Processing technology of IBC battery with passivation contact structure

A technology of processing technology and contact structure, which is applied in the field of IBC battery processing technology, can solve the problems of metal-induced recombination increase in the grid line area, reduce battery passivation effect, and reduce battery efficiency, so as to reduce metal-induced recombination and improve battery efficiency. Efficiency, effect of reducing printing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

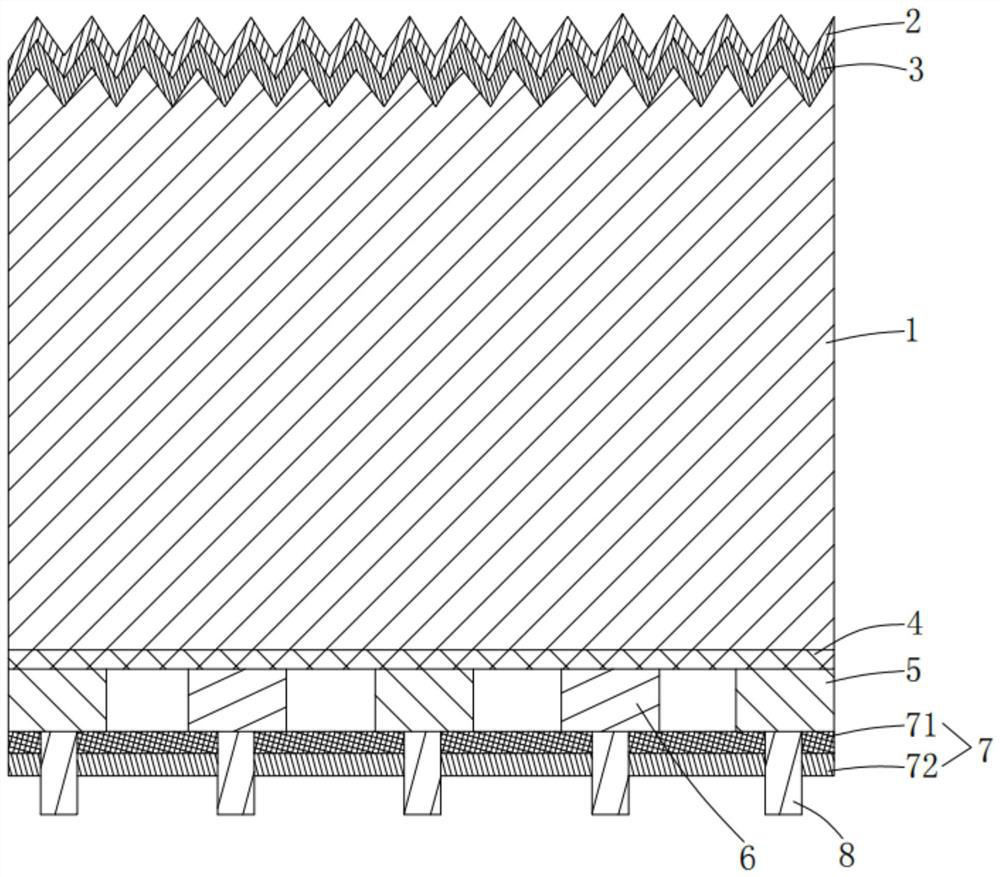

[0028] Please refer to figure 1 , the present embodiment provides an IBC battery with a passivated contact structure, comprising: an N-type monocrystalline silicon wafer 1, and the front of the N-type monocrystalline silicon wafer 1 is sequentially provided with an anti-reflection layer 2 and an N+ doped layer from top to bottom. 3. On the back of the N-type monocrystalline silicon substrate 1, tunnel oxide layers 4, N-type doped polysilicon 5 and P-type doped polysilicon 6, passivation layer 7, and N-type doped polysilicon 6 are arranged in sequence from top to bottom. The backs of the polysilicon 5 and the P-type doped polysilicon 6 are respectively provided with gate lines 8, wherein the gate lines 8 on the back side of the P-type doped polysilicon 6 are positive gate lines, and the positive gate lines form an ohmic contact with the P-type doped polysilicon 6; The gate line 8 on the back of the N-type doped polysilicon 5 is a negative gate line, which forms an ohmic contact...

