Fire-resistant silica gel material and preparation method thereof

A silica gel and fire-resistant technology, which is applied in the field of fire-resistant silica gel materials and its preparation, can solve the problems of poor fire resistance and easy fracture of flame-retardant silica gel, and achieve good flame-retardant and fire-resistant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

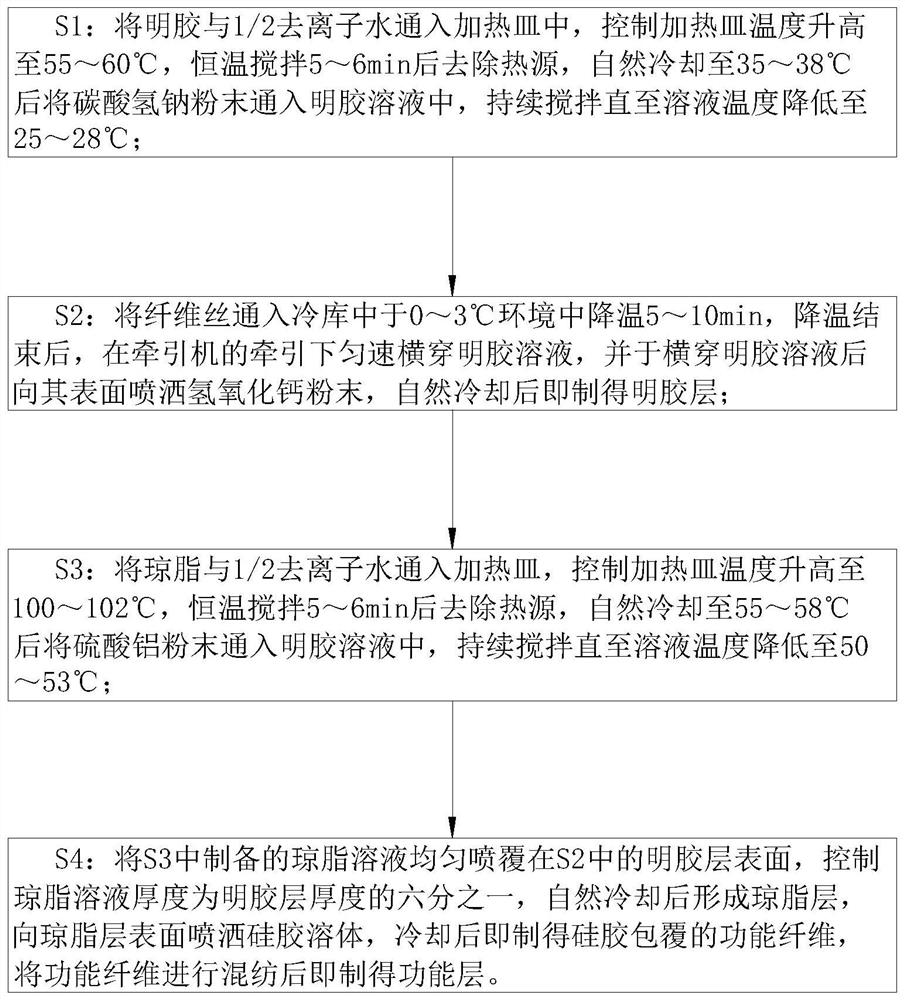

[0041] The preparation method of the functional layer comprises the following steps:

[0042] S1: Put gelatin and 1 / 2 deionized water into the heating dish, control the temperature of the heating dish to rise to 55-60°C, stir at constant temperature for 5-6 minutes, remove the heat source, cool naturally to 35-38°C, and add sodium bicarbonate Pour the powder into the gelatin solution and keep stirring until the temperature of the solution drops to 25-28°C;

[0043] S2: Pass the fiber filaments into the cold storage and cool down for 5-10 minutes in an environment of 0-3°C. After the cooling is completed, under the traction of the tractor, traverse the gelatin solution at a uniform speed, and spray hydrogen oxide on the surface after crossing the gelatin solution. Calcium powder, the gelatin layer is obtained after natural cooling;

[0044] S3: Put the agar and 1 / 2 deionized water into the heating dish, control the temperature of the heating dish to rise to 100-102°C, stir at ...

