Gas-phase anti-corrosion cable body and gas-phase anti-corrosion steel strand inhaul cable

A steel strand, vapor phase corrosion inhibition technology, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of performance degradation, elasticity decline, large gap of anchorage, insufficient durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

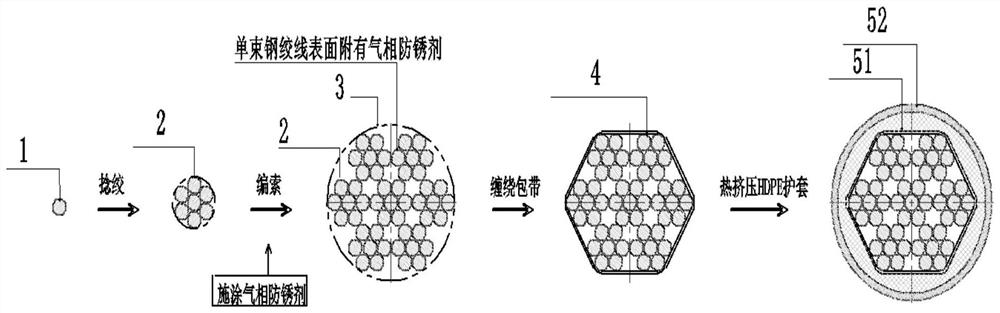

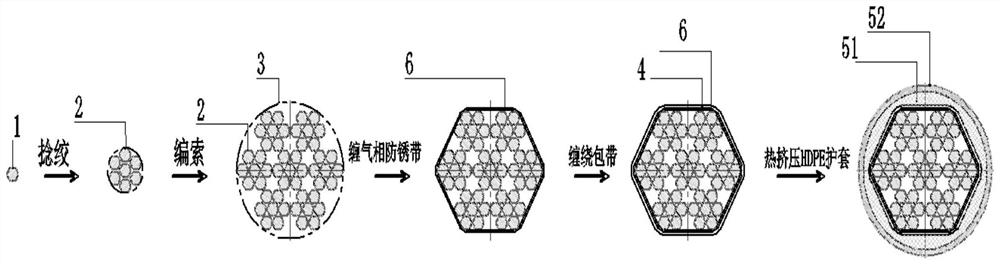

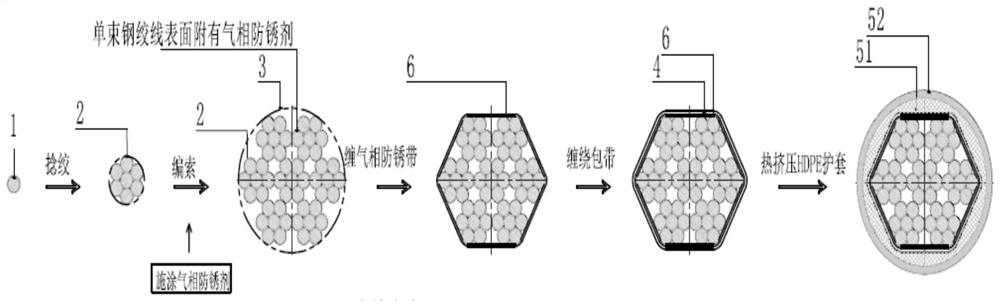

[0051] A gas-phase anti-corrosion steel strand cable disclosed by the invention is composed of a gas-phase anti-corrosion cable body and a gas-phase anti-corrosion anchor, which are respectively connected with a beam body and a bridge tower to carry and transmit bridge force. The gas-phase anti-corrosion steel strand cable is added with a gas-phase corrosion inhibitor in the structure of the cable, so that the cable has a gas-phase corrosion inhibition capability. The principle is that the gas-phase corrosion inhibitor volatilizes the corrosion-inhibiting group, and through volatilization, diffusion, and contact, it adheres to the metal surface to form an anti-corrosion protective film, thereby blocking the movement of electrons from the anode to the cathode, and inhibiting the corrosion electrochemical reaction and corrosion chemical reaction. The occurrence of corrosion inhibitor group protective film can further block the erosion of metal corrosive media to achieve the purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com