Embodiment 2

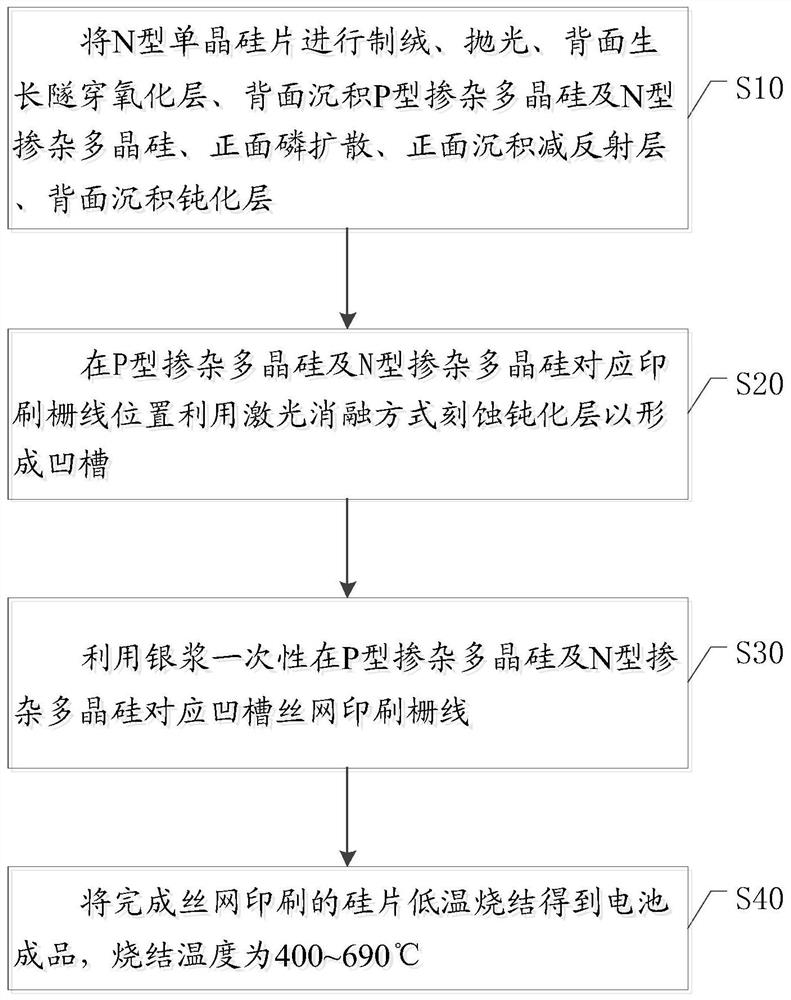

[0031] Please refer to figure 2 , the present embodiment provides a processing technology for an IBC battery with a passivated contact structure, which is used to prepare the IBC battery with a passivated contact structure in the first embodiment, comprising the following steps:

[0032] Step S10, texturing and polishing the N-type single crystal silicon wafer 1, growing a tunnel oxide layer 4 on the back side, depositing P-type doped polysilicon 6 and N-type doped polysilicon 5 on the back side, diffusing phosphorus on the front side, and depositing an anti-reflection layer on the front side 2. Deposit a passivation layer 7 on the back;

[0033] In this step, the N-type monocrystalline silicon wafer 1 is selected as the silicon wafer substrate, and the N-type monocrystalline silicon wafer 1 is textured by wet etching technology, so as to form a textured surface on the back and front of the N-type monocrystalline silicon wafer 1 , to reduce the reflection of light, which is ...

Embodiment 3

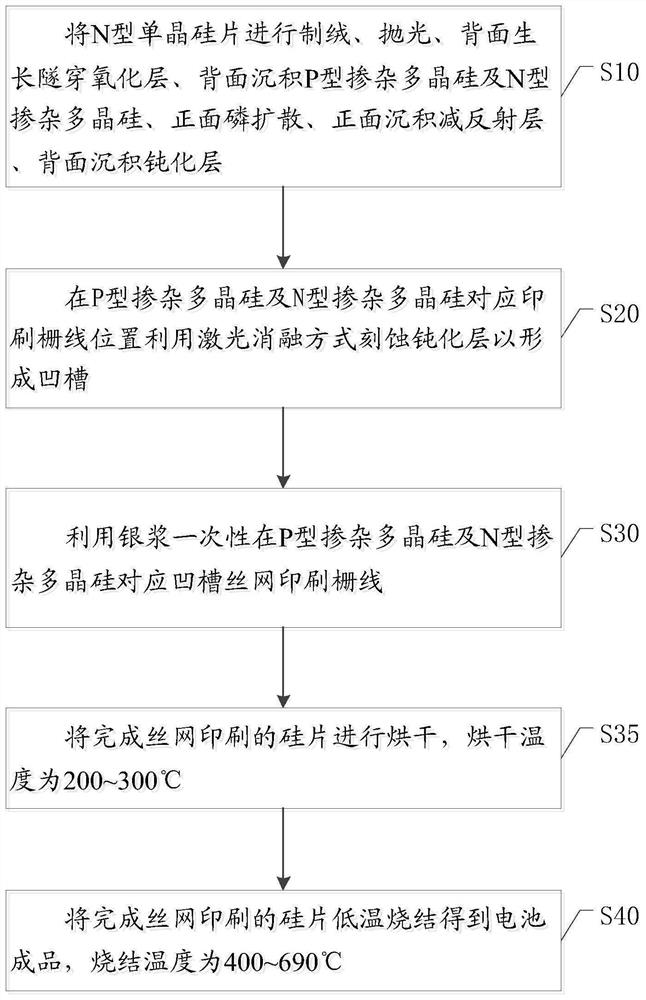

[0051] Please refer to image 3 , on the basis of Example 2, before the step of completing the low-temperature sintering of the screen-printed silicon wafer to obtain the finished battery, it also includes:

[0052] Step S35, drying the screen-printed silicon wafer at a temperature of 200-300°C.

[0053] In this embodiment, before the low-temperature sintering, the screen-printed silicon wafer is dried at a temperature of 200-300° C., which facilitates the subsequent low-temperature sintering process.

[0054] The embodiment of the present invention provides a processing technology of an IBC battery with a passivated contact structure by using laser ablation to etch the passivation layer at the positions corresponding to the printed grid lines of P-type doped polysilicon and N-type doped polysilicon to form grooves, Then use the silver paste to screen-print grid lines in the corresponding grooves of P-type doped polysilicon and N-type doped polysilicon at one time, and sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com