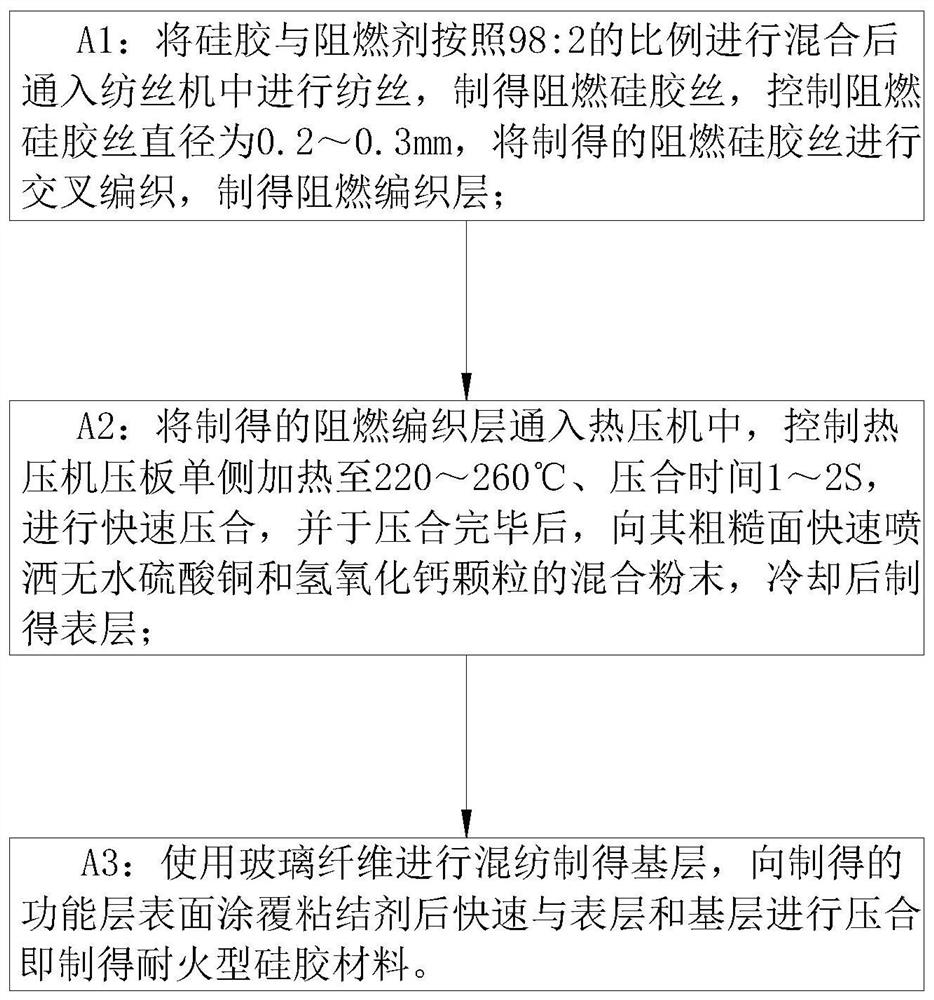

Embodiment approach

[0051] As an embodiment of the present invention, the calcium hydroxide granules are granules made by mixing calcium hydroxide, agarose and foaming agent according to the ratio of 13:25:1;

[0052] When working, calcium hydroxide particles are made by mixing calcium hydroxide, agarose and foaming agent. When the temperature rises, the agarose dissolves, and the calcium hydroxide is converted into calcium carbonate by the action of carbon dioxide. At the same time, the foaming agent makes the agar The volume of the sugar solution expands, and with the internal carbon dioxide gas, under the action of air pressure, the formed fluid-like mixture is sprayed outward along the broken pores on the surface and blocked at the pores on the surface. On the one hand, it can effectively extinguish the surface flame. The hindering effect makes the injected carbon dioxide gas form dense bubbles, enhances the fire extinguishing effect of carbon dioxide, and reduces the damage of refractory sili...

Embodiment 1

[0063] The refractory silica gel material includes a surface layer and a base layer;

[0064] The surface layer is made of flame-retardant silicone material;

[0065] The base layer is made of glass fiber material;

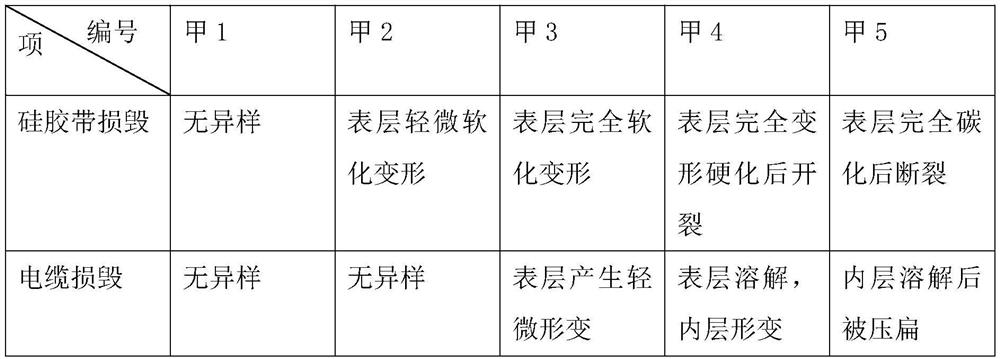

[0066] Mix the silica gel and the flame retardant according to the ratio of 98:2 and pour it on the surface of the base layer. After natural cooling to room temperature, the refractory silica gel material is obtained. After cutting the refractory silica gel material, five silica gel strips of the same size are obtained. , No. A 1~A 5, wrap five silicone tapes on the surface of five identical cables, and use a 3Kg pressure plate to press the top, use a flamethrower to heat the surface of the cable wrapped with silicone tape, and control the heating The temperature rises slowly at 3°C / S, heat A1 to A5 to 1, 2, 3, 4, and 5 minutes respectively, then stop heating, and after cooling to room temperature, observe the damage degree of the silicone tape and the damage of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com