dissolving borohydride in an alkaline aqueous solution with a pH value of 10-14, and then adding it dropwise to the metal salt solution to obtain the boron compound, and the boride is placed in a vacuum oven and dried at 50-120°C for 1-24h; the metal sa...

Embodiment 1

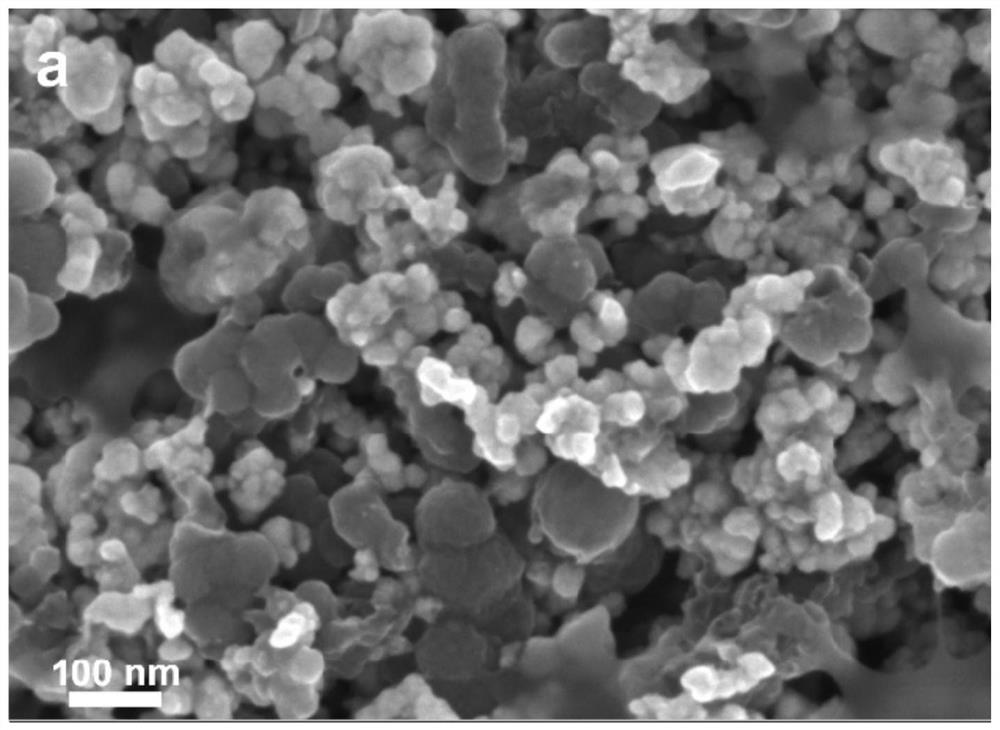

[0046] Prepare the active material cobalt boride in the negative electrode:

[0047] Dissolve sodium borohydride in aqueous sodium hydroxide solution with a pH value of 12 to prepare 250 mL of 0.5 mol L -1 The sodium borohydride solution, the purpose of adding sodium hydroxide is to prevent the violent hydrolysis of sodium borohydride;

[0048] Prepare divalent cobalt chloride solution (0.1mol L -1 ,250mL), then cooled in an ice bath, and with stirring, the sodium borohydride solution was added dropwise to the CoCl 2 Carry out chemical reduction reaction in the solution to obtain cobalt boride precipitate; after the addition is completed, continue to stir for about 1 hour to release hydrogen.

[0049] The cobalt boride precipitate was first washed with distilled water to remove the reaction residue, and then washed with ethanol to prevent further oxidation of the sample surface. Finally, the sample was dried in a vacuum at 80°C for 14 hours to remove residual water and etha...

Embodiment 2

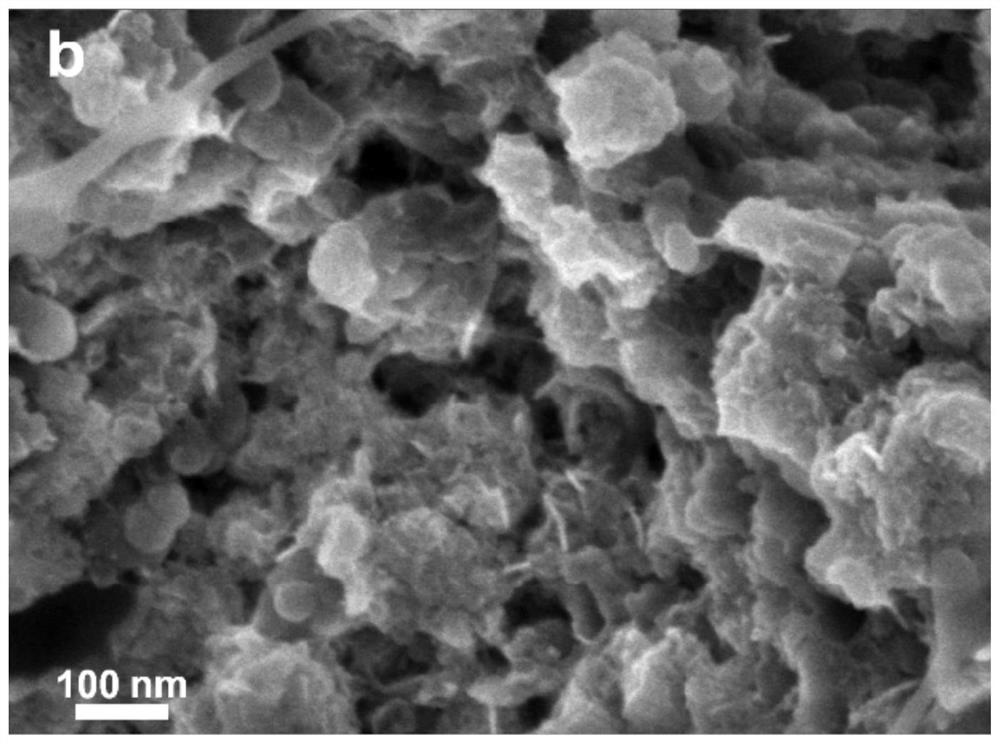

[0054] Prepare the active material cobalt boride in the negative electrode:

[0055] Dissolve potassium borohydride in aqueous potassium hydroxide solution with a pH value of 14 to prepare 250 mL of 0.5 mol L -1 Potassium borohydride solution, the purpose of adding potassium hydroxide is to prevent the violent hydrolysis of potassium borohydride;

[0056] Prepare divalent cobalt chloride solution (0.1mol L -1 , 250mL), then cooled in an ice bath, and under stirring conditions, the potassium borohydride solution was added dropwise to the cobalt sulfate solution to carry out chemical reduction reaction to obtain cobalt boride precipitation; after the addition was completed, continue stirring for about 1h, release hydrogen.

[0057] The cobalt boride precipitate was first washed with distilled water to remove the reaction residue, and then washed with ethanol to prevent further oxidation of the sample surface. Finally, the sample was dried in a vacuum at 50°C for 24 hours to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com