High-nickel ternary lithium ion battery positive electrode material and preparation method thereof

A lithium-ion battery and cathode material technology, applied in the field of high-nickel ternary lithium-ion battery cathode materials and its preparation, can solve the problems of reduced working voltage, poor cycle performance and poor rate performance of high-nickel ternary materials, and achieve enhanced Stability, improving electrochemical kinetic performance, and improving the effect of rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh reactants such as 0.01mol lithium chloride, 0.009mol nickel nitrate, 0.0005mol cobalt nitrate, 0.0005mol scandium nitrate and 0.02mol citric acid, put them all into a 200mL beaker, add 100mL distilled water, and then The beaker was moved to a water bath at 80°C, and reacted while stirring until a gel was formed.

[0023] (2) Dry the gel obtained in step (1), then transfer the dried gel to a muffle furnace, heat to 800°C at a heating rate of 5°C / min and keep the temperature constant for 6 hours, and then cool naturally, Get LiNi 0.9 co 0.05 sc 0.05 o 2 . figure 1 is the X-ray diffraction pattern of the material.

[0024] The prepared lithium ion battery cathode material LiNi 0.9 co 0.05 sc 0.05 o 2 , acetylene black and PVDF are ground and mixed evenly at a mass ratio of 8:1:1, and an appropriate amount of NMP is added dropwise to make electrode slurry, and then the slurry is evenly coated on aluminum foil, and placed in a vacuum oven at 120°C Fully d...

Embodiment 2

[0026] (1) Weigh 0.01mol lithium nitrate, 0.0087mol nickel nitrate, 0.0005mol cobalt nitrate, 0.0008mol scandium nitrate and 0.02mol tartaric acid and other reactants, put them all into a 200mL beaker, add 100mL distilled water, and then transfer the beaker to In a water bath at 80°C, react while stirring until a gel is formed.

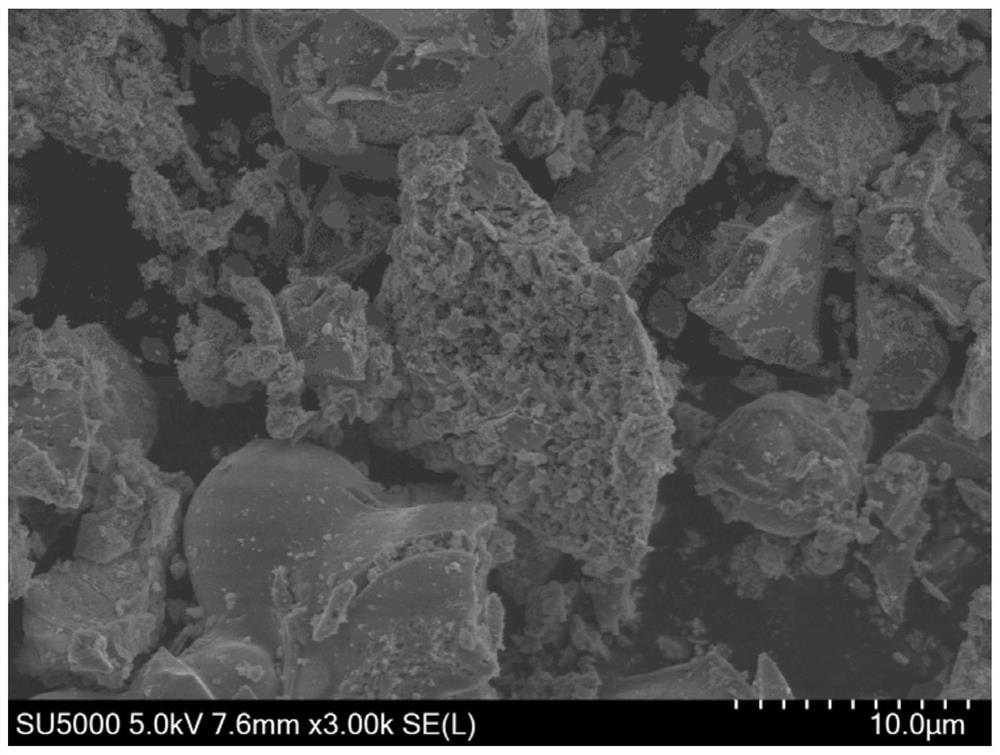

[0027] (2) Dry the gel obtained in step (1), then transfer the dried gel to a muffle furnace, heat to 800°C at a heating rate of 5°C / min and keep the temperature constant for 6 hours, and then cool naturally, Get LiNi 0.87 co 0.05 sc 0.08 o 2 . figure 2 is the X-ray diffraction pattern of the material. image 3 A scanning electron microscope image of the material.

[0028] The prepared lithium ion battery cathode material LiNi 0.87 co 0.05 sc 0.08 o 2 , acetylene black and PVDF are ground and mixed evenly at a mass ratio of 8:1:1, and an appropriate amount of NMP is added dropwise to make electrode slurry, and then the slurry is evenly coat...

Embodiment 3

[0030] (1) Take reactants such as 0.015mol lithium chloride, 0.01275mol nickel chloride, 0.0015mol cobalt nitrate, 0.00075mol scandium nitrate and 0.03mol citric acid, put it all into a 200mL beaker, add 120mL distilled water, and then Move the beaker to a water bath at 80°C and react while stirring until the gel is formed.

[0031] (2) Dry the gel obtained in step (1), then transfer the dried gel to a muffle furnace, heat to 800°C at a heating rate of 5°C / min and keep the temperature constant for 6 hours, and then cool naturally, Get LiNi 0.85 co 0.1 sc 0.05 o 2 .

[0032] The prepared lithium ion battery cathode material LiNi 0.85 co 0.1 sc 0.05 o 2 , acetylene black and PVDF are ground and mixed evenly at a mass ratio of 8:1:1, and an appropriate amount of NMP is added dropwise to make electrode slurry, and then the slurry is evenly coated on aluminum foil, and placed in a vacuum oven at 120°C Fully dry in the medium, cut into a foil with a diameter of 15mm as the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com