A kind of preparation method and application of in-situ growth nano calcium carbonate hydrogel sponge marine antifouling material

A nano-calcium carbonate and marine antifouling technology, applied in antifouling/underwater coatings, biocide-containing paints, etc., can solve the problems of disappearing antifouling interface, poor mechanical properties of hydrogel, and increased mechanical properties, achieving Great application prospects, low surface performance, and the effect of increasing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

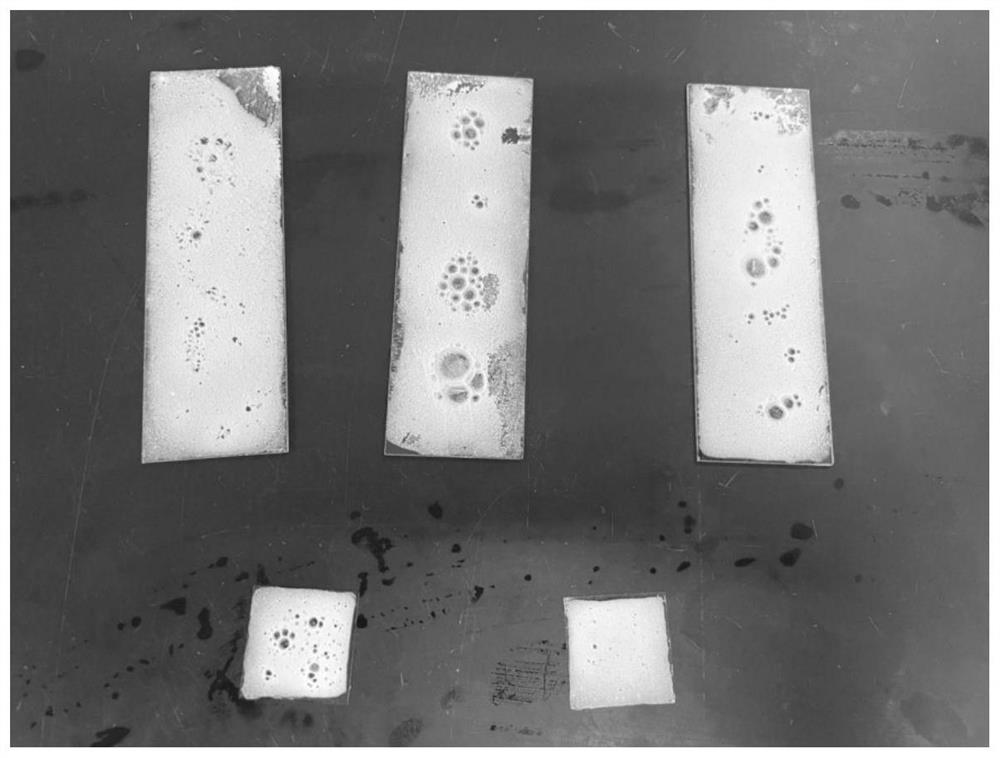

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 nano calcium carbonate hydrogel sponge

[0037] 1. Quaternized chitin: 1 g of chitin powder is dispersed in 50 mL (6.38wt% Ca(OH) 2 / 8.82wt%Na 2 CO 3 / 3.39wt% urea) solution, freeze and thaw twice at -40°C within 36h to obtain a white paste mixed solution of 2wt% chitin and nano-calcium carbonate. 6.705g of 2,3-epoxypropyltrimethylammonium chloride (EPTMAC) was added to the above chitin solution, and stirred at 10°C for 24h to obtain a paste-like white mixture, which is the grafted quaternary ammonium salt functional group. Semi-finished hydrogel;

[0038] 2. Hydrogel cross-linking: add 1877 type PVA (polyvinyl alcohol), PVA accounts for 10wt% of the total, after mixing evenly, the PVA is dissolved in the casting mold, the sample is placed at -20 ° C, frozen for 12 hours, the sample is taken out, and the temperature is room temperature. After thawing for 12 h, the above freezing and thawing process was repeated three times to obtain a...

Embodiment 2

[0039] The preparation of embodiment 2 nano calcium carbonate hydrogel sponge

[0040] 1. Quaternized chitin: 1 g of chitin powder is dispersed in 50 mL (5wt% Ca(OH) 2 / 12wt%Na 2 CO 3 / 2wt% urea) solution, freeze and thaw twice at -40°C within 36h to obtain a white paste mixed solution of 2wt% chitin and nano-calcium carbonate. Add 6.705 g of dimethyl diallyl ammonium chloride to the above chitin solution, and stir at 10°C for 24 hours to obtain a paste-like white mixture, which is a semi-finished hydrogel grafted with quaternary ammonium salt functional groups;

[0041] 2. Hydrogel cross-linking: add 1877 type PVA (polyvinyl alcohol), PVA accounts for 10wt% of the total, after mixing evenly, the PVA is dissolved in the casting mold, the sample is placed at -20 ° C, frozen for 12 hours, the sample is taken out, and the temperature is room temperature. After thawing for 12 h, the above freezing and thawing process was repeated three times to obtain a hydrogel physically cros...

Embodiment 3

[0042] The preparation of embodiment 3 nanometer calcium carbonate hydrogel sponge

[0043] 1. Quaternized chitin: 1 g of chitin powder is dispersed in 50 mL (10wt% Ca(OH) 2 / 7wt%Na 2 CO 3 / 6wt% urea) solution, freeze and thaw twice at -40°C within 36h to obtain a white paste mixed solution of 2wt% chitin and nano-calcium carbonate. 6.705 g of glycidyl trimethyl ammonium chloride was added to the above chitin solution, and stirred at 10° C. for 24 hours to obtain a paste-like white mixture, which is a semi-finished hydrogel with quaternary ammonium salt functional groups grafted;

[0044] 2. Hydrogel cross-linking: add 1877 type PVA (polyvinyl alcohol), PVA accounts for 10wt% of the total, after mixing evenly, the PVA is dissolved in the casting mold, the sample is placed at -20 ° C, frozen for 12 hours, the sample is taken out, and the temperature is room temperature. After thawing for 12 h, the above freezing and thawing process was repeated three times to obtain a hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com