Corrugated steel plate and UHPC combined fabricated tunnel lining structure and construction method thereof

A corrugated steel plate and prefabricated technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of difficult construction quality assurance, tunnel freezing damage, and numerous construction procedures, so as to improve construction efficiency and service life, save support materials and labor force and the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned features and advantages of the present invention easier to understand, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

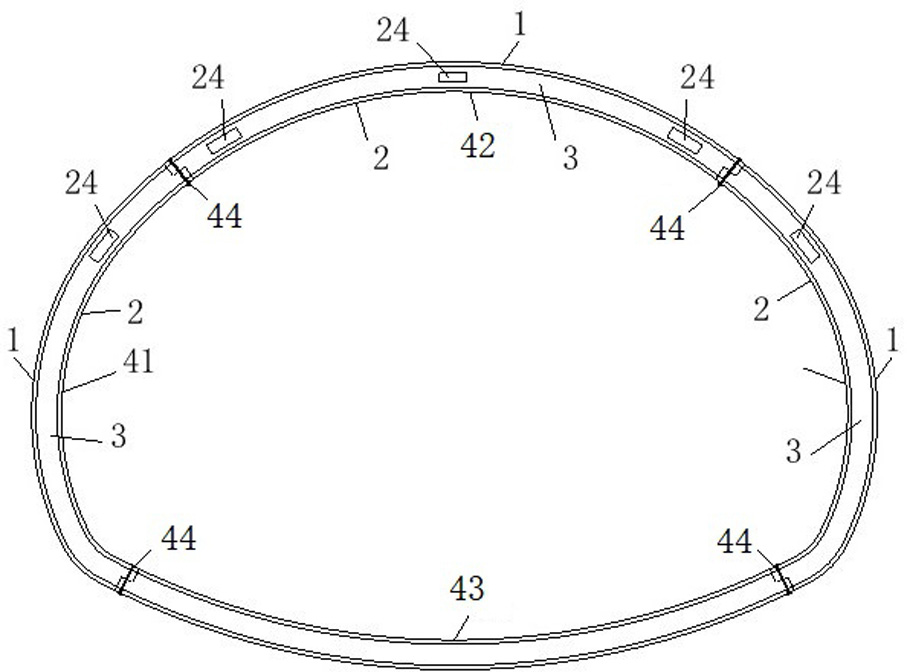

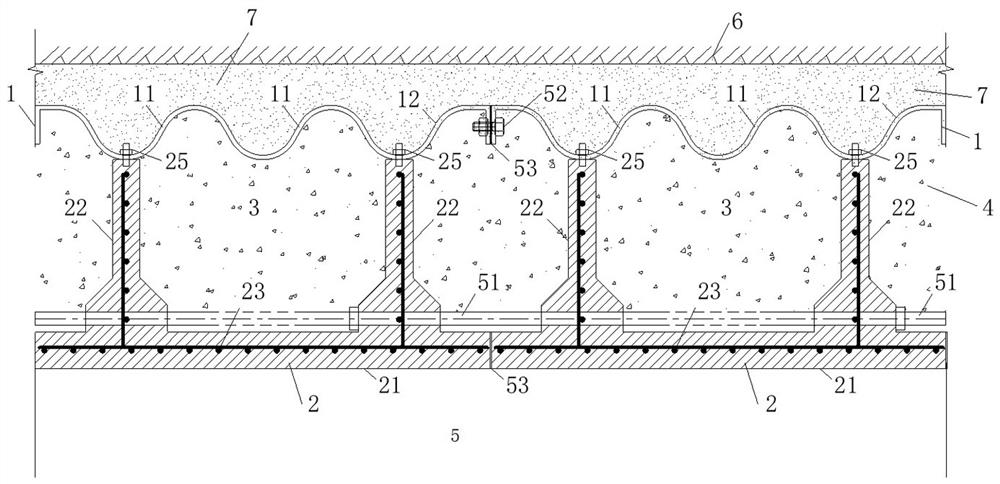

[0028] refer to Figure 1-Figure 2 .

[0029] In a preferred embodiment of the present invention: an assembled tunnel lining structure composed of corrugated steel plates and UHPC, comprising a multi-section lining unit, the lining unit includes an inverted arch at the bottom of the tunnel, and the left and right ends of the inverted arch Side wall segments are provided, and a vault segment is erected between the tops of the wall segments on both sides. Both the side wall segments and the vault segments include corrugated steel roofs and UHPC ribbed beams. The corrugated steel roofs Cement mortar is filled with the excavation surface of the tunnel to form the primary support of the tunnel, and cast-in-situ con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com