An ultra-low noble metal loading integrated membrane electrode and its preparation method and application

A precious metal, membrane electrode technology, applied in the field of electrochemistry, can solve the problem of high cost of membrane electrodes, and achieve the effects of reducing shedding loss, avoiding peeling, and advanced preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

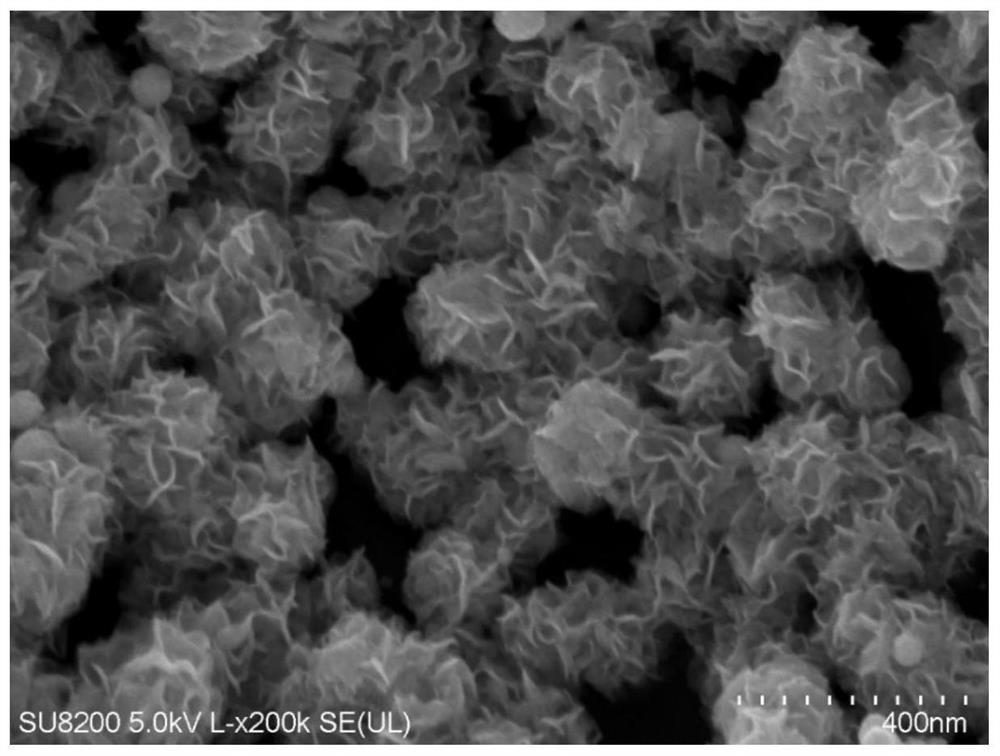

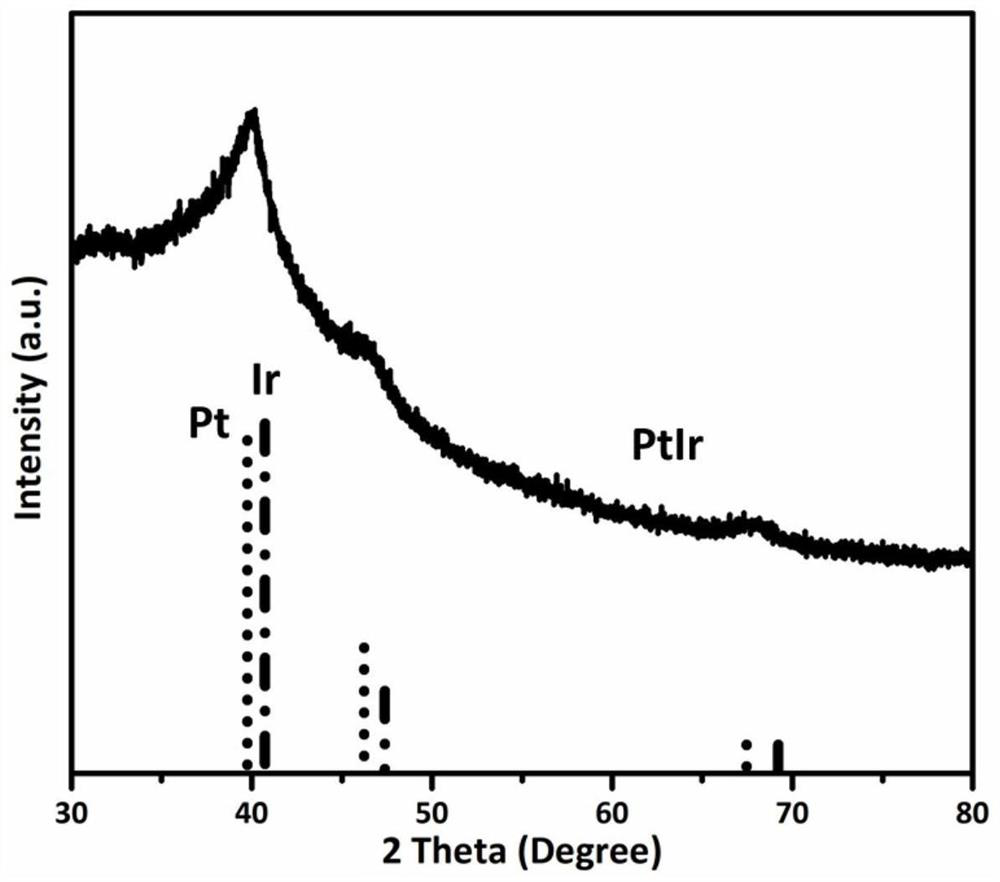

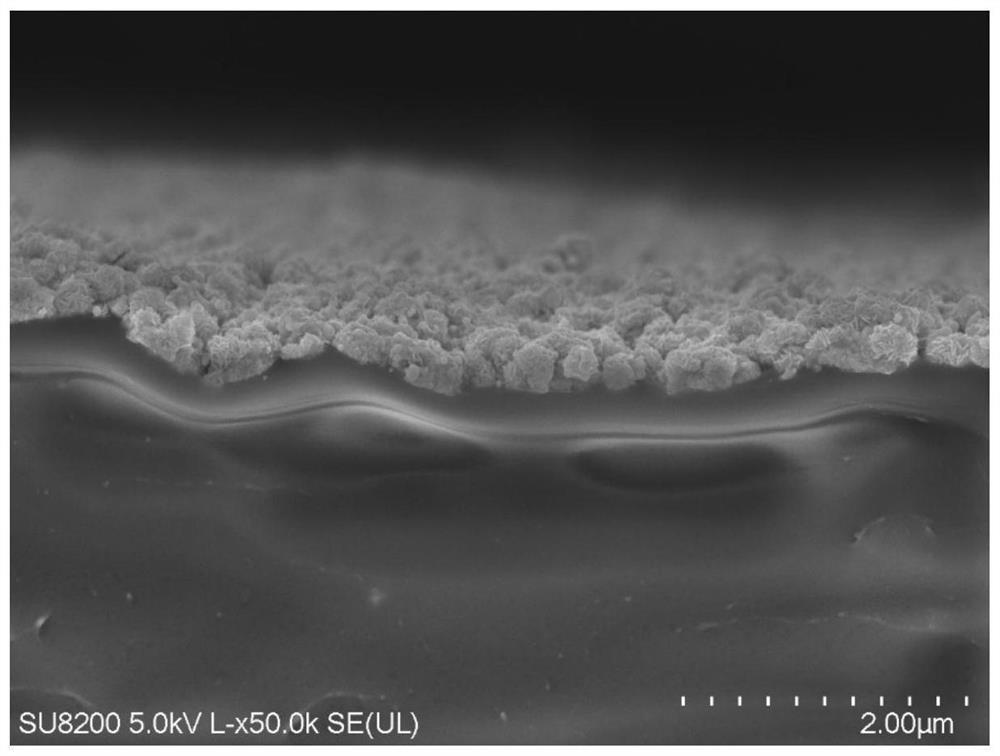

[0047] Add 0.5mL 20mmol / L chloroplatinic acid aqueous solution and 1mL 20mmol / L chloroiridic acid aqueous solution into a 10mL glass bottle, add 1.5mL 1mmol / L polyoxypropylene polyoxyethylene copolymer aqueous solution after ultrasonication for 30s, ultrasonication for 30s, and let stand After 30s, add 1.5mL of 9mol / L formic acid, obtain a mixed solution after ultrasonication, add 1mL of the mixed solution on both sides of the reaction device fixed with a 50μm thick Nafion 212 proton exchange membrane, and react at 65°C for 24h, the protons after the reaction The exchange membrane was placed in 5wt% H 2 o 2 In aqueous solution, after treatment at 80°C for 30min, soak in deionized water at 80°C for 30min, then transfer to 0.5mol / L H 2 SO 4 After treatment at 80°C for 30 minutes, soak in deionized water at 80°C for 30 minutes, dry in the air at room temperature for 30 minutes, place on a vacuum adsorption heating platform, and dry flatly at 70°C and 0.1 MPa vacuum for 15 minut...

Embodiment 2

