Shiitake mushroom crushing device and use method thereof

A crushing device and shiitake mushroom technology, which is applied in the field of shiitake mushroom processing, can solve the problems that the quality of shiitake mushroom powder cannot meet the requirements, the shiitake mushrooms are not very fine, and it is not conducive to the long-term development of enterprises, so as to achieve the effects of improving quality, not easy to accumulate, and speeding up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

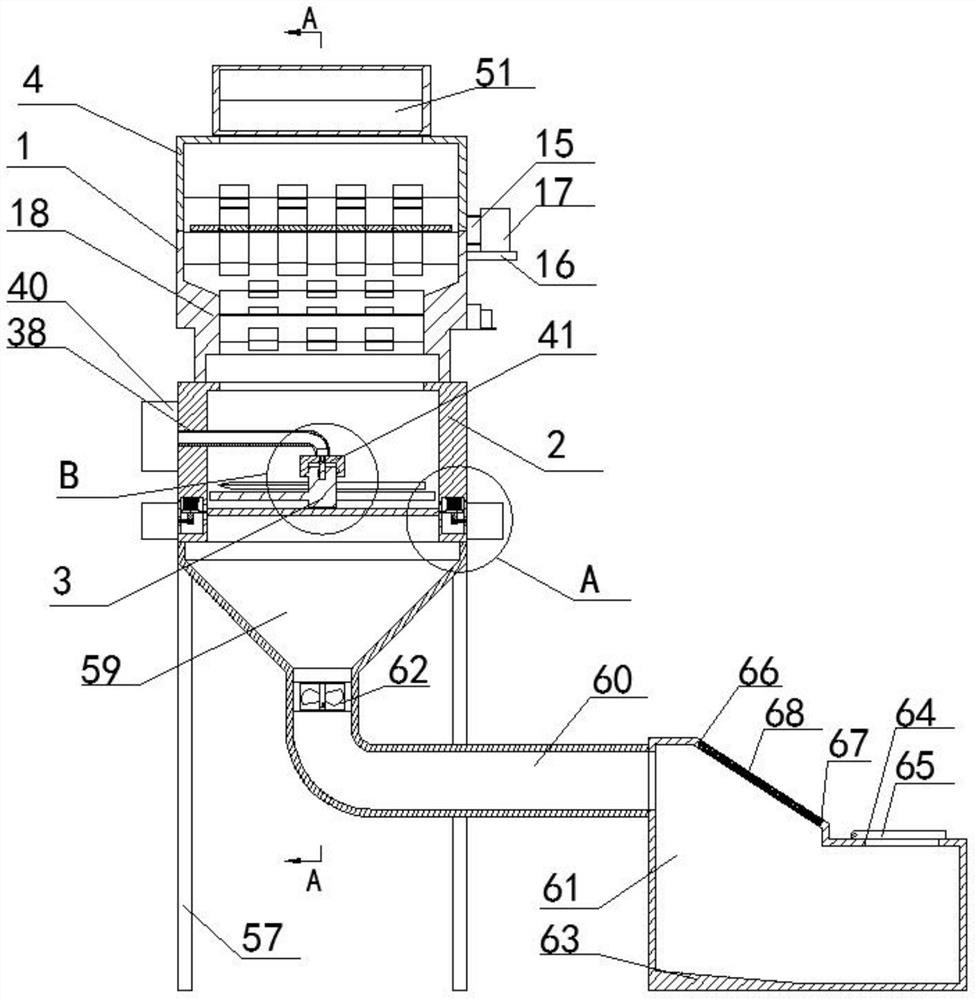

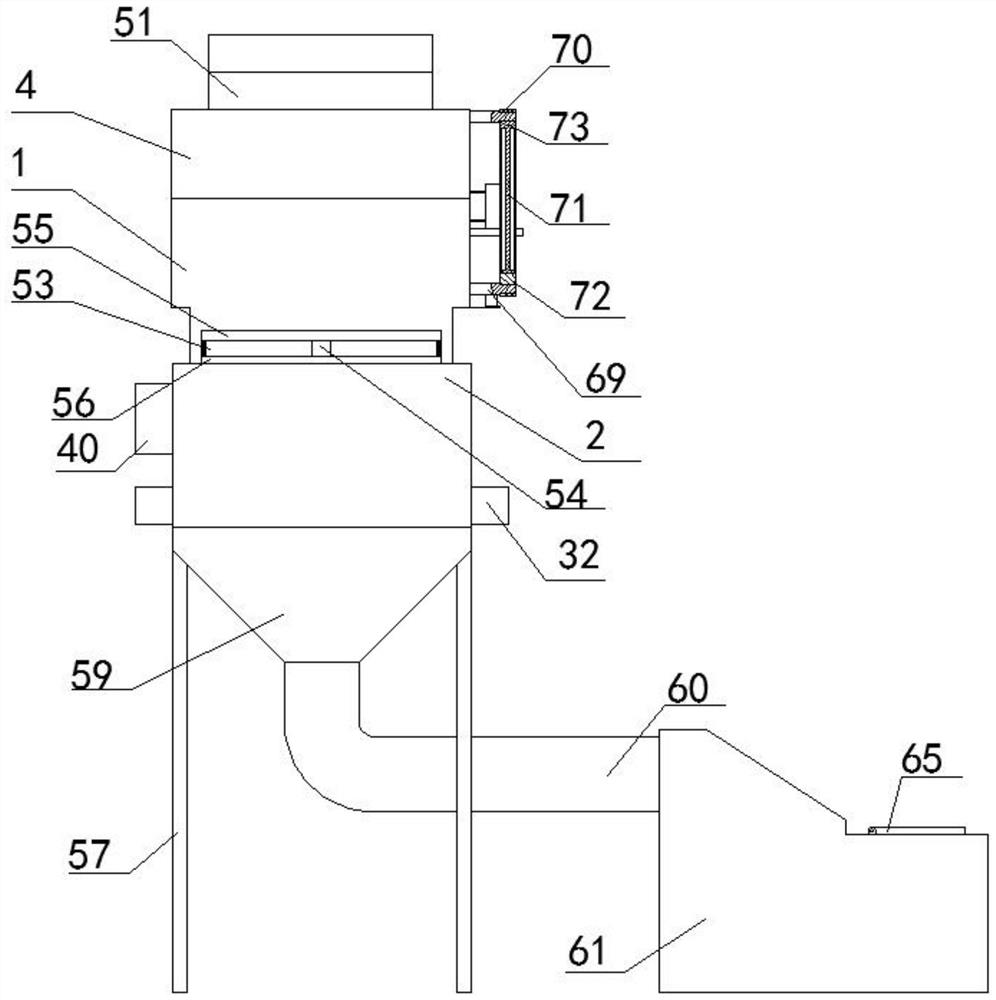

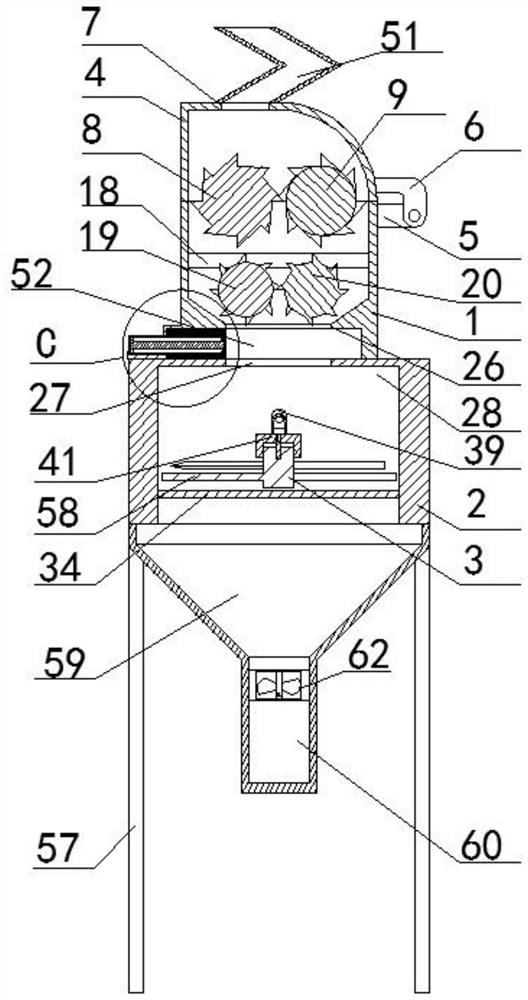

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] Refer to attached Figure 1-10 Shown: a shiitake mushroom crushing device, including a crushing box 1, a crushing box 2 and a rotary knife 3, a crushing box cover 4 is installed on the upper end of the crushing box 1, and the left and right sides of the rear upper end of the crushing box 1 are provided with box connections Block 5, the left and right ends of the rear lower end of the broken box cover 4 are provided with box cover connecting blocks 6 corresponding to the box body connecting block 5, the box body connecting block 5 and the box cover connecting block 6 are rotationally connected by short pins, and the broken box cover 4 The upper end is provided with a first feed opening groove 7, the upper end front side of the crushing box 1 is rotatably connected with a first crushing wheel 8, and the upper end rear side of the crushing box 1 is rotatably connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com