[0054] Add 0.5mL 20mmol / L chloroplatinic acid aqueous solution and 1mL 20mmol / L chloroiridic acid aqueous solution into a 10mL glass bottle, add 1.5mL 1mmol / L polyoxypropylene-polyoxyethylene copolymer aqueous solution after ultrasonication for 30s, ultrasonication for 30s, statically After standing for 30s, add 1.5mL 9mol / L formic acid, obtain a mixed solution after ultrasonication, add 1mL mixed solution on both sides of the reaction device fixed with a 50μm thick Nafion212 proton exchange membrane, and react at 65°C for 24h, the protons after the reaction The exchange membrane was placed in 5wt% H 2 o 2 In aqueous solution, after treatment at 80°C for 30min, soak in deionized water at 80°C for 30min, then transfer to 0.5mol / L H 2 SO 4 After treatment at 80°C for 30 minutes, soak in deionized water at 80°C for 30 minutes, dry in the air at room temperature for 30 minutes, place on a vacuum adsorption heating platform, and dry flatly at 70°C and 0.1 MPa vacuum for 15 minute...

Embodiment 3

[0059] Add 0.5mL 20mmol / L chloroplatinic acid aqueous solution and 1mL deionized water into a 10mL glass bottle, add 1.5mL 1mmol / L polyoxypropylene polyoxyethylene copolymer aqueous solution after ultrasonication for 30s, ultrasonication for 30s, and add 1.5 mL9mol / L formic acid, after ultrasonication to obtain a mixed solution, take 1mL of the mixed solution and add it to one side of the reaction device fixed with a 50μm thick Nafion 212 proton exchange membrane. Add 1mL 20mmol / L chloroiridic acid aqueous solution and 0.5mL deionized water to another 10mL glass bottle, add 1.5mL 20mmol / L polyoxypropylene polyoxyethylene copolymer aqueous solution after ultrasonication for 30s, ultrasonication for 30s, and let stand for 30s Then add 1.5mL of 9mol / L formic acid and obtain a mixed solution after ultrasonication. Take 1mL of the mixed solution and add it to the other side of the reaction device fixed with a 50μm thick Nafion 212 proton exchange membrane. React at 65°C for 24h, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com